114-3 drills bits fixings

- 1. 1 Level 1 Diploma in Carpentry and Joinery PowerPointpresentation Drills, Bits & Fixings Unit 114: Prepare and use carpentry and joinery Portable Power Tools

- 2. 2 Level 1 Diploma in Carpentry and Joinery Objectives To be able to: 3.1 State types and uses of portable power drills 3.2 State the different types and sizes of screwdriver bits 3.3 State the different types of drill bits 3.4 Identify suitable fixings for different materials and surfaces 3.5 State methods used to locate services prior to carrying out the drilling operation

- 3. 3 Level 1 Diploma in Carpentry and Joinery Also known as the combi drill. It can be used for a variety of tasks: • Low speeds for hi-torque screw driving. • Higher speeds for drilling wood or metal. • Hammer function adds percussive "blows" for light duty drilling into masonry. • Reverse for screw removal. • Keyless chuck. • Available corded and cordless. Drill Drivers

- 4. 4 Level 1 Diploma in Carpentry and Joinery • Specially engineered to do one job: drive screws, which it does faster, easier and better than a drill driver. • Uses both bit rotation and concussive blows to power-drive screws through the thickest, densest hardwoods. • Two to three times more turning power (torque) than the average drill driver: it can drive long, large fasteners through wet timber all day long. • Instead of a chuck, it has a locking collet that accepts hex-shanked driver bits only. Impact Drivers

- 5. 5 Level 1 Diploma in Carpentry and Joinery • The hammer drill uses round shank twist drill bits, and is used for drilling into different materials such as stone, masonry, wood and metal. • Has a percussive hammer action for boring into brickwork, blockwork and stone. • Not suitable for drilling into concrete. Percussion (Hammer) Drills Masonry (Hammer) bit

- 6. 6 Level 1 Diploma in Carpentry and Joinery • Special Direct System rotary hammer drills are the only portable power drills capable of the heaviest work (into concrete). • Has a special shank-locking system so the bit is powered directly by the drill and is kept from slipping. • The rotary/hammer action can be switched to hammer only so it can be used as a masonry chisel for chasing walls. SDS Drills

- 7. 7 Level 1 Diploma in Carpentry and Joinery • Time-saving tool used when a large volume of screws need to be repeatedly driven over extended periods. • Screws are supplied on a plastic belt or reel and fed into the drill. • Available corded and cordless. Auto-feed screwdriver

- 8. 8 Level 1 Diploma in Carpentry and Joinery Types and Sizes of Screwdriver Bits Pozi-drivePhillips Slotted

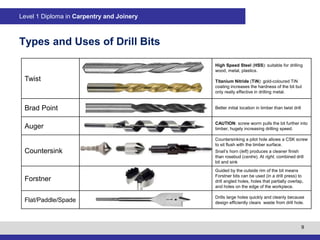

- 9. 9 Level 1 Diploma in Carpentry and Joinery Twist High Speed Steel (HSS): suitable for drilling wood, metal, plastics. Titanium Nitride (TiN): gold-coloured TiN coating increases the hardness of the bit but only really effective in drilling metal. Brad Point Better initial location in timber than twist drill Auger CAUTION: screw worm pulls the bit further into timber, hugely increasing drilling speed. Countersink Countersinking a pilot hole allows a CSK screw to sit flush with the timber surface. Snail’s horn (left) produces a cleaner finish than rosebud (centre). At right, combined drill bit and sink Forstner Guided by the outside rim of the bit means Forstner bits can be used (in a drill press) to drill angled holes, holes that partially overlap, and holes on the edge of the workpiece. Flat/Paddle/Spade Drills large holes quickly and cleanly because design efficiently clears waste from drill hole. Types and Uses of Drill Bits

- 10. 10 Level 1 Diploma in Carpentry and Joinery (Rawl) Plastic Plugs For fixing into brickwork, blockwork and stone. Hammer-in (Nailable) Plugs Hollow Wall Anchor Cavity Fixings: For fixing into thin or hollow walls (plasterboard) Spring Toggle Metal Self-Drill Plasterboard Plugs Fixings for Different Materials and Surfaces

- 11. 11 Level 1 Diploma in Carpentry and Joinery Round Wire Nail Masonry Nail Dry wall screw (into plasterboard) Pozidriv Wood Screw Cut Nail Oval Brad Annular Ring Nail Self-cutting screw (into sheet metal) Nails & Screws

- 12. 12 Level 1 Diploma in Carpentry and Joinery Kitchen Fitters’ Cabinet Spacers

- 13. 13 Level 1 Diploma in Carpentry and Joinery Methods used to locate services When drilling into walls, floors and ceilings, site workers must avoid services to the building: • Electric cables • Gas pipes • Fresh water pipes • Black water pipes • Telecommunications cables Building Regulations require that services must be carefully located at set depths, heights and positions in buildings (eg vertical cabling from a socket). HOWEVER, this is not always complied with. So, prior to work, tradesmen must always use a digital detector to locate and avoid buried services and identify stud work that can be drilled or nailed into.