CNC Diversified MV-65 PM

- 1. Informationlocatedin MV-65 maintenance manual, section C. MV-65 MAINTENANCE MANUAL: CNC Diversified

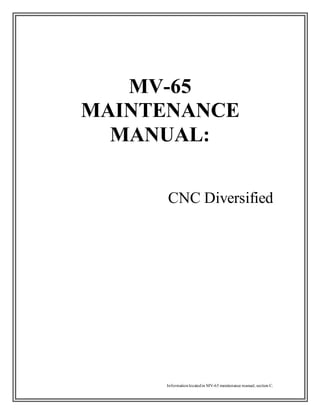

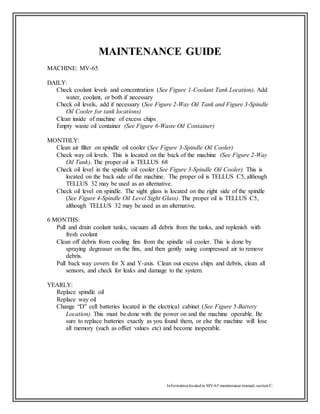

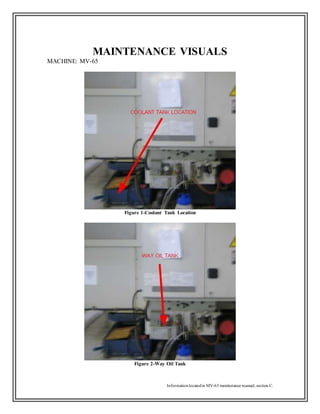

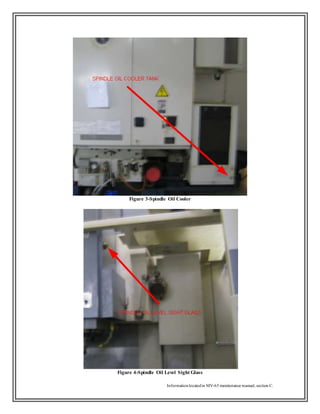

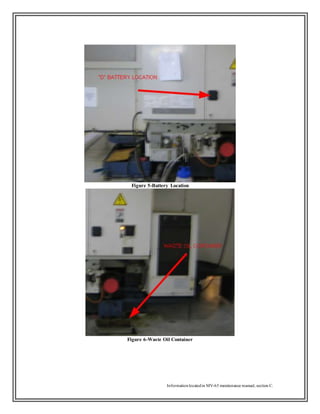

- 2. Informationlocatedin MV-65 maintenance manual, section C. MAINTENANCE GUIDE MACHINE: MV-65 DAILY: Check coolant levels and concentration (See Figure 1-Coolant Tank Location). Add water, coolant, or both if necessary Check oil levels, add if necessary (See Figure 2-Way Oil Tank and Figure 3-Spindle Oil Cooler for tank locations) Clean inside of machine of excess chips Empty waste oil container (See Figure 6-Waste Oil Container) MONTHLY: Clean air filter on spindle oil cooler (See Figure 3-Spindle Oil Cooler) Check way oil levels. This is located on the back of the machine (See Figure 2-Way Oil Tank). The proper oil is TELLUS 68 Check oil level in the spindle oil cooler (See Figure 3-Spindle Oil Cooler). This is located on the back side of the machine. The proper oil is TELLUS C5, although TELLUS 32 may be used as an alternative. Check oil level on spindle. The sight glass is located on the right side of the spindle (See Figure 4-Spindle Oil Level Sight Glass). The proper oil is TELLUS C5, although TELLUS 32 may be used as an alternative. 6 MONTHS: Pull and drain coolant tanks, vacuum all debris from the tanks, and replenish with fresh coolant Clean off debris from cooling fins from the spindle oil cooler. This is done by spraying degreaser on the fins, and then gently using compressed air to remove debris. Pull back way covers for X and Y-axis. Clean out excess chips and debris, clean all sensors, and check for leaks and damage to the system. YEARLY: Replace spindle oil Replace way oil Change âDâ cell batteries located in the electrical cabinet (See Figure 5-Battery Location). This must be done with the power on and the machine operable. Be sure to replace batteries exactly as you found them, or else the machine will lose all memory (such as offset values etc) and become inoperable.

- 3. Informationlocatedin MV-65 maintenance manual, section C. MAINTENANCE VISUALS MACHINE: MV-65 Figure 1-Coolant Tank Location Figure 2-Way Oil Tank

- 4. Informationlocatedin MV-65 maintenance manual, section C. Figure 3-Spindle Oil Cooler Figure 4-Spindle Oil Level Sight Glass

- 5. Informationlocatedin MV-65 maintenance manual, section C. Figure 5-Battery Location Figure 6-Waste Oil Container