Stuart Csl Risk Assessment

- 1. Chemical Safety Levels: A tool whose time has come? R. Stuart

- 2. Laboratory Risk Assessment - or - Who Needs a Hood? Ralph Stuart, Univ of Vermont

- 3. The Laboratory Safety Challenge  Ever-evolving chemical selection and process  Lab walls are getting thinner, both figuratively and literally  Turnover – 20% per year in academia  The educational culture currently doesn’t include risk assessment: but it can

- 4. Stakeholders in Laboratory Risk Assessment   Laboratory workers (personal safety and efficient work)   Laboratory upper management (financial and carbon issues)   Laboratory designers (design choices)   Laboratory building operators (personal safety and operations costs)   Emergency responders (emergency planning and response)

- 5. Emerging Issues in Lab Risks   Ventilation design and energy costs   Optimum ACH   Hood design goals   Building operation   Protection of maintenance staff   Building operations costs   Education of lab staff about their buildings   Re- and retro- commissioning   Emergency planning and response   Pre-plans   Scene assessment   Response rate: 1 emergency response/250 lab-years   Do these challenges point the way from risk assessment to control banding?   Addressing these issues requires development ofbroader understanding and language for lab chemical risks

- 6. Lab Planning and Design: Moving beyond Tradition   The traditional engineering approach uses a lot of energy without much thought   Control Banding: Define Chemical Safety Levels from 1 to 4   For many purposes, the control band deals with a collection of chemicals rather than a specific biological agent   The result is a general guideline to appropriate protections (which is likely to need modification, e.g CSL 2+)

- 7. Chemical Risk Assessment   Flammability   Concentrations of concern tend to be a few percent by volume   Corrosivity   Particles with kinetic energy are much harder to control than vapors   Reactivity   Requires chemical and process specific literature review   Toxicity   Concentrations of concern range from 1000 ppm to 0.5 ppm to ALARA   GHS will help this process

- 8. Chemical Protection Strategies   Change the chemical – limited opportunities in the research setting   Engineering controls   General Ventilation   Flammable cabinets   Local Ventilation   Chemical Hoods   Administrative Controls and Oversight   20% turnover/year in academic labs   Personal Protective Equipment   Traditionally, in chemistry laboratories, fume hood + PPE = “as safe as can be”

- 9. Factors to Consider in Selecting a CSL:   Flammability (via MSDS):   check flashpoint (is it below ambient temperature?)   If yes, are expected airborne concentrations above LEL?  Corrosivity (via pH of solutions):   pHs < 2 or > 10.5 require special handling   Consider alsos spattering and off-gassing from reactions  Reactivity (via MSDS and literature review)   Check potential interactions and contamination concerns  Toxicity (via MSDS and other sources)   Review PELs, TLVs, IDLHs and assess against anticipated concentrations   Consider potential interactions   ALARA for irreversible hazards (cancer, birth defects, sensitization)

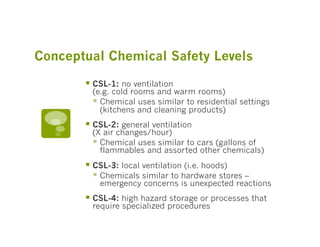

- 10. Conceptual Chemical Safety Levels   CSL-1: no ventilation (e.g. cold rooms and warm rooms)   Chemical uses similar to residential settings (kitchens and cleaning products)   CSL-2: general ventilation (X air changes/hour)   Chemical uses similar to cars (gallons of flammables and assorted other chemicals)   CSL-3: local ventilation (i.e. hoods)   Chemicals similar to hardware stores – emergency concerns is unexpected reactions   CSL-4: high hazard storage or processes that require specialized procedures

- 11. Determining the CSL Hazard Fire Corrosivity Reactivity Toxicity CSL 1 Flashpoint 2 < pH < 10.5 No chemical changes All chemicals have below ambient expected in the process known toxicities and TLV’s > 500 ppm CSL 2 Flashpoint near pH <2 or No known All chemicals have ambient, pH >10.5 incompatibilities between known toxicities and expected chemicals being used 10 ppm <TLV’s < concentration < 500 ppm 10% LEL CSL 3 Expected Use of heated Chemicals with known Unknown toxicities concentration > corrosives reactions or or OEL < 10 ppm 10% LEL contamination hazards present CSL 4 High hazard reactions in Irreversible toxicities use require use of designated areas

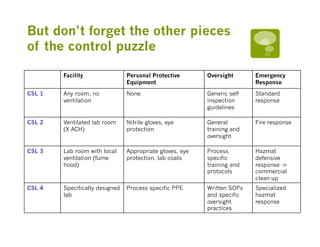

- 12. But don’t forget the other pieces of the control puzzle Facility Personal Protective Oversight Emergency Equipment Response CSL 1 Any room, no None Generic self Standard ventilation inspection response guidelines CSL 2 Ventilated lab room Nitrile gloves, eye General Fire response (X ACH) protection training and oversight CSL 3 Lab room with local Appropriate gloves, eye Process Hazmat ventilation (fume protection, lab coats specific defensive hood) training and response -> protocols commercial clean-up CSL 4 Specifically designed Process specific PPE Written SOPs Specialized lab and specific hazmat oversight response practices

- 13. Implementation at the lab level: A Risk Assessment Spreadsheet

- 14. At the Campus Level, CSL’s can be used to:   Establish an inventory of laboratory rooms in place   Preliminary estimate for non-chemistry buildings, 75% CSL 2 labs   Support design standards for new and renovated lab settings.   Improve training and emergency planning.   Support communication between lab workers and facility and emergency support services.   Plan for climate actions appropriate to the campus.

- 15. Next Steps  Complete a risk assessment tool that addresses the questions of various stakeholders  Define the boundaries between the various CSL’s and where those boundaries blur  Develop guidance documents for use of CSL’s