Types of coupling

- 2. Content • What is coupling? • Types of Coupling 1)Rigid Coupling (A)Sleeve or Muff Coupling (B)Clamp or Split muff or compression coupling (C)Flange Coupling <1> Unprotected Type <2> Protected Type

- 3. 2)Flexible Coupling (A)Bushed pin type flange coupling (B)Universal Coupling (C)Oldham’s Coupling

- 5. What is coupling? • A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power.

- 6. • It is used to connect two shafts which are perfectly in axial alignment. These couplings do not allow any relative rotation between the two shafts.

- 7. Types of Rigid coupling 1)Sleeve or Muff Coupling 2)Clamp or Split Muff or Compression Coupling 3)Flange Coupling (a) Unprotected type (b) Protected type

- 8. Sleeve or Muff Coupling • This is the simplest form of rigid coupling. It is made up of cast iron and very simple to design and manufacture. It consists of hollow cylinder(muff) whose inner diameter is same as diameter of shaft as shown in figure.

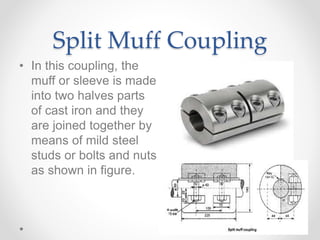

- 9. Split Muff Coupling • In this coupling, the muff or sleeve is made into two halves parts of cast iron and they are joined together by means of mild steel studs or bolts and nuts as shown in figure.

- 10. Flange Coupling 1) Unprotected Type Flange Coupling: This coupling is having two separate cast iron flanges as shown in figure an unprotected type flange coupling. Each flange is mounted on the shafts end and keyed to it. The two flanges are coupled together by help of bolts and nuts.

- 11. The projected portion of one of the flange and corresponding recess on other flange are help to bring the shafts into line and maintain alignment

- 12. 2) Protected type flange coupling: a flange is provided with shroud which shelters the bolt heads and nuts as shown in figure is called protected type flange coupling. This coupling prevents catching clothes of workman.

- 13. • This coupling is used to protect the driving and driven machine members against harmful effects produce due to misalignment of shafts, vibration, sudden shock load or shaft expansion.

- 14. Types of Flexible Coupling 1)Bush pin type flange coupling 2)Oldham’s coupling 3)Universal coupling or Hooke’s joint

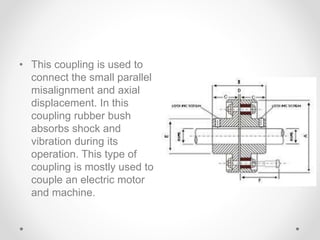

- 15. Bush Pin Type Coupling • This is the modified form of flange coupling. This type f coupling has a pins and it work as a coupling bolts. The rubber or leather bushes are used over the pins. The coupling is having two halves are dissimilar in construction as shown in figure. The pins are rigidly fastened by nuts to one of the flange and kept loose in the other flange.

- 16. • This coupling is used to connect the small parallel misalignment and axial displacement. In this coupling rubber bush absorbs shock and vibration during its operation. This type of coupling is mostly used to couple an electric motor and machine.

- 17. Oldham’s Coupling • It consists of two flanges with slots and a central floating disc as shown in figure. The disc having two tongues at right angles. The one tongue is fitted into the slot of first flange and allows horizontal sliding relative motion with the other tongue is fitted into the slot of the second flange and allows for vertical sliding relative motion.

- 18. • This right angle motions of tongues on the slots will accommodate lateral misalignment of shafts when they rotate. • Oldham’s coupling is used in connecting two parallel shafts but not in alignment, and their axis are at small distance apart.

- 19. Universal Coupling • Universal coupling consists of two similar forks keyed on the ends of the two shafts as shown in the figure. These two forks are assembled to a central block by pin. A central block having two arms at right angle to each other. Universal coupling is used to connect two shafts whose axis intersect.

- 20. • Universal coupling is also used to connect two shafts, where the angle between two shaft may be varied when they rotate. The universal coupling is widely used in automobile and machine tools.

- 21. References ElementsOf Mechanical Engineering By- H. G. Katariya J. P. Hadiya S. M. Bhatt Books IndiaPublications

- 22. Prepared By Shethpreetsanketkumar M. E. 3, batch - c 170050119548