Resume_nepdf

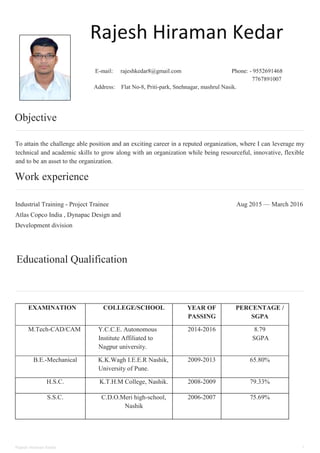

- 1. Rajesh Hiraman Kedar 1 Rajesh Hiraman Kedar E-mail: rajeshkedar8@gmail.com Phone: - 9552691468 7767891007 Address: Flat No-8, Priti-park, Snehnagar, mashrul Nasik. Objective To attain the challenge able position and an exciting career in a reputed organization, where I can leverage my technical and academic skills to grow along with an organization while being resourceful, innovative, flexible and to be an asset to the organization. Work experience Industrial Training - Project Trainee Atlas Copco India , Dynapac Design and Development division Aug 2015 — March 2016 Educational Qualification EXAMINATION COLLEGE/SCHOOL YEAR OF PASSING PERCENTAGE / SGPA M.Tech-CAD/CAM Y.C.C.E. Autonomous Institute Affiliated to Nagpur university. 2014-2016 8.79 SGPA B.E.-Mechanical K.K.Wagh I.E.E.R Nashik, University of Pune. 2009-2013 65.80% H.S.C. K.T.H.M College, Nashik. 2008-2009 79.33% S.S.C. C.D.O.Meri high-school, Nashik 2006-2007 75.69%

- 2. Rajesh Hiraman Kedar 2 Projects [A] Design Modification in "Tractor-Frame" Of Dynapac Single Drum Vibratory Road Roller: - Objective of the project is to optimize thickness of different plates of chassis by Static and Dynamic analysis followed by FEM analysis. Also possible modifications within chassis & optimize thickness of side plates of fuel-tank. Atlas Copco India, Dynapac design and development division, Satpur MIDC Nasik. [B] “Quality improvement of steel rods”:- By analyzing all processes, reducing defects in production process, modifying necessary processes. Ring’s formation, Slag entrapment within the rod were the main issue found which are then solved by modifying ESR process and Automation in ESR process. It resulted in increase of yield by 5 % that directly benefited company cost saving 18.2 Rs/Kg for 1000 Kg of Melting in ESR process. Also On field benefits like reduction in energy consumption, time and labor cost of reworking. Apart from this, suggestion was given to maintain Composition of different alloying elements to average side earlier it was on higher side that results into cost saving of 9.05 Rs/Kg for 650Kg M2 material lot. Use of lid for induction furnace was suggested to avoid loss of heat by radiation& convection and to avoid oxidation of molten metal. Nashik Steel Pvt Ltd, Ambad MIDC Nashik [C] Seminar on “Application of Cad/Cam in Dentistry”:-Cad/Cam overcomes problems in Traditional Restoration technique, Methods of Manufacturing of Cad/Cam in Dentistry. [D] Seminar on “Regenerative Braking System”:-To reuse energy with help of storage device, which is Wasted During breaking by using Regenerative Braking System. Extra-Curricular Activities  Participated In two day workshop on “Hands on Ansys” by Dr.D.M.Kulkarni Bits Pillani Goa, organized By Mechanical department Yashwantrao Chavan College of engineering Nagpur.  Participated In one day workshop on “Excelling in FPL” organized by ISTE students chapter.  Participated in Interbranch Cricket Tournament representing mechanical dept. K.K.W.I.E.E.R.  Participated In Mudbotix, Targetrix, Bullz eye National level Technical event Mecheaven organized by mechanical dept K.K.W.I.E.E.R. Other  Published research paper on "Static Analysis of Single Drum Vibratory Soil Compactor Chassis" as conference proceeding International Conference On Advances in Dynamics, Vibration And Control (ICADVC 2016) 25th -27th Feb 2016 Organized by NIT Durgapur West Bengal, published by Narosa Publishing house,ISBN 978-81-8487-550-8.  Worked as Co-Head of Mecheaven’12 organized by mechanical Dept.K.K.Wagh College.  Secured Best Mechanism position in event Targetrix Mecheaven’12 Organized by mechanical Dept.K.K.Wagh College.

- 3. Rajesh Hiraman Kedar 3 Software Knowledge  Catia (IGTR- Nagpur)  AutoCAD  Pro-E / Creo  Ansys  Master Cam Interests  Playing & Watching Cricket.  Watching Movies.  Organizing data in my computer in my leisure time.  Playing chess. Personal Details  Date of birth : 31st Aug 1991  Sex : Male  Marital Status : Bachelor  Languages Known : English, Hindi and Marathi. Declaration I consider myself familiar with Mechanical Engineering Aspects. I am also confident of my ability to work in a team. I hereby declare that the information furnished above is true to the best of my knowledge. Date: Place: (Rajesh H. Kedar)

![Rajesh Hiraman Kedar 2

Projects

[A] Design Modification in "Tractor-Frame" Of Dynapac Single Drum Vibratory Road Roller: -

Objective of the project is to optimize thickness of different plates of chassis by Static and Dynamic analysis

followed by FEM analysis. Also possible modifications within chassis & optimize thickness of side plates of

fuel-tank. Atlas Copco India, Dynapac design and development division, Satpur MIDC Nasik.

[B] “Quality improvement of steel rods”:- By analyzing all processes, reducing defects in production

process, modifying necessary processes. Ring’s formation, Slag entrapment within the rod were the main

issue found which are then solved by modifying ESR process and Automation in ESR process. It resulted in

increase of yield by 5 % that directly benefited company cost saving 18.2 Rs/Kg for 1000 Kg of Melting in

ESR process. Also On field benefits like reduction in energy consumption, time and labor cost of reworking.

Apart from this, suggestion was given to maintain Composition of different alloying elements to average side

earlier it was on higher side that results into cost saving of 9.05 Rs/Kg for 650Kg M2 material lot. Use of lid

for induction furnace was suggested to avoid loss of heat by radiation& convection and to avoid oxidation of

molten metal. Nashik Steel Pvt Ltd, Ambad MIDC Nashik

[C] Seminar on “Application of Cad/Cam in Dentistry”:-Cad/Cam overcomes problems in Traditional

Restoration technique, Methods of Manufacturing of Cad/Cam in Dentistry.

[D] Seminar on “Regenerative Braking System”:-To reuse energy with help of storage device, which is

Wasted During breaking by using Regenerative Braking System.

Extra-Curricular Activities

 Participated In two day workshop on “Hands on Ansys” by Dr.D.M.Kulkarni Bits Pillani Goa, organized

By Mechanical department Yashwantrao Chavan College of engineering Nagpur.

 Participated In one day workshop on “Excelling in FPL” organized by ISTE students chapter.

 Participated in Interbranch Cricket Tournament representing mechanical dept. K.K.W.I.E.E.R.

 Participated In Mudbotix, Targetrix, Bullz eye National level Technical event Mecheaven organized by

mechanical dept K.K.W.I.E.E.R.

Other

 Published research paper on "Static Analysis of Single Drum Vibratory Soil Compactor Chassis" as

conference proceeding International Conference On Advances in Dynamics, Vibration And Control

(ICADVC 2016) 25th -27th Feb 2016 Organized by NIT Durgapur West Bengal, published by Narosa

Publishing house,ISBN 978-81-8487-550-8.

 Worked as Co-Head of Mecheaven’12 organized by mechanical Dept.K.K.Wagh College.

 Secured Best Mechanism position in event Targetrix Mecheaven’12 Organized by mechanical

Dept.K.K.Wagh College.](https://image.slidesharecdn.com/e1bd9392-167b-42dd-b447-8d7a9fe0c1d8-160423084012/85/Resume_nepdf-2-320.jpg)