Labeler Guide

?

1 like?405 views

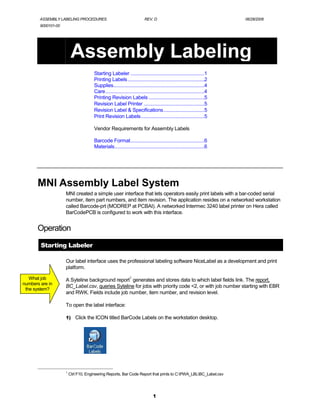

The document describes assembly labeling procedures including: 1. Using labeling software to print labels with a barcoded serial number, item number, and revision from production data. 2. Specifications for labels, ribbons, and a separate printer for revision labels. 3. Requirements for vendors including unique barcoded serial numbers in a standardized format.

1 of 6

Download to read offline