Power of Lean

- 3. Leaning out our livesŌĆō Personal Lean Why having less can make you more efficient My 168 Business Waste The WIKA Story Removal of waste and sustainment of change Using technology to keep processes on track Real business examples of success

- 4. How many bathrooms are in your house? How often do you do Laundry? Do you batch? If you did your laundry everyday you would need 7 times less clothes than doing it once a week. Making Breakfast Have you ever thought about the distance travelled? Imagine every step is one second of your life!!! Value added versus Non Value Added ŌĆō Necessary Non Value added

- 5. By freeing ourselves of waste we create TIME and $$$$! What to do with the Time & Money you free up? Education Start a business Patent an idea Not more clothes ’üŖ Have you ever thought about what you do with the 168 hours you have each week?

- 6. You have a 168 hours in the week, what do you do with them? 56 hours sleeping 1 hour doing my hair 8 hours driving my son 3 hours cleaning/laundry 50 hours working 8 hours playing sports/buying muscles 45 hours ????? 24 hours chasing girls ’üŖ

- 7. Your perspective - Not the mediaŌƤs What is truly important in your life? For me Value is something that removes waste from my life, so I can focus on the people I care about and golf A girlfriend this would free up the 24 hours chasing girls ŌĆō net gain of 16hours to play golf

- 8. Who understands the value from their customerŌƤs perspective? Who is in the manufacturing space? Do you deal with Market Volatility? Is your company currently downsizing? Who is planning to produce or is producing offshore?

- 9. During the period of 1995 and 2002 31million factory jobs disappeared from the 20 global economies. Outsourcing and productivity gains are the reason - Did they bring expected results? Today labor is less than 10% of manufacturing cost sŌĆō down from 60 to 70% 50 years ago ŌĆō the main cost driver now is indirect labor, The greatest waste is in your business process

- 10. I joined WIKA in 1997 2001 they start their lean Journey Little Chinese guy offers them their product at less than material cost. Lean was being implemented on the manufacturing floor with great success but antiquated systems/processes were leaving tremendous waste in the business

- 11. Systems Waste Lean Business 1970 1980 1990 2000 2010

- 12. 99% of a business process is non value added (from the eye of the customer) Business processes were creating tremendous waste Forecasting Tools ŌĆō Mass Production MRP - Batch Manufacturing People spend hours reviewing data Non-value added activities were the norm

- 13. Created Flow Have customer orders feed directly into manufacturing (Real time) Level loaded manufacturing Use Kanban of high selling products to level load cells, make everything else to order Created a flexible work force Remove the departmental silos Used 2p and 3p methods in your product development

- 14. Used Business Kaizens to improve all processes Kaizen ŌĆō continuous Improvement process that works Synchronized the supply chain using Technology The competitive advantage lies in your business process ŌĆō Technology is your Friend Reduce Lead-time, increased flexibility, provided diversity.

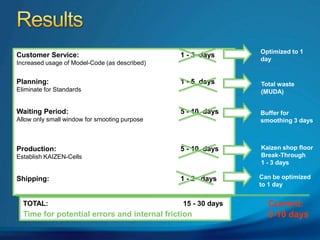

- 15. Optimized to 1 Customer Service: 1 - 3 days day Increased usage of Model-Code (as described) Planning: 1 - 5 days Total waste Eliminate for Standards (MUDA) Waiting Period: 5 - 10 days Buffer for Allow only small window for smooting purpose smoothing 3 days Kaizen shop floor Production: 5 - 10 days Break-Through Establish KAIZEN-Cells 1 - 3 days Can be optimized Shipping: 1 - 2 days to 1 day Current: TOTAL: 15 - 30 days 5-10 days Time for potential errors and internal friction

- 16. Reduced Inventory $$$ Increased Customer Satisfaction $$ Shorten lead-times $$ Productivity improvements $$$ Re-engineer business process $$$ Reduced Over-time $$$ Synchronized your organization $$ Went from 12000 production orders in 2001 to 300000+ in 2008 FREE up CASH and be innovative!

- 17. ŌĆ£When we were a batch manufacturer our forecasts got worse and worse; frequently changing demand patterns rendered them unreliable. No matter how much finished product we had, it was often the wrong stuff; customers were never really happy with our agility to react to changing demand patterns. Now we count in days.ŌĆØ Michael Gerster President WIKA Instruments

- 18. Order Accounts Pre-Plan Manufacturing Distribution Entry Receivable Order Pre- Mfg Dist A/R Entry Plan Operational Lead Time Improved Quality, Cost, & Delivery Growth In Sales & Earnings

- 19. Today I work for eBECS, where I get to apply technology and Lean in lots of great companies, Buck Knives, Royal Canadian Mint, Kriesler, Haldex, Brazeway assisted by a tremendous team..

- 21. Today we are being asked to consume more to drive the economy and help with the recovery I would argue that we have to fundamentally change and provide real value Buying more creates more debt and therefore is a short term fix We need to think less in business and in our personal lives to provide overall better value ŌĆō sustainable value Demand for food and energy will jump 50% by 2030 and for fresh water by 30%, as the world population tops 8.3 billion. Innovation and Lean are the keys to success

- 22. ┬® 2007 eBECS Limited. All rights reserved. This presentation is for informational purposes only. eBECS LIMITED MAKES NO WARRANTIES, EXPRESS OR IMPLIED, IN THIS SUMMARY.

- 23. US Census Bureau and Rochester center for economic research 'Perfect stormŌĆ× Professor Beddington ŌĆō www.bbc.c.uk Lean Enterprise Systems ŌĆō Steve Bell