UNIT- IV --HEAT TREATMENT.pptx

Download as pptx, pdf0 likes49 views

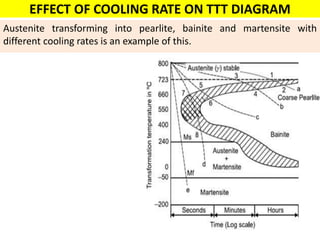

The document outlines various heat treatment processes for steel, such as annealing, normalizing, hardening, and tempering, each with distinct techniques and purposes. It discusses the effects of temperature, time, and cooling rates on the mechanical properties of steel, alongside the significance of TTT and CCT diagrams in understanding phase transformations. Different annealing types and their applications, including full and stress relief annealing, are also described to illustrate the treatment's objectives in modifying material properties.

1 of 22

Download to read offline

Ad

Recommended

HEAT TREATMENT

HEAT TREATMENTMuthukumar V

╠²

Heat treatment involves heating and cooling of metals to obtain desired properties. Common heat treatment processes include annealing, normalizing, and hardening. Quenching involves rapidly cooling heated steel to make it harder and stronger. Case hardening processes like carburizing add carbon to the surface of low-carbon steel to create a hard outer case. Induction and flame hardening are surface hardening techniques used for gears, shafts and other rotating components. Time-temperature transformation and continuous cooling transformation diagrams are used to determine the microstructures that form during heat treating processes.UNIT- IV.pptx

UNIT- IV.pptxMuthukumar P

╠²

The document provides an extensive overview of various heat treatment processes for metals, particularly focusing on steel. It details operations like annealing, quenching, and normalizing, along with specific processes such as carburizing and nitriding for case hardening. Additionally, it discusses the importance of cooling rates, hardenability, and the effects of heat treatment on the mechanical properties of steel.EM-Unit-IV- heat treatment

EM-Unit-IV- heat treatmentMohanumar S

╠²

The document discusses heat treatment processes used to alter the properties of metals and alloys. It describes various heat treatment methods like annealing, normalizing, hardening, and tempering. Annealing is used to relieve stress, induce softness, refine grain size, and remove gases. Normalizing involves heating above the critical temperature and air cooling to refine grain size and relieve stress. Hardening involves heating and quenching to produce martensite for hardness. Tempering is used after hardening to reduce brittleness by reheating and slow cooling. The document provides details on the purposes, procedures, and applications of different heat treatment techniques.1 heat treatment

1 heat treatmentMathankumarA5

╠²

The document discusses various heat treatment processes used to alter the properties of metals and alloys. It describes processes like annealing, normalizing, hardening, and tempering. Annealing is used to relieve stress, soften metals, and refine grain size. Normalizing produces a uniform structure and relieves stresses. Hardening involves heating metal and rapidly cooling to produce martensite for hardness. Tempering is then used to reduce brittleness caused by hardening. The document also discusses diagrams like TTT and CCT that are used to determine the effects of different cooling rates on microstructure formation. heat treatment

heat treatmentMohanKirthik

╠²

The document discusses various heat treatment processes used to alter the properties of metals and alloys. It describes processes like annealing, normalizing, hardening, and tempering. Annealing is used to relieve stress, soften metals, and refine grain size. Normalizing produces a uniform structure and relieves stresses. Hardening involves heating metal and rapidly cooling to produce martensite for hardness. Tempering is then used to reduce brittleness caused by hardening. The document also discusses diagrams like TTT and CCT that are used to determine the effects of different cooling rates on microstructure formation.Heat Treatment

Heat TreatmentMuthukumar V

╠²

The document discusses various heat treatment processes used to alter the properties of metals and alloys. It describes processes like annealing, normalizing, hardening, and tempering. Annealing is used to relieve stress and induce softness. Normalizing increases strength and achieves a uniform structure. Hardening through quenching improves hardness but causes brittleness, which tempering relieves by controlled reheating. The Jominy end quench test measures a steel's hardenability or ability to harden uniformly during quenching.1 heat treatment

1 heat treatmentChandra Kumar S

╠²

The document discusses various heat treatment processes used to alter the properties of metals and alloys. It describes the basic stages of heat treatment which involve heating metals to specific temperatures, holding for a period of time, and then cooling. Several heat treatment processes are defined, including annealing, normalizing, hardening, and tempering. Time-temperature-transformation diagrams and continuous cooling transformation diagrams are also introduced to illustrate how different cooling rates affect the microstructures that form in steels.heat treatment

heat treatmentPraveenManickam2

╠²

The document discusses various heat treatment processes used to alter the properties of metals and alloys. It describes the basic stages of heat treatment which involve heating metal to specific temperatures, holding for a period of time, and then cooling. Several heat treatment processes are then outlined, including annealing, normalizing, hardening, and tempering. Diagrams like the TTT diagram and CCT diagram are also introduced to illustrate how different cooling rates affect the microstructure and properties of steels.TTT diagram and Heat treatment processes

TTT diagram and Heat treatment processesSaumy Agarwal

╠²

The document discusses TTT (time-temperature-transformation) diagrams and heat treatment processes. It explains that TTT diagrams show the structures that form after various cooling rates from the austenite phase. The diagrams graphically depict the cooling rates required to form pearlite, bainite, or martensite. Common heat treatments include annealing, normalizing, quenching, and tempering. Annealing relieves stresses and improves ductility while normalizing produces a more uniform grain structure. Quenching followed by tempering increases hardness but reduces brittleness. Surface hardening techniques like carburizing and nitriding introduce carbon or nitrogen to harden the surface.heat treatment course for engineers .pdf

heat treatment course for engineers .pdfZiad Salem

╠²

The document outlines the principles and processes of heat treatment in metallurgy, covering various techniques such as annealing, normalizing, and hardening. It explains the effects of these treatments on the properties of metals, including modifications to microstructure and mechanical characteristics. Additionally, it highlights the significance of temperature and cooling rates in achieving desired material properties and emphasizes practical applications in industrial contexts.Heat treatment of steel

Heat treatment of steelmeet patel

╠²

The document provides information on heat treatment processes for steel, including:

- TTT diagrams show the relationship between temperature and time for decomposition transformations under isothermal conditions.

- Construction of TTT diagrams involves isothermally heating and quenching many small steel specimens to determine reaction curves.

- Common heat treatments include annealing, normalizing, hardening and tempering. Annealing relieves stresses while normalizing refines grains. Hardening forms martensite to increase hardness but tempering is required afterwards to improve properties.Heat treatment

Heat treatmentDJAGADEESH1

╠²

The document discusses heat treatment processes for metals like steel. It describes the purposes of heat treatment as relieving stress, improving machinability, and changing grain structure. Specific heat treatment processes covered include annealing, normalizing, hardening, and tempering. Annealing involves slowly heating and cooling to soften metals. Normalizing heats above critical temperature and air cools for hardness. Hardening rapidly cools from above critical temperature to form martensite for maximum hardness. Tempering then reheats hardened steel to relieve brittleness.heat treatment unit 3 M4.pptx

heat treatment unit 3 M4.pptxRitikBasotra

╠²

The document discusses heat treatment processes including annealing, normalizing, hardening, tempering, and quenching. Annealing involves heating material to relieve stresses and improve ductility. Normalizing is similar but involves faster cooling in air to refine grain structure. Hardening rapidly cools steel from an austenitizing temperature to form martensite for high hardness. Tempering reheats hardened steel to improve toughness by forming ferrite and fine cementite. Quenching rapidly cools materials for microstructural changes like martensite formation in steel.17767705 heat-treatment-oct08

17767705 heat-treatment-oct08moh481989

╠²

Heat treatment involves controlled heating and cooling of materials to alter their structure and properties. Some key points:

1. Heat treatment includes processes like annealing, normalizing, hardening, and case hardening.

2. Annealing refines grain structure and improves ductility and machinability. Normalizing refines grain size uniformly.

3. Phase diagrams and TTT/CCT diagrams are used to determine appropriate heating temperatures and cooling rates to achieve desired microstructures and properties. Heat treatment lecture notes pages-135-170-converted

Heat treatment lecture notes pages-135-170-convertedYashvir Singh

╠²

The document discusses various heat treatment processes for materials including annealing, normalizing, hardening, and tempering. Annealing involves heating steel above or below certain critical temperatures followed by slow cooling to modify properties like hardness and ductility. Normalizing also involves heating above critical temperatures but with faster cooling to produce finer pearlite. Hardening greatly increases hardness through quenching but results in brittleness, so tempering is used to restore toughness through controlled reheating. The document provides details on the purposes, methods, and effects of various heat treatment processes.heat tratment & iron carbon diagram

heat tratment & iron carbon diagrammukeshkumar2062

╠²

The document discusses the iron-iron carbide diagram and heat treatment processes for steels. It provides details on the phases in the Fe-C diagram including ferrite, cementite, austenite, and pearlite. It also summarizes common heat treatments like full annealing, normalizing, hardening, and tempering. Full annealing involves heating above A3 and furnace cooling to form coarse pearlite for high ductility. Normalizing involves heating above A3 and air cooling to form fine pearlite for improved hardness and ductility. Hardening involves heating above A3 and quenching to form martensite for high strength but brittleness, followed by tempering to improve toughness.Heat Treatments Material Technology.pptx

Heat Treatments Material Technology.pptxDivyaPrakashSingh21

╠²

This document provides an introduction to heat treatment processes. It discusses how heat treatments involve controlled heating and cooling of metals to alter their physical and mechanical properties without changing shape. The major types of heat treatments covered are annealing, normalizing, hardening, carburizing, and tempering. Hardening specifically involves rapidly cooling steel to form martensite, making it very hard but brittle. Tempering is then used to relieve stresses and improve ductility by decomposing martensite. Other processes like martempering and austempering form alternative microstructures to martensite. The document provides details on the purposes, mechanisms, and effects of various heat treatment techniques.Heat Treatments

Heat TreatmentsJose Surendran

╠²

This document provides information on various heat treatment processes for steel, including annealing, normalizing, hardening, and tempering. It describes the purposes and procedures for each process. Key points include:

- Annealing involves heating steel above the upper critical temperature, then slow cooling to relieve stresses and improve ductility.

- Normalizing also involves heating above the upper critical temperature, but the steel is air cooled to refine grain size while retaining some strength.

- Hardening greatly increases strength by heating steel to the austenitizing temperature then quenching in water or oil to form martensite.

- Tempering is then used to reduce brittleness by reheating hardened steel to lower temperatures.Heat treatment 1

Heat treatment 1senthamarai kannan

╠²

The document provides an overview of heat treatment processes in metallurgy, explaining how controlled heating and cooling affect the properties of metals like toughness, hardness, and ductility. It details various heat treatment methods, including annealing, hardening, and tempering, along with their specific temperature ranges and microstructural transformations. Additionally, it discusses the importance of processes like normalizing and stress relief in enhancing the machinability and overall performance of steel alloys.Unit 4.ppt

Unit 4.pptAbhishekChavan77

╠²

This document discusses heat treatment processes for steels, including annealing, normalizing, hardening, tempering, and surface hardening treatments. It defines each process, explains their objectives and effects on microstructure and properties, and compares the differences between annealing and normalizing. Key points covered include how each treatment alters the steel's microstructure, hardness, strength, and other mechanical properties through controlled heating and cooling operations.Materials and Metallurgy Heat treatment

Materials and Metallurgy Heat treatmentMushahid Khan Yusufzai

╠²

The document provides information about heat treatment processes for steels. It discusses various heat treatment types including softening treatments like annealing and normalizing, hardening treatments, and other processes like cyclic annealing, isothermal annealing, diffusion annealing, and sub-zero treatment. The objectives, processes, microstructure changes, advantages and applications are explained for each heat treatment type. Defects associated with hardening like steel being too soft, irregularly hard, distorted, and cracked are also outlined.Heat treatment

Heat treatment knowledge

╠²

This document discusses various heat treatments that can be used on steels, including:

- Annealing treatments like full annealing, recrystallization annealing, stress relief annealing, and spheroidization annealing.

- Normalizing to refine grain structure, harden slightly, and reduce segregation.

- Hardening by heating above the transformation temperatures and quenching to form martensite, followed by tempering.

- Factors that influence the severity of quenching and hardenability of steels, such as the quenching medium, agitation level, and alloying elements. Microstructures can vary from surface to interior based on cooling rate.02 heat treatment

02 heat treatmentDevendra Hembade

╠²

The document provides information about heat treatment processes. It defines heat treatment as a process of heating and cooling metals and alloys in the solid state to change their properties. Heat treatment is done to change properties like strength, hardness, toughness etc. of steels. The key heat treatment processes described are annealing, normalizing, hardening and tempering. Annealing involves heating steel above or below its critical temperature, holding, and slow cooling to soften it and relieve stresses. The goals, processes, and effects of various annealing types like full annealing and spheroidizing annealing are explained.Ch 27.3 heat treatment of metals

Ch 27.3 heat treatment of metalsNandan Choudhary

╠²

Heat treatment involves heating metals or alloys to specific temperatures, holding for durations, and cooling at controlled rates. This controls microstructure and properties. Key processes include annealing, stress relieving, hardening, tempering, and carburizing. Annealing relieves stresses and strains, improves machinability and ductility. Normalizing refines grains and relieves stresses. Stress relieving reduces stresses without changing microstructure.Heat treatment 1 dr.sss1

Heat treatment 1 dr.sss1saravana kumar

╠²

Heat treatment involves controlled heating and cooling of metals to change their properties through modifying microstructure and chemistry. It is used to improve properties like hardness, toughness, ductility, and wear resistance. Common heat treatments include annealing, normalizing, hardening, and tempering. Annealing produces a soft microstructure for ductility, while normalizing produces a finer grain structure. Hardening involves quenching after heating to form martensite for hardness, followed by tempering to relieve brittleness. Alloying can increase hardenability to allow deeper hardening of parts.Heat Treatment Process

Heat Treatment ProcessVikas Barnwal

╠²

The document discusses various heat treatment processes including annealing, normalizing, hardening, tempering, and analyzing hardenability. Annealing involves heating material to relieve stresses and improve ductility. Normalizing is similar but involves faster cooling in air to refine grain structure. Hardening increases hardness through rapid quenching from austenitizing temperatures resulting in martensite formation. Tempering improves toughness of hardened steel by reheating to precipitate carbides. Hardenability is measured using the Jominy end quench test and indicates the depth of hardness achieved during quenching.Module 3.ppt

Module 3.pptSahalSachu

╠²

This document discusses various heat treatment processes and methods for strengthening metals. It describes annealing, normalizing, hardening, tempering, and other heat treatment ranges and their purposes. It also explains different mechanisms for strengthening metals, including strain hardening, grain boundary strengthening, solid solution strengthening, and dispersion strengthening. The key factors that influence heat treatability and various surface hardening techniques are outlined as well.UNIT- V ---TESTING OF MECHANICAL PROPERTIES.pptx

UNIT- V ---TESTING OF MECHANICAL PROPERTIES.pptxShanmathyAR2

╠²

The document discusses various mechanical properties and tests used to evaluate them. It describes the different types of strength materials can exhibit including elastic strength and plastic strength. Factors that can influence mechanical properties are then outlined such as grain size, heat treatment, and temperature. Common deformation mechanisms like slip and twinning are also defined. Different types of mechanical tests are classified as either destructive or non-destructive and specific tests are detailed including hardness, impact, fatigue, compression, and creep tests.UNIT - II --FERROUS AND NON FERROUS ALLOYS.pptx

UNIT - II --FERROUS AND NON FERROUS ALLOYS.pptxShanmathyAR2

╠²

The document discusses ferrous and non-ferrous alloys, including the classification and properties of various steels such as low, medium, and high carbon steels, as well as alloy and stainless steels. It also covers non-ferrous materials like copper, brass, bronzes, silver, and gold, highlighting their applications and properties. Additionally, it outlines precipitation hardening treatment used to enhance the physical properties of non-ferrous alloys through specific heat treatment processes.More Related Content

Similar to UNIT- IV --HEAT TREATMENT.pptx (20)

TTT diagram and Heat treatment processes

TTT diagram and Heat treatment processesSaumy Agarwal

╠²

The document discusses TTT (time-temperature-transformation) diagrams and heat treatment processes. It explains that TTT diagrams show the structures that form after various cooling rates from the austenite phase. The diagrams graphically depict the cooling rates required to form pearlite, bainite, or martensite. Common heat treatments include annealing, normalizing, quenching, and tempering. Annealing relieves stresses and improves ductility while normalizing produces a more uniform grain structure. Quenching followed by tempering increases hardness but reduces brittleness. Surface hardening techniques like carburizing and nitriding introduce carbon or nitrogen to harden the surface.heat treatment course for engineers .pdf

heat treatment course for engineers .pdfZiad Salem

╠²

The document outlines the principles and processes of heat treatment in metallurgy, covering various techniques such as annealing, normalizing, and hardening. It explains the effects of these treatments on the properties of metals, including modifications to microstructure and mechanical characteristics. Additionally, it highlights the significance of temperature and cooling rates in achieving desired material properties and emphasizes practical applications in industrial contexts.Heat treatment of steel

Heat treatment of steelmeet patel

╠²

The document provides information on heat treatment processes for steel, including:

- TTT diagrams show the relationship between temperature and time for decomposition transformations under isothermal conditions.

- Construction of TTT diagrams involves isothermally heating and quenching many small steel specimens to determine reaction curves.

- Common heat treatments include annealing, normalizing, hardening and tempering. Annealing relieves stresses while normalizing refines grains. Hardening forms martensite to increase hardness but tempering is required afterwards to improve properties.Heat treatment

Heat treatmentDJAGADEESH1

╠²

The document discusses heat treatment processes for metals like steel. It describes the purposes of heat treatment as relieving stress, improving machinability, and changing grain structure. Specific heat treatment processes covered include annealing, normalizing, hardening, and tempering. Annealing involves slowly heating and cooling to soften metals. Normalizing heats above critical temperature and air cools for hardness. Hardening rapidly cools from above critical temperature to form martensite for maximum hardness. Tempering then reheats hardened steel to relieve brittleness.heat treatment unit 3 M4.pptx

heat treatment unit 3 M4.pptxRitikBasotra

╠²

The document discusses heat treatment processes including annealing, normalizing, hardening, tempering, and quenching. Annealing involves heating material to relieve stresses and improve ductility. Normalizing is similar but involves faster cooling in air to refine grain structure. Hardening rapidly cools steel from an austenitizing temperature to form martensite for high hardness. Tempering reheats hardened steel to improve toughness by forming ferrite and fine cementite. Quenching rapidly cools materials for microstructural changes like martensite formation in steel.17767705 heat-treatment-oct08

17767705 heat-treatment-oct08moh481989

╠²

Heat treatment involves controlled heating and cooling of materials to alter their structure and properties. Some key points:

1. Heat treatment includes processes like annealing, normalizing, hardening, and case hardening.

2. Annealing refines grain structure and improves ductility and machinability. Normalizing refines grain size uniformly.

3. Phase diagrams and TTT/CCT diagrams are used to determine appropriate heating temperatures and cooling rates to achieve desired microstructures and properties. Heat treatment lecture notes pages-135-170-converted

Heat treatment lecture notes pages-135-170-convertedYashvir Singh

╠²

The document discusses various heat treatment processes for materials including annealing, normalizing, hardening, and tempering. Annealing involves heating steel above or below certain critical temperatures followed by slow cooling to modify properties like hardness and ductility. Normalizing also involves heating above critical temperatures but with faster cooling to produce finer pearlite. Hardening greatly increases hardness through quenching but results in brittleness, so tempering is used to restore toughness through controlled reheating. The document provides details on the purposes, methods, and effects of various heat treatment processes.heat tratment & iron carbon diagram

heat tratment & iron carbon diagrammukeshkumar2062

╠²

The document discusses the iron-iron carbide diagram and heat treatment processes for steels. It provides details on the phases in the Fe-C diagram including ferrite, cementite, austenite, and pearlite. It also summarizes common heat treatments like full annealing, normalizing, hardening, and tempering. Full annealing involves heating above A3 and furnace cooling to form coarse pearlite for high ductility. Normalizing involves heating above A3 and air cooling to form fine pearlite for improved hardness and ductility. Hardening involves heating above A3 and quenching to form martensite for high strength but brittleness, followed by tempering to improve toughness.Heat Treatments Material Technology.pptx

Heat Treatments Material Technology.pptxDivyaPrakashSingh21

╠²

This document provides an introduction to heat treatment processes. It discusses how heat treatments involve controlled heating and cooling of metals to alter their physical and mechanical properties without changing shape. The major types of heat treatments covered are annealing, normalizing, hardening, carburizing, and tempering. Hardening specifically involves rapidly cooling steel to form martensite, making it very hard but brittle. Tempering is then used to relieve stresses and improve ductility by decomposing martensite. Other processes like martempering and austempering form alternative microstructures to martensite. The document provides details on the purposes, mechanisms, and effects of various heat treatment techniques.Heat Treatments

Heat TreatmentsJose Surendran

╠²

This document provides information on various heat treatment processes for steel, including annealing, normalizing, hardening, and tempering. It describes the purposes and procedures for each process. Key points include:

- Annealing involves heating steel above the upper critical temperature, then slow cooling to relieve stresses and improve ductility.

- Normalizing also involves heating above the upper critical temperature, but the steel is air cooled to refine grain size while retaining some strength.

- Hardening greatly increases strength by heating steel to the austenitizing temperature then quenching in water or oil to form martensite.

- Tempering is then used to reduce brittleness by reheating hardened steel to lower temperatures.Heat treatment 1

Heat treatment 1senthamarai kannan

╠²

The document provides an overview of heat treatment processes in metallurgy, explaining how controlled heating and cooling affect the properties of metals like toughness, hardness, and ductility. It details various heat treatment methods, including annealing, hardening, and tempering, along with their specific temperature ranges and microstructural transformations. Additionally, it discusses the importance of processes like normalizing and stress relief in enhancing the machinability and overall performance of steel alloys.Unit 4.ppt

Unit 4.pptAbhishekChavan77

╠²

This document discusses heat treatment processes for steels, including annealing, normalizing, hardening, tempering, and surface hardening treatments. It defines each process, explains their objectives and effects on microstructure and properties, and compares the differences between annealing and normalizing. Key points covered include how each treatment alters the steel's microstructure, hardness, strength, and other mechanical properties through controlled heating and cooling operations.Materials and Metallurgy Heat treatment

Materials and Metallurgy Heat treatmentMushahid Khan Yusufzai

╠²

The document provides information about heat treatment processes for steels. It discusses various heat treatment types including softening treatments like annealing and normalizing, hardening treatments, and other processes like cyclic annealing, isothermal annealing, diffusion annealing, and sub-zero treatment. The objectives, processes, microstructure changes, advantages and applications are explained for each heat treatment type. Defects associated with hardening like steel being too soft, irregularly hard, distorted, and cracked are also outlined.Heat treatment

Heat treatment knowledge

╠²

This document discusses various heat treatments that can be used on steels, including:

- Annealing treatments like full annealing, recrystallization annealing, stress relief annealing, and spheroidization annealing.

- Normalizing to refine grain structure, harden slightly, and reduce segregation.

- Hardening by heating above the transformation temperatures and quenching to form martensite, followed by tempering.

- Factors that influence the severity of quenching and hardenability of steels, such as the quenching medium, agitation level, and alloying elements. Microstructures can vary from surface to interior based on cooling rate.02 heat treatment

02 heat treatmentDevendra Hembade

╠²

The document provides information about heat treatment processes. It defines heat treatment as a process of heating and cooling metals and alloys in the solid state to change their properties. Heat treatment is done to change properties like strength, hardness, toughness etc. of steels. The key heat treatment processes described are annealing, normalizing, hardening and tempering. Annealing involves heating steel above or below its critical temperature, holding, and slow cooling to soften it and relieve stresses. The goals, processes, and effects of various annealing types like full annealing and spheroidizing annealing are explained.Ch 27.3 heat treatment of metals

Ch 27.3 heat treatment of metalsNandan Choudhary

╠²

Heat treatment involves heating metals or alloys to specific temperatures, holding for durations, and cooling at controlled rates. This controls microstructure and properties. Key processes include annealing, stress relieving, hardening, tempering, and carburizing. Annealing relieves stresses and strains, improves machinability and ductility. Normalizing refines grains and relieves stresses. Stress relieving reduces stresses without changing microstructure.Heat treatment 1 dr.sss1

Heat treatment 1 dr.sss1saravana kumar

╠²

Heat treatment involves controlled heating and cooling of metals to change their properties through modifying microstructure and chemistry. It is used to improve properties like hardness, toughness, ductility, and wear resistance. Common heat treatments include annealing, normalizing, hardening, and tempering. Annealing produces a soft microstructure for ductility, while normalizing produces a finer grain structure. Hardening involves quenching after heating to form martensite for hardness, followed by tempering to relieve brittleness. Alloying can increase hardenability to allow deeper hardening of parts.Heat Treatment Process

Heat Treatment ProcessVikas Barnwal

╠²

The document discusses various heat treatment processes including annealing, normalizing, hardening, tempering, and analyzing hardenability. Annealing involves heating material to relieve stresses and improve ductility. Normalizing is similar but involves faster cooling in air to refine grain structure. Hardening increases hardness through rapid quenching from austenitizing temperatures resulting in martensite formation. Tempering improves toughness of hardened steel by reheating to precipitate carbides. Hardenability is measured using the Jominy end quench test and indicates the depth of hardness achieved during quenching.Module 3.ppt

Module 3.pptSahalSachu

╠²

This document discusses various heat treatment processes and methods for strengthening metals. It describes annealing, normalizing, hardening, tempering, and other heat treatment ranges and their purposes. It also explains different mechanisms for strengthening metals, including strain hardening, grain boundary strengthening, solid solution strengthening, and dispersion strengthening. The key factors that influence heat treatability and various surface hardening techniques are outlined as well.More from ShanmathyAR2 (14)

UNIT- V ---TESTING OF MECHANICAL PROPERTIES.pptx

UNIT- V ---TESTING OF MECHANICAL PROPERTIES.pptxShanmathyAR2

╠²

The document discusses various mechanical properties and tests used to evaluate them. It describes the different types of strength materials can exhibit including elastic strength and plastic strength. Factors that can influence mechanical properties are then outlined such as grain size, heat treatment, and temperature. Common deformation mechanisms like slip and twinning are also defined. Different types of mechanical tests are classified as either destructive or non-destructive and specific tests are detailed including hardness, impact, fatigue, compression, and creep tests.UNIT - II --FERROUS AND NON FERROUS ALLOYS.pptx

UNIT - II --FERROUS AND NON FERROUS ALLOYS.pptxShanmathyAR2

╠²

The document discusses ferrous and non-ferrous alloys, including the classification and properties of various steels such as low, medium, and high carbon steels, as well as alloy and stainless steels. It also covers non-ferrous materials like copper, brass, bronzes, silver, and gold, highlighting their applications and properties. Additionally, it outlines precipitation hardening treatment used to enhance the physical properties of non-ferrous alloys through specific heat treatment processes.UNIT - I ---CONSTITUTION OF ALLOYS.pptx

UNIT - I ---CONSTITUTION OF ALLOYS.pptxShanmathyAR2

╠²

The document discusses the constitution of alloys in engineering metallurgy, explaining that alloys are composed of two or more materials to enhance properties such as strength. It covers solid solutions, their types (substitutional and interstitial), the cooling curves relevant to pure metals and binary alloys, and introduces Gibbs phase rule for understanding system states. Additionally, it describes various reactions in the iron-carbon system, classification of phase diagrams, and differences between hypoeutectoid and hypereutectoid steels and cast iron based on carbon content.UNIT- III ---NON-METALLIC MATERIALS.pptx

UNIT- III ---NON-METALLIC MATERIALS.pptxShanmathyAR2

╠²

The document provides an overview of non-metallic materials, focusing on various types of polymers, their properties, structures, and applications. It highlights key polymers such as polyethylene, polypropylene, polystyrene, and polyvinylchloride, along with engineering ceramics and composites. Additionally, it discusses polymerization methods, classifications of polymers, and the significance of natural and synthetic polymers in various applications.UNIT-1-VEHICLE STRUCTURE AND ENGINES.ppt

UNIT-1-VEHICLE STRUCTURE AND ENGINES.pptShanmathyAR2

╠²

The document provides an overview of automobile engineering focusing on vehicle structure, types, and the various classification of automobiles based on purpose, weight, fuel type, and capacity. It details the construction and components of vehicles, particularly the chassis and engine parts, highlighting their functions and materials used. Additionally, it explains the concepts of aerodynamics, resistance to motion, and variable valve timing in engines.UNIT-III-TRANSMISSION SYSTEMS.pptx

UNIT-III-TRANSMISSION SYSTEMS.pptxShanmathyAR2

╠²

The document details the components and functions of automobile transmission systems, including clutches and gearboxes, which facilitate smooth power transmission between the engine and wheels. It explains various types of clutches (single-plate, multi-plate, cone, centrifugal) and their characteristics, as well as different gearbox types (manual, epicyclic, automatic) and their purposes. Additionally, the document describes the role of the transfer box in four-wheel-drive systems and the advantages and disadvantages of fluid flywheels.UNIT-V-ELECTRIC AND HYBRID VEHICLES.pptx

UNIT-V-ELECTRIC AND HYBRID VEHICLES.pptxShanmathyAR2

╠²

The document discusses electric and hybrid vehicles, highlighting the advantages of electric vehicles such as zero emissions and lower operating costs, while also noting limitations like higher costs and battery recharge issues. It details various battery types used in electric vehicles, including lead-acid, nickel-cadmium, nickel-metal hydride, lithium-ion, and lithium polymer, each with specific advantages and challenges. It also explains the workings of hybrid vehicles, their configurations, and the benefits and drawbacks compared to standard vehicles.UNIT-II-ENGINE AUXILIARY SYSTEMS.pptx

UNIT-II-ENGINE AUXILIARY SYSTEMS.pptxShanmathyAR2

╠²

The document provides an in-depth overview of carburetors and fuel injection systems in internal combustion engines, detailing their functions, components, and operational mechanisms. It compares conventional carburetors with fuel injection methods, highlighting advantages such as improved power and efficiency with fuel injection systems. Various types of fuel injection systems for both gasoline and diesel engines are discussed, along with ignition systems and their respective technologies.I unit -_introduction_to_unconventional_machining_processes

I unit -_introduction_to_unconventional_machining_processesShanmathyAR2

╠²

The document outlines the history and evolution of unconventional machining processes, which emerged as a solution to the limitations of traditional methods. It highlights the need for such processes in machining advanced materials and complex shapes, including the advantages and classifications of various techniques like electrical, mechanical, and thermal processes. Despite higher costs and lower material removal rates, unconventional machining offers improved accuracy and surface finish, making it essential in industries such as aerospace and automotive.Unit 5 -RECENT TRENDS IN NON-TRADITIONAL MACHINING PROCESSES

Unit 5 -RECENT TRENDS IN NON-TRADITIONAL MACHINING PROCESSESShanmathyAR2

╠²

The document discusses thermal energy-based machining processes, emphasizing electron beam machining (EBM), laser beam machining (LBM), and plasma arc machining (PAM). It highlights the principles, mechanisms, process parameters, advantages, and disadvantages associated with each method, detailing their applications in metal cutting, drilling, and surface treatment. The document provides technical specifications and operational requirements, underscoring the advancements and challenges in these machining technologies.Unit 4 ADVANCED NANO FINISHING PROCESSES

Unit 4 ADVANCED NANO FINISHING PROCESSESShanmathyAR2

╠²

The document outlines various chemical and electro-chemical machining processes, including electro-chemical machining, grinding, honing, and deburring. It details the principles, advantages, disadvantages, and applications of these techniques, emphasizing their ability to produce burr-free components with precise tolerances. The document also compares electro-chemical machining to traditional methods, highlighting its efficiency in machining hard and brittle materials.UCM-Unit 3 CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESSES

UCM-Unit 3 CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESSESShanmathyAR2

╠²

The document outlines the principle and components of electrical energy-based metal removal processes, specifically through electric spark discharge between a tool (cathode) and a workpiece (anode). It details the construction, working mechanism, and types of dielectric fluids used, as well as the classifications of tool materials and the efficiency of different spark generating circuits. Additionally, it discusses the advantages and disadvantages of Electrical Discharge Machining (EDM) and Wire-Cut EDM (WEDM), emphasizing their applications in precise manufacturing.Unit 2 --- ucm

Unit 2 --- ucmShanmathyAR2

╠²

The document provides detailed information about various mechanical energy-based machining processes, including Abrasive Jet Machining (AJM), Water Jet Machining (WJM), and Ultrasonic Machining (USM). It outlines the construction details, parameters, advantages, and disadvantages of these processes, along with the types of materials used for machining and their applications. Each machining method is characterized by specific operational principles, tool materials, and performance factors that influence their efficiency and outcomes.Non traditinal --introduction

Non traditinal --introductionShanmathyAR2

╠²

Non-traditional machining processes were developed for applications where traditional machining using mechanical energy and direct tool-workpiece contact was impractical, incapable, or uneconomical. Non-traditional machining uses techniques like erosion, corrosion, lasers, and ultrasonic sound that do not require direct contact between the tool and workpiece. These processes are typically divided into mechanical, electrical, thermal, and chemical categories, with some advantages over traditional machining including higher accuracy, better surface finish, less tool wear, and longer tool life. However, non-traditional machining also has disadvantages like higher costs, more complex setups, and requiring skilled operators.Ad

Recently uploaded (20)

Rapid Prototyping for XR: Lecture 5 - Cross Platform Development

Rapid Prototyping for XR: Lecture 5 - Cross Platform DevelopmentMark Billinghurst

╠²

This is lecture 5 in the course about Rapid Prototyping for XR, taught by Mark Billinghurst. This lecture is about Cross Platform Development.Rapid Prototyping for XR: Lecture 6 - AI for Prototyping and Research Directi...

Rapid Prototyping for XR: Lecture 6 - AI for Prototyping and Research Directi...Mark Billinghurst

╠²

This is lecture 6 in the course on Rapid Prototyping for XR, taught on June 13th, 2025 by Mark Billinghurst. This lecture was about using AI for Prototyping and Research Directions. Modern multi-proposer consensus implementations

Modern multi-proposer consensus implementationsFran├¦ois Garillot

╠²

Multi-proposer consensus protocols let multiple validators propose blocks in parallel, breaking the single-leader throughput bottleneck of classic designs. Yet the modern multi-proposer consensus implementation has grown a lot since HotStuff. THisworkshop will explore the implementation details of recent advances ŌĆō DAG-based approaches like Narwhal and SuiŌĆÖs Mysticeti ŌĆō and reveal how implementation details translate to real-world performance gains. We focus on the nitty-gritty: how network communication patterns and data handling affect throughput and latency. New techniques such as Turbine-like block propagation (inspired by SolanaŌĆÖs erasure-coded broadcast) and lazy push gossip broadcasting dramatically cut communication overhead. These optimizations arenŌĆÖt just theoretical ŌĆō they enable modern blockchains to process over 100,000 transactions per second with finality in mere millisecondsŌĆŗ redefining what is possible in decentralized systems.

(Continuous Integration and Continuous Deployment/Delivery) is a fundamental ...

(Continuous Integration and Continuous Deployment/Delivery) is a fundamental ...ketan09101

╠²

(Continuous Integration and Continuous Deployment/Delivery) is a fundamental practice in DevOps that streamlines software development and deployment.Tesla-Stock-Analysis-and-Forecast.pptx (1).pptx

Tesla-Stock-Analysis-and-Forecast.pptx (1).pptxmoonsony54

╠²

this is data science ppt for tesla stock (linear regression)May 2025: Top 10 Read Articles in Data Mining & Knowledge Management Process

May 2025: Top 10 Read Articles in Data Mining & Knowledge Management ProcessIJDKP

╠²

Data mining and knowledge discovery in databases have been attracting a significant amount of research, industry, and media attention of late. There is an urgent need for a new generation of computational theories and tools to assist researchers in extracting useful information from the rapidly growing volumes of digital data.

This Journal provides a forum for researchers who address this issue and to present their work in a peer-reviewed open access forum. Authors are solicited to contribute to the Journal by submitting articles that illustrate research results, projects, surveying works and industrial experiences that describe significant advances in the following areas, but are not limited to these topics only.Tally.ERP 9 at a Glance.book - Tally Solutions .pdf

Tally.ERP 9 at a Glance.book - Tally Solutions .pdfShabista Imam

╠²

Tally.ERP 9 at a Glance.book, a fully completed guidance to learn tally erp 9.0Proposal for folders structure division in projects.pdf

Proposal for folders structure division in projects.pdfMohamed Ahmed

╠²

Proposal for folders structure division in projectsLearning ŌĆō Types of Machine Learning ŌĆō Supervised Learning ŌĆō Unsupervised UNI...

Learning ŌĆō Types of Machine Learning ŌĆō Supervised Learning ŌĆō Unsupervised UNI...23Q95A6706

╠²

Learning ŌĆō Types of Machine Learning ŌĆō Supervised Learning ŌĆō Unsupervised Learning- semi supervised learning - The Brain and the Neuron ŌĆō Design a Learning System ŌĆō Perspectives and Issues in Machine Learning ŌĆō Concept Learning Task ŌĆō Concept Learning as Search ŌĆō Finding a Maximally Specific Hypothesis ŌĆō Version Spaces and the Candidate Elimination Algorithm

Stay Safe Women Security Android App Project Report.pdf

Stay Safe Women Security Android App Project Report.pdfKamal Acharya

╠²

WomenŌĆÖs security is a critical issue in todayŌĆÖs world and itŌĆÖs very much needed for every individual

to be acting over such an issue. This document describes a GPS based ŌĆ£Women Security System''

that provides the combination of GPS devices as well as provide alerts and messages with an

emergency button trigger whenever somebody is in trouble They might not have so much time, all

that they have to do is generate a distress emergency signal by shaking up their phone. Our system

provides a realizable, cost effective solution to problem detection. Nowdays due to recently

happened cases such as rape by drivers or colleagues, burglary etc., women security, especially

women security has become the foremost priority of the world. System uses the Global Positioning

System (GPS) technology to find out the location of women. The information of women's position

provided by the device can be viewed on Google maps using Internet or specialized software. The

companies are looking for-ward to the security problem and require a system that will efficiently

evaluate the problem of women security working in night shifts, traveling alone. We focus on the

proposed model that can be used to deal with the security issue of women using GPS based tracking

systems.Deep Learning for Image Processing on 16 June 2025 MITS.pptx

Deep Learning for Image Processing on 16 June 2025 MITS.pptxresming1

╠²

This covers how image processing or the field of computer vision has advanced with the advent of neural network architectures ranging from LeNet to Vision transformers. It covers how deep neural network architectures have developed step-by-step from the popular CNNs to ViTs. CNNs and its variants along with their features are described. Vision transformers are introduced and compared with CNNs. It also shows how an image is processed to be given as input to the vision transformer. It give the applications of computer vision.Ad

UNIT- IV --HEAT TREATMENT.pptx

- 2. UNIT IV HEAT TREATMENT Definition ŌĆō Full annealing, glass annealing, stress relief, recrystallization and spheroidizing ŌĆō normalising, quenching, hardening and tempering of steel. Isothermal transformation diagrams ŌĆō cooling curves superimposed on Time Temperature Transformation (TTT) diagram, Critical Cooling Rate (CCR) ŌĆō Hardenability, Jominy end quench test ŌĆō austempering, martempering ŌĆō case hardening, carburizing, nitriding, cyaniding, carbonitriding ŌĆō flame and induction hardening. SYLLABUS

- 3. HEAT TREATMENT PROCESS Its a operation or combination of operations involving heating and cooling of metal / alloy in solid steels to obtain desired conditions ( Relieve stress ) and properties (like Machinability, ductility etc. ).

- 4. Heat Treatment Processes Softening Processes - Annealing Normalizing Hardening Processes - Hardening Tempering Surface Hardening Process -

- 5. HEAT TREATMENT OF STEEL The object of heat treatment is to make the steel suitable for some specific application. The shape of the grains can be altered by heating the steel to a temperature above that of recrystallization and the duration of heating and the rate of cooling. Heat treatment process classified into following: 1. Treatment that produces equilibrium condition 2. Treatment that produces non equilibrium condition

- 6. Treatments that Produce Equilibrium Condition ŌĆó The mechanical properties of steel depend upon the carbon content, the heat treatment temperature, the holding time and the cooling rate. ŌĆó Steel is heated to a temperature up to 500┬░C, small residual stresses will be relieved to a small extent to cause only a slight reduction in hardness and strength.

- 7. ANNEALING

- 8. TYPES OF ANNEALING PROCESS ŌĆó Full Annealing ŌĆó Glass Annealing ŌĆó Stress Relief Annealing ŌĆó Process Annealing ŌĆó Spherodising Annealing ŌĆó Isothermal Annealing

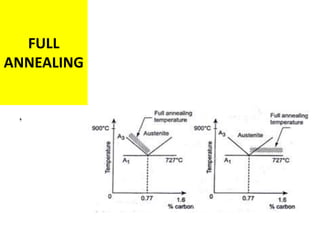

- 9. FULL ANNEALING ŌĆó Heating the steel to a temperature at or near the critical point, holding there for a time period and then allowing it to cool slowly in the furnace itself.

- 10. FULL ANNEALING ,

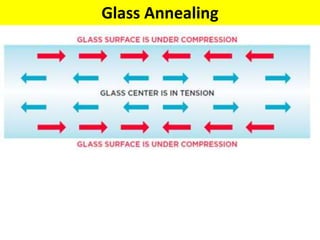

- 11. Glass Annealing Here the external surface of the glass is rapidly cooled. Because the inner material cools at a slower rate compared to the outer material, the thermal differential creates compressive stress on the glass surface and tensile stress at the inner layer of the glass.

- 12. Glass Annealing

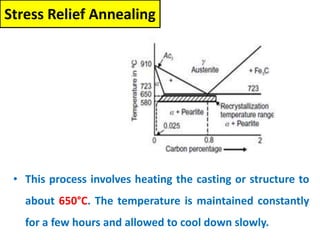

- 13. Stress Relief Annealing ŌĆó This process involves heating the casting or structure to about 650┬░C. The temperature is maintained constantly for a few hours and allowed to cool down slowly.

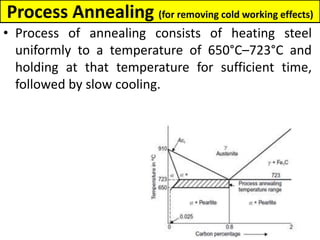

- 14. Process Annealing (for removing cold working effects) ŌĆó Process of annealing consists of heating steel uniformly to a temperature of 650┬░CŌĆō723┬░C and holding at that temperature for sufficient time, followed by slow cooling.

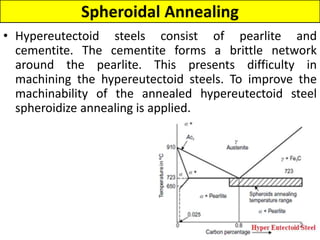

- 15. Spheroidal Annealing ŌĆó Hypereutectoid steels consist of pearlite and cementite. The cementite forms a brittle network around the pearlite. This presents difficulty in machining the hypereutectoid steels. To improve the machinability of the annealed hypereutectoid steel spheroidize annealing is applied.

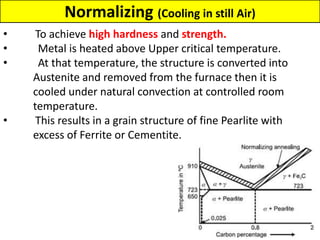

- 16. Normalizing (Cooling in still Air) ŌĆó To achieve high hardness and strength. ŌĆó Metal is heated above Upper critical temperature. ŌĆó At that temperature, the structure is converted into Austenite and removed from the furnace then it is cooled under natural convection at controlled room temperature. ŌĆó This results in a grain structure of fine Pearlite with excess of Ferrite or Cementite.

- 17. Hardening of Steels ŌĆó Its a process of heating the steel above or below the critical temperature for a particular period and then allow to cool by oil or water rapidly

- 18. TEMPERING ŌĆó For minimizing the harness and removing the internal stresses we heat the metal near to upper critical temp once again and let it for some time then cool by air

- 19. WHY ŌĆō TTT & CCT DIAGRAMS ? ŌĆó The phases martensite and bainite are non-equilibrium phase that do not appear in fe-fe3 c (iron-iron carbon) phase diagram ŌĆó also strengthening treatment like hardening and tempering are non-equilibrium process. ŌĆó in order to show the influence of varying cooling rates, that is time, on the transformation of austenite other types of diagrams are necessary. ŌĆó The time temperature transformation or TTT diagram and the continuous cooling transformation or CCT diagram are used to explain the things in the cooling operation

- 20. . ŌĆó Non-equilibrium cooling will result in different microstructures hence altered properties. ŌĆó TTT diagrams are the tools that we can use to take into account the kinetics of the transformation. ŌĆó They show the relationship between time, temperature and (percent) transformation. ŌĆó There are two types of TTT diagrams: isothermal transformation (IT) TTT diagrams continuous cooling transformation (CCT) TTT diagrams

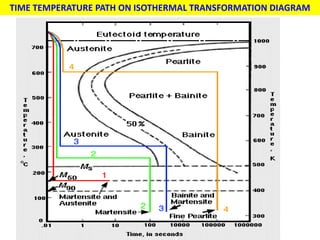

- 21. TIME TEMPERATURE PATH ON ISOTHERMAL TRANSFORMATION DIAGRAM

- 22. EFFECT OF COOLING RATE ON TTT DIAGRAM Austenite transforming into pearlite, bainite and martensite with different cooling rates is an example of this.