How Simulation Save Money

- 1. How Simulation Save Money Giovani Haryadi giovaniharyadi@gmail.com

- 2. Experiences Company Years Project Simulation Tasks Narama 2016 Prasetya Mulya GBCI Certification 2016 Permata Tower Bintaro Cooling System Optimization 2015 Grand Indonesia Heat Transfer Simulation, Cooling System Optimization 2015 BNI Serpong GBCI Certification 2014 Pertamina Energy Tower GBCI Certification SES 2014 Kompas Tower Project manager for building efficient office tower with energy simulation as main tools 2014 Helman Miller Showcase Doing simulation for radiant cooling implementation to get more points in LEED certification Holcim Indonesia 2013 ATMI Cikarang Compare Simulation to Actual Condition 2013 Several Projects Approach Radiant Cooling Technology to owner and developer Synergy Carbon 2012 iiEXPO Energy Calculation, Chiller and Power optimization 2012 ATMI Cikarang Condensation Risk, Energy Calculation 2011 UMN Lighting System, Ventilation at Basement and overall energy consumption 2011 SC Garment Factory LEED Certification Surya Institute 2011 Surya University Energy Calculation

- 4. Building Cycle • In Design Phase, people (mostly) focus in design and construction phase. • It is good if we think about full cycle, at least until operation. • Operation in certain period cost more than design and construction phase

- 6. What’s Simulation? • Simulation through modeling is building your building in computer. • We can simulate power profile, cooling capacity needs and energy consumption by evaluating some criteria • Detailed simulation can minimized error close to 3 % in term of energy calculation

- 7. How Simulation Save Money 1. More accurate cooling capacity calculation and reduce chiller capacity 2. Getting power profile in peak period to decide electrical power installation 3. Comparing some designs to get optimum energy savings with logical investment

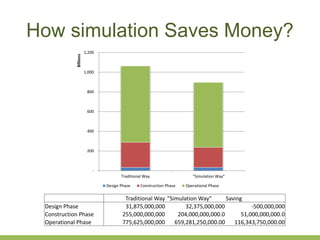

- 8. How simulation Saves Money? - 200 400 600 800 1,000 1,200 Traditional Way "Simulation Way" Billions Design Phase Construction Phase Operational Phase Traditional Way "Simulation Way" Saving Design Phase 31,875,000,000 32,375,000,000 -500,000,000 Construction Phase 255,000,000,000 204,000,000,000.0 51,000,000,000.0 Operational Phase 775,625,000,000 659,281,250,000.00 116,343,750,000.00

- 9. Case Study : ICE

- 10. ICE Modeling • Create model based on updating data

- 11. What We Saved? In Design Process : • Chiller capacity reduced from 9615 TR to 5758 TR • Power capacity (based on simulation) is 14 MVA (Before 16.7 MVA) • Glass optimization by reducing 30 % of expensive double glass usage

- 12. Thank You