Mixed In-House and Outsourced Manufacturing

- 1. T H E P A S S I O N R U NS D E E P Stuart Patsos, CIO / Vice President of IT Achieving Success with Mixed In-House and Outsourced Manufacturing

- 2. Company Background (Cont.) Macsteel Service Centers USA is one of the leading metals processors and distributors in North America. A division of Kloeckner & Co ¨C the largest mill-independent distributor of steel in the world ˇń 30+ locations throughout North America and Puerto Rico ˇń processes and distributes ? carbon ? aluminum ? stainless ? specialty metals ˇń Products include a full range of ? flat rolled ? pipe ? plate ? bar ? tubing ? structurals ˇń The company also supplies a full range of ? Coated ? steel building products ? prepainted metals 2 2

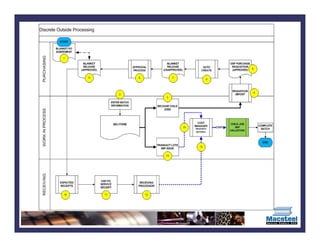

- 3. Outside Processing ? Purchase Order Requirements ¨C A Purchase order may or may not be placed at the same time as the material order or the transfer order. ¨C The Raw material is sent to the processor for storage and the processing requirements are specified later. ? The PO for Outside Processing must support: ¨C Ability to reference Item to be processed and Item to be consumed for Processing ¨C Multiple Units of Measure for produced of Pcs, Lbs, FT, CWT ¨C Multiple acquisition costs specified to vendor. ¨C Reference between documents PO and WO

- 4. Outside Processing ? Acquisition Costs (Landed Cost) ¨C PO Line item Acquisition costs supports positive and negative values that may include processing charge, skids, packaging, and other charges. ¨C Freight costs associated with transferring inventory from one Warehouse to an Outside Processing Warehouse are reflected in the inventory at the receiving location.

- 5. Outside Processing ? Material Movement ¨C Material dropped shipped from Vendor directly to the Outside Processor. ¨C Material may be shipped from our Warehouse to the Outside Processor for storage or processing ¨C Transportation costs treated as acquisition costs (LCM)

- 6. Outside Processing ? Material Costing & Traceability ¨C Product and Material Cost is Perpetual Average costing ¨C Material Conversion from Ingredient to Product rolls all costs of the parent item plus associated processing costs. ¨C Traceability between parent and child ¨C Supports ˇ®Bought-ForˇŻ reference on Tag ¨C Use ProcessorˇŻs tag number instead of Macsteel Tag Number ¨C Heat information associated with the parent tag is transferred to the produced tag

- 7. Outside Processing ? Inventory Management ¨C Inventory received or produced into OSP Org will use the vendor Lot Number instead of internal lot number. ¨C View allocation of raw material assigned to make product at OSP vendor and the details of the scheduled receipts of product(s) being made along with PO charges ¨C Inventory Inquiry: Purchase Orders placed to an Outside Processor for a Product and Dimension should be viewable for the item placed on the services purchase order. ¨C When a user queries an item to be processed on a services PO the item can be seen as incoming material and the user can view the PO item associated with the incoming quantity.

- 8. Outside Processing ? Full Visibility ¨C Full Visibility and status including qty processed, scheduled receipts and completions or partial balances. ¨C Assigned lot numbers. ¨C All PO Charges and balances updated to reflect production completions, shipments and remaining balances

- 9. Outside Processing ? More scalability and flexibility to work with multiple items and multiple transactions ¨C One to many conversions of number of parts processed, for By- products and Co-products ¨C Transfer from one processing vendor to multiple vendors and drop ships at completions ¨C Addition of Product Item numbers to capture individual process costs by product/item