Lab steps of partial denture framework construction

- 1. LAB PROCEDURES FOR FRAMEWORK CONSTRUCTION Removable partial denture

- 2. LAB PROCEDURES FOR FRAMEWORK CONSTRUCTION Removable partial denture

- 3. ? Framework fabrication delegated to a technician located outside the dental office. ? Therefore, effective communication between the dentist and the technician is essential. Removable partial denture Lap Procedures

- 4. ? For successful construction of a removable partial denture, the dentist must provide dental laboratory with the following: ? (1) a written work authorization describing the desired Prosthesis ? (2) a properly articulated and surveyed diagnostic cast with appropriate partial denture design ? (3) a properly master cast that provides an accurate reproduction of hard and soft tissue. Removable partial denture Lap Procedures

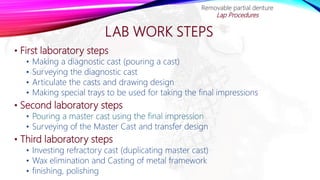

- 5. LAB WORK STEPS ? First laboratory steps ? Making a diagnostic cast (pouring a cast) ? Surveying the diagnostic cast ? Articulate the casts and drawing design ? Making special trays to be used for taking the final impressions ? Second laboratory steps ? Pouring a master cast using the final impression ? Surveying of the Master Cast and transfer design ? Third laboratory steps ? Investing refractory cast (duplicating master cast) ? Wax elimination and Casting of metal framework ? finishing, polishing Removable partial denture Lap Procedures

- 6. PRIMARY IMPRESSIONS STUDY MODELS SPECIAL TRAYS Removable partial denture Lap Procedures

- 7. SURVEYING DENTURE DESIGN Removable partial denture Lap Procedures

- 8. TOOTH PREPARATION FINAL IMPRESSION Removable partial denture Lap Procedures

- 9. FINAL IMPRESSIONS MASTER CASTS Removable partial denture Lap Procedures

- 10. RETRIPODING THE MASTER CAST ? During the survey and design process, the clinician determines a specific path of insertion and removal for the partial denture. ? This path is recorded by placing tripod marks on the diagnostic cast. Removable partial denture Lap Procedures

- 11. RETRIPODING THE MASTER CAST Removable partial denture Lap Procedures

- 12. RETRIPODING THE MASTER CAST ? Placing three easily identifiable marks on the same horizontal plane. ? These marks must be widely separated and must be positioned on anatomic portions of the diagnostic cast ? they allow rapid reorientation of the diagnostic cast. ? permits orientation of the master cast and reproducing the prescribed path of insertion Removable partial denture Lap Procedures

- 13. DESIGN TRANSFER ? Without removing the master cast from the survey table or changing the tilt, the technician transfers the design from the diagnostic cast to the master cast with extreme care and clearly marked to avoid confusion. Removable partial denture Lap Procedures

- 14. ?Block out is the act of placing wax and other materials into undesirable undercuts on the master cast. Removable partial denture Lap Procedures

- 15. CAST PREPARATION Removable partial denture Lap Procedures Before the addition of the blockout wax, ? maxillary cast is beaded to ensures positive contact of the major connector with the palatal tissues. ? master cast treated with a surface sealer to provides a film protects design through blockout and duplication processes.

- 16. BLOCKOUT TECHNIQUE ? Wax is placed apical to the height of contour and is not applied in areas where intimate metal contact is desired. Removable partial denture Lap Procedures

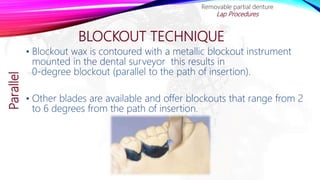

- 17. BLOCKOUT TECHNIQUE ? Blockout wax is contoured with a metallic blockout instrument mounted in the dental surveyor this results in 0-degree blockout (parallel to the path of insertion). ? Other blades are available and offer blockouts that range from 2 to 6 degrees from the path of insertion. Removable partial denture Lap ProceduresParallel

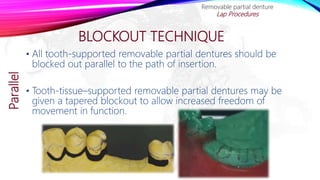

- 18. BLOCKOUT TECHNIQUE ? All tooth-supported removable partial dentures should be blocked out parallel to the path of insertion. ? Tooth-tissue¨Csupported removable partial dentures may be given a tapered blockout to allow increased freedom of movement in function. Removable partial denture Lap ProceduresParallel

- 19. BLOCKOUT TECHNIQUE ? wax shaped with hand instruments on buccal and lingual surface to provide a slight ledge just apical to the clasp terminus This guides the placement of the wax pattern accurately. Removable partial denture Lap Proceduresshaped

- 20. BLOCKOUT TECHNIQUE ? Areas of undercut that are not directly involved with framework fabrication also must be addressed to minimize distortions during cast duplication. Removable partial denture Lap ProceduresArbitrary

- 21. BLOCKOUT TECHNIQUE ? Wax is used to create a space between the framework and soft tissue in edentulous area to provide for attachment of acrylic denture bases ? Wax is also used beneath lingual bars and in other area such as maxillary and mandibular tori. Removable partial denture Lap ProceduresRelief

- 22. DUPLICATION ? Duplication materials and techniques are alloy specific. ? low heat alloys are use gypsum-bound refractory materials that use reversible hydrocolloid for duplication . ? high-heat alloys use phosphate-bound investments and glycerin- based colloids for duplication. Removable partial denture Lap Procedures

- 23. REFRACTORY CAST ? Gypsum-bonded refractory materials (low heat investments) are used for casting Type IV partial denture gold and Ticonium and can be heated to 704ˇăC. ? Refractory materials used for Vitallium, chrome cobalt alloys, and titanium alloys (high-heat investments) can be heated to1037ˇăC Removable partial denture Lap Procedures

- 24. REFRACTORY CAST ? After removal, the refractory cast is placed in a drying oven at 93ˇăC for 30 to 60 minutes . ? The dry refractory cast is dipped into beeswax at138ˇăC to 149ˇăC for 15 seconds to ensure a smooth, dense surface. Removable partial denture Lap Procedures

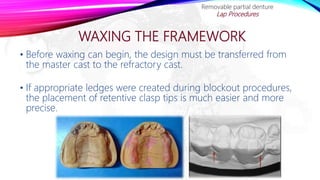

- 25. WAXING THE FRAMEWORK ? Before waxing can begin, the design must be transferred from the master cast to the refractory cast. ? If appropriate ledges were created during blockout procedures, the placement of retentive clasp tips is much easier and more precise. Removable partial denture Lap Procedures

- 26. WAXING THE FRAMEWORK ? The plastic patterns are ˇ°gluedˇ± to the refractory cast with a mixture of acetone and plastic pattern scraps mixed to a watery consistency (tacky liquid). Removable partial denture Lap Procedures

- 27. WAXING THE FRAMEWORK ? Some care is required to remove these prefabricated patterns without distorting them. ? It is important that retentive clasp patterns are not distorted because the shape of the clasp greatly affects flexibility. ? After the plastic patterns have been placed on the refractory cast, they must be adapted without distortion. Removable partial denture Lap Procedures

- 28. WAXING THE FRAMEWORK ? At every step, the technician must exercise extreme care not to stretch the pattern. ? A blade is used to trim pattern material that extends beyond the outline drawn on the cast. ? these patterns must be joined using wax that used to seal the margins of the major connector and to create the minor connectors and rests. Removable partial denture Lap Procedures

- 29. SPRUING THE FRAMEWORK ? The location and geometry of the sprue former is based upon recommendations of the alloy manufacturer. Removable partial denture Lap Procedures

- 30. SPRUING THE FRAMEWORK ? Ticonium is cast using a single sprue former that approaches through the refractory cast. ? Type IV gold and chrome-cobalt alloys are cast using a sprue that approaches from above and gives rise to a number of smaller, accessory sprues. Removable partial denture Lap Procedures

- 31. INVESTING THE REFRACTORY CAST ? Some systems require a two-part investment process, the first part being a 3- to 4-mm ˇ°paint-onˇ± layer that is carefully brushed onto the waxed refractory cast to ensure that no voids are present. Removable partial denture Lap Procedures

- 32. INVESTING THE REFRACTORY CAST ? An investment ring large enough to accommodate the refractory cast and its first layer is selected. An appropriate amount of refractory material is measured, mixed, and placed into the investment ring. Removable partial denture Lap Procedures

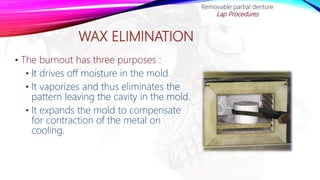

- 33. WAX ELIMINATION ? The burnout has three purposes : ? It drives off moisture in the mold. ? It vaporizes and thus eliminates the pattern leaving the cavity in the mold. ? It expands the mold to compensate for contraction of the metal on cooling. Removable partial denture Lap Procedures

- 34. CASTING ? The metal is melted by heat and forced into the mold cavity by force. Removable partial denture Lap Procedures

- 35. CASTING ? Heat may be applied by a blowtorch using gas air ,gas and oxygen, acetylene, electric conduction or induction. ? Force may be Centrifugal or air pressure. ? Induction casting is the method of choice for base metal alloys. Removable partial denture Lap Procedures

- 36. CASTING Removable partial denture Lap Procedures

- 37. CASTING RECOVERY Removable partial denture Lap Procedures ? the mold is removed and allowed to cool ? the outer layer of refractory material is removed by tapping it with a mallet ? The remaining investment is removed by airborne particle abrasion

- 38. FINISHING THE FRAMEWORK Sprue removal ? Using high-speed lathes and large abrasive disks Removable partial denture Lap Procedures

- 39. FINISHING THE FRAMEWORK Finishing ? Nodules are removed from the surfaces that will contact the teeth. ? Rubber wheels and points are used to give the framework a ˇ°satinˇ± finish. ? Technician uses coarser disks and stones and then proceeds to finer grinding agents Removable partial denture Lap Procedures

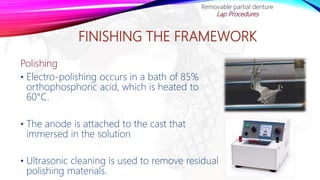

- 40. FINISHING THE FRAMEWORK Polishing ? Electro-polishing occurs in a bath of 85% orthophosphoric acid, which is heated to 60ˇăC. ? The anode is attached to the cast that immersed in the solution ? Ultrasonic cleaning is used to remove residual polishing materials. Removable partial denture Lap Procedures

- 41. Removable partial denture Lap Procedures