cooling_systems.ppt

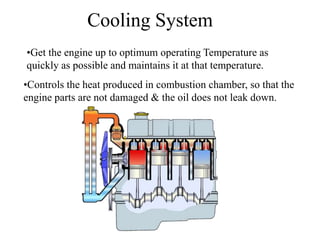

- 1. Cooling System ?Get the engine up to optimum operating Temperature as quickly as possible and maintains it at that temperature. ?Controls the heat produced in combustion chamber, so that the engine parts are not damaged & the oil does not leak down.

- 2. Engine Cooling & Car Radiator ? Heat dissipation is probably one of the most important considerations in engine design. ? An internal combustion engine creates enough heat to destroy itself. ? Without an efficient cooling system, we would not have the vehicles we do today. ? The original radiators were simple networks of round copper or brass tubes that had water flowing through them by convection.

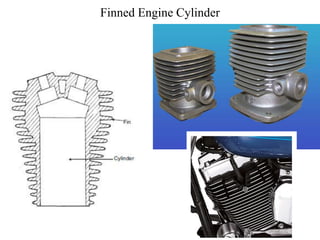

- 3. Engine Cylinder Cooling Systems ? There are mainly two types of cooling systems : ? (a) Air cooled system, and ? (b) Water cooled system.

- 4. Air Cooled System ? Air cooled system is generally used in small engines say up to 15-20 kW and in aero plane engines. ? In this system fins or extended surfaces are provided on the cylinder walls, cylinder head, etc. ? Heat generated due to combustion in the engine cylinder will be conducted to the fins and when the air flows over the fins, heat will be dissipated to air. ? The amount of heat dissipated to air depends upon : ? (a) Amount of air flowing through the fins. ? (b) Fin surface area. ? (c) Thermal conductivity of metal used for fins

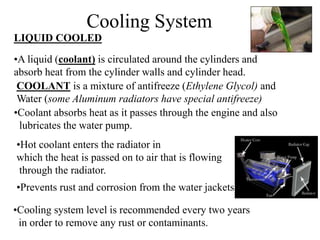

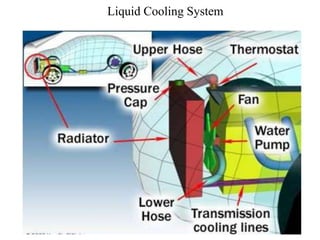

- 6. Cooling System LIQUID COOLED ?A liquid (coolant) is circulated around the cylinders and absorb heat from the cylinder walls and cylinder head. COOLANT is a mixture of antifreeze (Ethylene Glycol) and Water (some Aluminum radiators have special antifreeze) ?Coolant absorbs heat as it passes through the engine and also lubricates the water pump. ?Hot coolant enters the radiator in which the heat is passed on to air that is flowing through the radiator. ?Prevents rust and corrosion from the water jackets. ?Cooling system level is recommended every two years in order to remove any rust or contaminants.

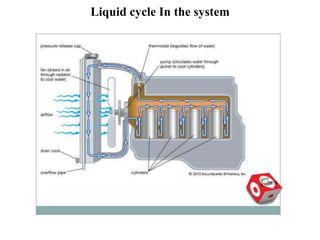

- 7. Liquid cycle In the system

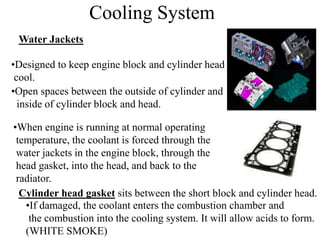

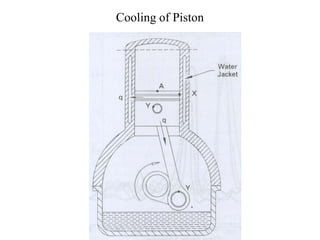

- 8. Cooling System Water Jackets ?Designed to keep engine block and cylinder head cool. ?Open spaces between the outside of cylinder and inside of cylinder block and head. ?When engine is running at normal operating temperature, the coolant is forced through the water jackets in the engine block, through the head gasket, into the head, and back to the radiator. Cylinder head gasket sits between the short block and cylinder head. ?If damaged, the coolant enters the combustion chamber and the combustion into the cooling system. It will allow acids to form. (WHITE SMOKE)

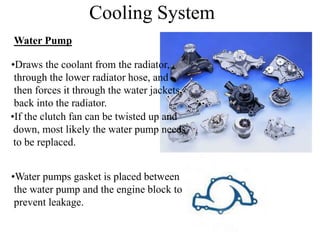

- 9. Cooling System Water Pump ?Draws the coolant from the radiator, through the lower radiator hose, and then forces it through the water jackets, back into the radiator. ?Water pumps gasket is placed between the water pump and the engine block to prevent leakage. ?If the clutch fan can be twisted up and down, most likely the water pump needs to be replaced.

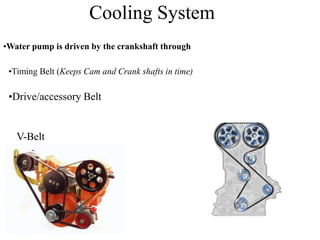

- 10. Cooling System ?Water pump is driven by the crankshaft through ?Timing Belt (Keeps Cam and Crank shafts in time) ?Drive/accessory Belt V-Belt

- 11. Cooling System Engine Fan draws air through the radiator at low speeds. Fan is mounted on the water pump and is driven by the drive belt. ?It slips at higher speed, in turn slowing the fan speed down. ?Should be able to turn when the engine is turned off. ?It locks up at slow speeds, in turn speeding up the fan RPMs.

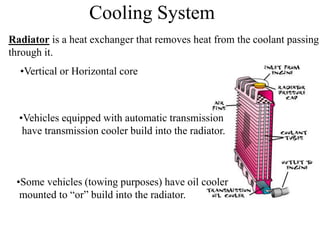

- 12. Cooling System Radiator is a heat exchanger that removes heat from the coolant passing through it. ?Vertical or Horizontal core ?Vehicles equipped with automatic transmission have transmission cooler build into the radiator. ?Some vehicles (towing purposes) have oil cooler mounted to “or” build into the radiator.

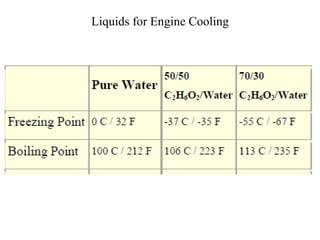

- 14. Liquids for Engine Cooling

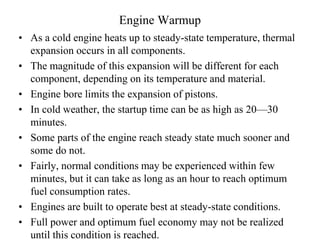

- 15. Engine Warmup ? As a cold engine heats up to steady-state temperature, thermal expansion occurs in all components. ? The magnitude of this expansion will be different for each component, depending on its temperature and material. ? Engine bore limits the expansion of pistons. ? In cold weather, the startup time can be as high as 20—30 minutes. ? Some parts of the engine reach steady state much sooner and some do not. ? Fairly, normal conditions may be experienced within few minutes, but it can take as long as an hour to reach optimum fuel consumption rates. ? Engines are built to operate best at steady-state conditions. ? Full power and optimum fuel economy may not be realized until this condition is reached.

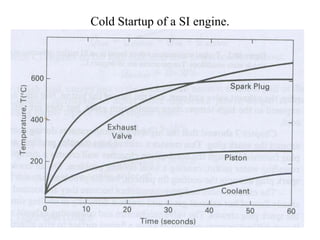

- 16. Cold Startup of a SI engine.

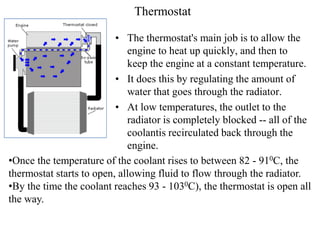

- 17. Thermostat ? The thermostat's main job is to allow the engine to heat up quickly, and then to keep the engine at a constant temperature. ? It does this by regulating the amount of water that goes through the radiator. ? At low temperatures, the outlet to the radiator is completely blocked -- all of the coolantis recirculated back through the engine. ?Once the temperature of the coolant rises to between 82 - 910C, the thermostat starts to open, allowing fluid to flow through the radiator. ?By the time the coolant reaches 93 - 1030C), the thermostat is open all the way.

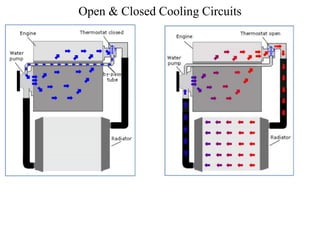

- 18. Open & Closed Cooling Circuits

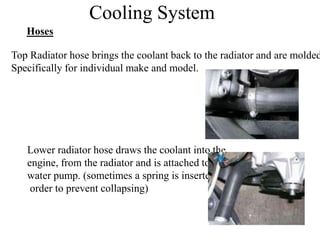

- 19. Cooling System Hoses Top Radiator hose brings the coolant back to the radiator and are molded Specifically for individual make and model. Lower radiator hose draws the coolant into the engine, from the radiator and is attached to the water pump. (sometimes a spring is inserted in order to prevent collapsing)

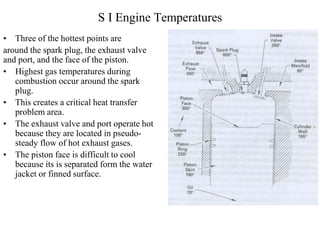

- 20. S I Engine Temperatures ? Three of the hottest points are around the spark plug, the exhaust valve and port, and the face of the piston. ? Highest gas temperatures during combustion occur around the spark plug. ? This creates a critical heat transfer problem area. ? The exhaust valve and port operate hot because they are located in pseudo- steady flow of hot exhaust gases. ? The piston face is difficult to cool because its is separated form the water jacket or finned surface.