Explosion welding

- 2. Contents: âĒ Introduction âĒ Component Terminology âĒ Principle âĒ Types âĒ Working âĒ Explosive material âĒ Advantages & Disadvantages âĒ Applications âĒ Common industries that use âĒ Examples âĒ references

- 3. Introduction: âĒ Explosion welding is also a solid state welding process. âĒ Welding occurs without application of external heat. âĒ No addition of filler material. âĒ It is mainly used to join large surface area of dissimilar materials.

- 4. Component Terminology: âĒ Base plate. âRemains stationary âSupported by anvil âĒ Flyer plate. âThis is another welding plate which is going to be weld on base plate.

- 5. âĒAnvil: Surface of which the base plate rests during explosion âĒStandoff Distance: Stand-off distance plays a vital role in explosion welding.

- 6. âĒ Buffer plate:Buffer plate is situated on the flyer plate. âĒ Explosive: is placed over the flyer plate. This explosive is situated in a box structure. âĒ Velocity of detonation: It is the rate at which the explosive detonate. This velocity should be kept less than 120% of sonic velocity. It is directly proportional to explosive type and its density.

- 7. ï Principle of Explosion âĒ This welding process works on basic principle of metallurgical bonding. âĒ In this process, a controlled detonation of explosive is used on the welding surface. âĒ flyer metal can be placed parallel or inclined to the base plate âĒ Explosive material is distributed over top of cladder metal âĒ Upon detonation, cladder plate collides with base plate to form weld

- 8. ï OBLIQUE EXPLOSION WELDING ï§ In this type of welding process base plate is fixed on an anvil. ï§ Flyer plate makes an angle with the base plate. ï§ This welding configuration is used to join thin and small plates.

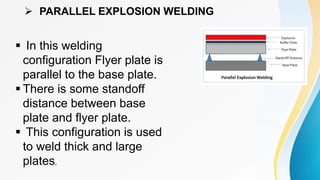

- 9. ï PARALLEL EXPLOSION WELDING ï§ In this welding configuration Flyer plate is parallel to the base plate. ï§ There is some standoff distance between base plate and flyer plate. ï§ This configuration is used to weld thick and large plates.

- 10. CONTD. Where: Vc = collision velocity VD = detonation velocity Vp = plate Collision velocity Îą = preset angle Îē = dynamic bend

- 11. WORKING: ï§ Both the base and the flyer plate is cleaned. ï§ The base plate fixed on the anvil ï§ The flyer plate may be inclined or parallel according to the welding configuration. ï§ Now the detonator ignited the explosive which create a high pressure wave. ï§ These waves deforms the interface surface plastically and form a metallurgical bond between base plate and flyer plate. ï§ This bond is stronger than parent material.

- 12. ï Explosive material âĒ High velocity (14750-25000 ft/s) â Trinitrotoluene (TNT) â Cyclotrimethylenetrinitramine (RDX) â Pentaerythritol Tetranitrate (PETN) âĒ Mid-low velocity (4900-47500 ft/s) â Ammonium nitrate â Ammonium perchlorate â Amatol

- 13. ï Assuring a good weld Detonation velocity is a function of â Explosive type â Composition of explosive â Thickness of explosive layer

- 14. ï Assuring a good weld: âĒ Sonic velocity of cladding material can calculated using: Where:- K = adiabatic bulk modulus Ï = cladding material density E = Youngâs Modulus of cladding material âŦŨĒ⎠= Poissonâs ratio of cladding material

- 15. ADVANTAGES: ï§ It can join both similar and dissimilar material. ï§ Simple in operation and handling. ï§ Large surface can be weld in single pass. ï§ High metal joining rate. Mostly time is used in preparation of the welding. ï§ It does not effect on properties of welding material. ï§ It is solid state process so does not involve any filler material, flux etc.

- 16. DISADVANTAGES: ï§ It can weld only ductile metal with high toughness. ï§ It creates a large noise which produces noise Pollution. ï§ Welding is highly depends on process parameters. ï§ Higher safety precautions involved due to explosive. ï§ Designs of joints are limited.

- 17. Applications: âĒ Used to weld large structure sheets of aluminium to stainless steel. âĒ It is used to weld cylindrical component like pipe, concentric cylinder, tube etc. âĒ Join dissimilar metals which cannot be weld by other welding process. âĒ For joining cooling fan etc.

- 18. Common industries that use explosion welding âĒ Chemical Processing âĒ Petroleum Refining âĒ Hydrometallurgy âĒ Aluminum Smelting âĒ Shipbuilding âĒ Electrochemical âĒ Oil & Gas âĒ Power Generation âĒ Cryogenic Processing âĒ Pulp & Paper âĒ Air conditioning & Chillers

- 19. Examples

- 20. References: âĒ http://www.awssection.org/uploads/longbeach/files/wj0706 -38.pdf. âĒ J.Verstraete,W.De Waele and K.faes :lesson to be learned from explosive welding 2011. âĒ Wikipedia.

- 21. THANK YOU