Aboveground Fuel Storage Tanks

Download as DOCX, PDF1 like820 views

This document is a term project report on aboveground fuel storage tanks prepared by Subkhiddin MUKHIDINOV for Prof. Ĺžafak YILMAZ at Istanbul Technical University. It discusses the introduction, description, usage, design, materials, and manufacturing of fuel storage tanks. Fuel tanks are designed to safely store flammable liquids and allow for filling, gauging fuel levels, venting vapors, and feeding the engine. Design considerations include placement, shape, and calculating required volume, while common materials are aluminum, steel, and stainless steel. Manufacturing involves creating a mockup, adding openings, and leak testing after joining pieces through methods like riveting, brazing, soldering

1 of 7

Download to read offline

Recommended

Storage tanks basic training (rev 2)

Storage tanks basic training (rev 2)ledzung

Ěý

The document provides an overview of petroleum storage tank training, covering topics such as:

- Tank design types including fixed roof, internal floating roof, and floating roof tanks

- Selection of tank type based on product properties and volatility

- Tank structure including bottom/floor design, bottom and shell plates, and foundation types

- Stability calculations and anchor requirements for withstanding wind loads

- Tank inspection and safety procedures

The training aims to identify tank components, understand tank limitations, perform calculations, and operate tanks safely.Pipe system

Pipe systemFilip Gerasimov

Ěý

This document discusses various pipe systems used on ships. It describes the arrangement and components of seawater cooling systems, freshwater cooling systems, fuel oil systems, compressed air systems, lubrication oil systems, steam systems, bilge systems, firefighting systems and ballast systems. Key points covered include the layout and operation of sea chests, filters, pumps and valves for cooling water intake and distribution. It also outlines the storage, transfer and treatment of fuel oil including purifiers, settling tanks and service tanks.Training Presentation on Diesel Engine

Training Presentation on Diesel EngineAbhishek Jakhar

Ěý

This document presents information about diesel engines from an engineering workshop. It discusses the basic working principles of diesel engines, including compression ignition and the diesel cycle. It also covers key engine components like the engine block, crankshaft, pistons, connecting rods, cylinder head, camshaft, and turbocharger. The document categorizes engines based on criteria like number of strokes, ignition type, cylinder arrangement, and speed. It defines important engine terminology and identifies components on diagrams of engine sections and systems.Lpg lng cargo_handling Merchant Shipping

Lpg lng cargo_handling Merchant Shippingydmisra

Ěý

The document discusses procedures for handling LPG and LNG cargo on ships. It describes key steps including inerting cargo tanks, gassing up tanks, cooling down tanks, loading cargo, refrigerating cargo during transport, discharging cargo, and aerating tanks after discharge. Processes like inerting, gassing up, and cooling down prepare cargo tanks for loading or prevent over-pressurization. Refrigeration maintains cargo temperature during transport. Discharge methods depend on ship and terminal storage types. Special procedures are required when changing between cargoes like ammonia and LPG.Storage tanks _emissions_and_emission_reductions_201312

Storage tanks _emissions_and_emission_reductions_201312salah jallali

Ěý

This document discusses emissions from atmospheric storage tanks and methods to reduce them. It provides details on:

- Types of storage tank designs and their relative emissions levels. Fixed roof tanks without internal floating roofs have the highest emissions while internal floating roof tanks have the lowest.

- Methods to reduce tank emissions including installing internal or external floating roofs, vapor recovery systems, tank color and configuration options.

- Case studies on retrofitting existing external floating roof tanks with internal floating roofs to significantly reduce emissions by 99%.

- Options for measuring and quantifying tank emissions ranging from lower cost infrared cameras to higher cost DIAL and SOF measurement methods.Various Mechanical Units Involved in The Bottling Of LPG cylinders

Various Mechanical Units Involved in The Bottling Of LPG cylindersMohit Dhull

Ěý

LPG BOTTLING PLANTS

MECHANICAL UNITS INVOLVED IN THE PROCESS OF FILLING OF LPG CYLINDERS

REFERENCES USED

LPG DETAILS ,RECOVERY,PRODUCTION

FIRE SAFETY SYSTEMSPpt

PptMarsxo Sxiietiiee

Ěý

This document provides an overview and summary of a basic training course on petroleum storage tanks. It discusses various tank types including fixed roof tanks, internal floating roof tanks, and floating roof tanks. It covers tank design elements like the structure of the tank bottom and floor, thickness of bottom plates, and attachment of the bottom to the shell. It also addresses tank foundations, including the need for foundations to allow for leak detection. The goals of the training are identified as learning to identify tank types and equipment, understand tank limitations, perform volume calculations, and operate tanks safely.MULTI-POINT FUEL INJECTION SYSTEM

MULTI-POINT FUEL INJECTION SYSTEMMihir Patel

Ěý

Multipoint fuel injection (MPFI) systems provide better control of the air-fuel ratio compared to carburetors. MPFI systems use multiple fuel injectors, with one injector per cylinder, to inject fuel into the engine's intake ports or manifold. This allows supplying the optimum air-fuel ratio to each cylinder for all operating conditions. MPFI systems are electronically controlled using sensors to monitor various engine parameters and optimize fuel delivery and emissions performance. While more complex than carburetors, MPFI systems improve fuel efficiency, power, and reduce emissions.Introduction to Storage Tanks

Introduction to Storage TanksAnkur Sharma

Ěý

This document provides an introduction and overview of different types of storage tanks. It discusses 8 main types of storage tanks: fixed-roof tanks, external floating roof tanks, internal floating roof tanks, domed external floating roof tanks, horizontal tanks, pressure tanks, variable vapor space tanks, and LNG storage tanks. Each tank type is designed for storing different types of liquids and gases and has distinct features such as floating roofs, fixed roofs, insulation, and sizes that can range from meters to over 100 meters in diameter. The document also discusses containment basins, which storage tanks are often placed inside of to contain spills.Cng ppt

Cng pptShubhangam Mayank

Ěý

This document provides information about compressed natural gas (CNG) vehicles. It discusses the benefits of CNG which include lower costs, better engine life, and reduced emissions compared to gasoline. Proper training is required for maintenance on CNG vehicles since the oil does not need to be changed as frequently. The top countries using CNG vehicles are Iran, Pakistan, and Argentina. In conclusion, while CNG vehicles have advantages, their tanks require more storage space and initial costs are higher than gasoline vehicles.NATURAL GAS DEHYDRATION

NATURAL GAS DEHYDRATION Ahmed Shoman

Ěý

ALL ABOUT NATURAL GAS : DEFINITION,FORMATION,PROPERTIES,COMPOSITION,PHASE BEHAVIOR ,CONDITIONING"DEHYDRATION ,SWETENING" AND FINAL PROCESSING TO END USER PRODUCTS Storage Tank Safety

Storage Tank SafetyBipin ShyamSundar Tiwari

Ěý

Atmospheric Storage Tank Safety is dependent on various factors. To name a few:

1. Liquid movement in and out of the tank

2. Weather condition changes

3. Fire exposure

The presentation shows a basic overview of how we can create safe environment for storage and transportation of fluids. Automotive System

Automotive System S. Sathishkumar

Ěý

This document provides an overview of internal combustion engines. It begins with an introduction that defines internal combustion engines as heat engines that convert the chemical energy in fuel into mechanical energy. It then covers classifications of engines including by ignition type (spark ignition or compression ignition), engine cycle (four-stroke or two-stroke), valve location, design, cylinder positioning and number, air intake process, fuel input, fuel used, application, and cooling type. The document also discusses important engine components like the cylinder block, cylinders, cylinder head, valve train, pistons, connecting rod, and crankshaft. It concludes with sections on engine cycles, thermochemistry and fuels, emissions and air pollution.Fire Pump Presentation.pptx

Fire Pump Presentation.pptxThushan9

Ěý

This presentation discusses NFPA 20 standards for fire pump sets. It provides background on NFPA and describes how NFPA sets standards for fire safety issues. NFPA 20 contains requirements for fire pumps, including that they must operate at 150% rated capacity at 65% total rated head. The presentation reviews pump types, motor and diesel engine selection requirements, control panels, accessories, and examples of electric and diesel pump sets. evaporative emission control system

evaporative emission control systemitaeyen

Ěý

The evaporative emission control system prevents fuel vapors from escaping into the atmosphere. It includes a canister that absorbs fuel vapors from the fuel tank, and solenoid valves including the purge control solenoid valve and pressure control solenoid valve that are controlled by the ECM. The system also has a fuel cut valve in the fuel tank and a fuel tank pressure sensor that is used to diagnose the system and check for leaks by varying the fuel tank pressure and measuring it.Crdi ppt

Crdi pptPoornima Group of Institutions, Jaipur

Ěý

Crdi technology is more efficient and advance technology in the field of automobile engineering. This technology is using at a large scale by a number of car companies. In this presentation you will find the basic principle, working, and component description of crdi technology.Introduction of Boiler

Introduction of BoilerMarine Study

Ěý

A boiler is a closed vessel that heats water or another fluid. Boilers are constructed from low-carbon steel and have corrugated furnaces for strength. On ships, steam is used for heating, powering turbines, pumps, and other machinery. There are different types of boilers classified by their orientation, circulation method, pressure rating, and whether water or hot gases pass through tubes. Fire tube boilers have hot gases passing through tubes surrounded by water while water tube boilers have water passing through tubes surrounded by hot gases. Packaged boilers are self-contained and efficient units that produce steam quickly.Engine components and operation

Engine components and operationpratik darji

Ěý

concept of this ppt is ENGINE COMPONENTS AND OPERATION in ic engine...this have brief concept of ic engine component and operation....

ppt made by PRATIK DARJI..Air Intake & Exhaust System of Automobiles and its Recent Developments

Air Intake & Exhaust System of Automobiles and its Recent DevelopmentsMd. Muntasir R- Rafi

Ěý

A presentation on operation procedure of air intake & exhaust system of automobiles & its recent developments in brief.Transmission system

Transmission systemRatnadeepsinh Jadeja

Ěý

Introduction to the Transmission system, Requirements of the transmission system, main units of the transmission system, types of the transmission system, clutch, functions of a clutch, requirements of a clutch, principle of operation of a clutch, friction materials, classification of a clutch, cone clutch, single-plate clutch, multi-plate clutch

centrifugal clutch, hydraulic coupling, hydraulic torque converter.Fuel system fundamentals

Fuel system fundamentalsamged radhi

Ěý

This document provides an overview of fuel systems, including the main components and how they work. It compares carbureted and fuel injected systems, describing the different types of fuel injection. Electronic fuel injection uses sensors, actuators, and a computer to precisely meter fuel delivery. The computer receives feedback from oxygen sensors to continuously adjust the air-fuel ratio for optimal performance and emissions.Piping system

Piping systemRajneesh20042010

Ěý

The document describes the piping systems on a ship. It discusses the importance of an efficient piping system and provides examples of common piping systems like bilge, ballast, fuel, cooling water, lubrication oil, compressed air, steam, and cargo tank systems. It emphasizes preparing accurate piping plans and diagrams using standardized symbols and labeling key details like pipe sizes, flow directions, and component capacities. Common arrangements for pumping, drainage, overflows, and other aspects of key systems are illustrated with diagrams.Storage Tank.pdf

Storage Tank.pdfUniversity of Sarajevo, Manufacturing Technology:

Ěý

This document provides an overview and training on petroleum storage tanks. It discusses tank design types including fixed roof, floating roof, and pressurized storage tanks. It covers tank structure, fittings, inspection, measurement, and safety. The training outlines the goals of identifying tank types and equipment, understanding limitations, calculating volumes, and safe operation. Tank design considerations include product properties, stability calculations, and foundation types.A SIMPLE OR ELEMENTRARY CARBURETOR / EFI SYSTEM

A SIMPLE OR ELEMENTRARY CARBURETOR / EFI SYSTEMUniversity of ruhuna Srilanka

Ěý

A carburetor performs this function mechanically; relying on differences in air pressure inside the carburetor to regulate fuel flow. EFI (Electronic Fuel Injection) performs this function electronically using computer-controlled fuel injectors to admit pressurized fuel as required by throttle position.67984329 stratified-charged-engine-ppt

67984329 stratified-charged-engine-pptUsha Kumar

Ěý

The stratified charge engine provides a rich air-fuel mixture near the spark plug for easy ignition using a separate inlet valve. The remainder of the cylinder contains a lean mixture that is ignited by the burning of the rich mixture. This allows the engine to operate with higher compression ratios and leaner mixtures than conventional engines, improving fuel efficiency. Honda introduced the first production stratified charge engine, the CVCC, in 1976, and it used 15-20% less fuel than non-stratified engines of the time.Engine Presentation

Engine PresentationZeenoside

Ěý

The document provides an overview of the basic components and functions of internal combustion engines. It discusses the different types of engines including 4-stroke, V8, and 2-stroke engines. It also describes the key components that an engine needs to operate such as fuel, air, spark, and compression. Pistons, crankshafts, camshafts, valves and their functions are explained. The 4-stroke combustion cycle and engine timing are also summarized.CRDI ENGINE

CRDI ENGINE HOME

Ěý

CRDI stands for common rail direct injection and directly injects fuel into engine cylinders via a single common rail connected to all fuel injectors. It was introduced to remove drawbacks of earlier fuel systems and allows even petrol engines to run with very lean fuel mixtures. The key components are a high pressure fuel pump, common rail, injectors, and engine control unit. CRDI provides benefits like 25% more power and torque, superior pickup, reduced noise and vibrations, and lower fuel consumption. While it has higher initial costs and maintenance than older systems, CRDI lowers emissions and improves engine performance.octane and cetane numbers

octane and cetane numbersajitthorat

Ěý

Octane and cetane numbers measure a fuel's resistance to self-ignition or knocking. Octane numbers refer to gasoline's resistance to knocking, measured using two tests - the Research Octane Number (RON) and Motor Octane Number (MON). Cetane numbers refer to diesel fuel's ease of ignition, with higher numbers indicating easier ignition. Fuels like gasoline and diesel have different typical octane/cetane numbers and properties that affect their use in engines.Stress analysis of storage tank piping - Jeba Anand

Stress analysis of storage tank piping - Jeba AnandJeba Anand Nadar

Ěý

1. The document discusses stress analysis of storage tank piping. It covers classification of tanks based on fluid type and construction, modeling of tanks in Caesar software, API 650 calculations, and nozzle checks as per API 650 standards.

2. Key points include classification of tanks as fixed roof, floating roof, horizontal pressure, and Horton sphere types. Modeling of tanks in Caesar involves defining displacements for tank settlement and bulging. Nozzle checks involve verifying loads do not exceed allowable limits given tank dimensions and properties.

3. Piping connected to tanks must be properly routed and supported, accounting for tank behavior due to settlement, thermal growth, and bulging under liquid head pressure. Spring supports mayTank design - word

Tank design - wordmoamen mohamed

Ěý

This document discusses different types of storage tanks used in refineries and chemical plants. It describes atmospheric storage tanks, which operate at approximately atmospheric pressure, including fixed-roof tanks, floating-roof tanks, and fixed-roof tanks with an internal floating roof. Low-temperature and low-pressure storage tanks are also discussed. Standards for storage tank design include API-650 for atmospheric tanks and API-620 for low-pressure tanks. Floating roof tanks are described as minimizing vapor losses by maintaining a small vapor space or eliminating it completely.More Related Content

What's hot (20)

Introduction to Storage Tanks

Introduction to Storage TanksAnkur Sharma

Ěý

This document provides an introduction and overview of different types of storage tanks. It discusses 8 main types of storage tanks: fixed-roof tanks, external floating roof tanks, internal floating roof tanks, domed external floating roof tanks, horizontal tanks, pressure tanks, variable vapor space tanks, and LNG storage tanks. Each tank type is designed for storing different types of liquids and gases and has distinct features such as floating roofs, fixed roofs, insulation, and sizes that can range from meters to over 100 meters in diameter. The document also discusses containment basins, which storage tanks are often placed inside of to contain spills.Cng ppt

Cng pptShubhangam Mayank

Ěý

This document provides information about compressed natural gas (CNG) vehicles. It discusses the benefits of CNG which include lower costs, better engine life, and reduced emissions compared to gasoline. Proper training is required for maintenance on CNG vehicles since the oil does not need to be changed as frequently. The top countries using CNG vehicles are Iran, Pakistan, and Argentina. In conclusion, while CNG vehicles have advantages, their tanks require more storage space and initial costs are higher than gasoline vehicles.NATURAL GAS DEHYDRATION

NATURAL GAS DEHYDRATION Ahmed Shoman

Ěý

ALL ABOUT NATURAL GAS : DEFINITION,FORMATION,PROPERTIES,COMPOSITION,PHASE BEHAVIOR ,CONDITIONING"DEHYDRATION ,SWETENING" AND FINAL PROCESSING TO END USER PRODUCTS Storage Tank Safety

Storage Tank SafetyBipin ShyamSundar Tiwari

Ěý

Atmospheric Storage Tank Safety is dependent on various factors. To name a few:

1. Liquid movement in and out of the tank

2. Weather condition changes

3. Fire exposure

The presentation shows a basic overview of how we can create safe environment for storage and transportation of fluids. Automotive System

Automotive System S. Sathishkumar

Ěý

This document provides an overview of internal combustion engines. It begins with an introduction that defines internal combustion engines as heat engines that convert the chemical energy in fuel into mechanical energy. It then covers classifications of engines including by ignition type (spark ignition or compression ignition), engine cycle (four-stroke or two-stroke), valve location, design, cylinder positioning and number, air intake process, fuel input, fuel used, application, and cooling type. The document also discusses important engine components like the cylinder block, cylinders, cylinder head, valve train, pistons, connecting rod, and crankshaft. It concludes with sections on engine cycles, thermochemistry and fuels, emissions and air pollution.Fire Pump Presentation.pptx

Fire Pump Presentation.pptxThushan9

Ěý

This presentation discusses NFPA 20 standards for fire pump sets. It provides background on NFPA and describes how NFPA sets standards for fire safety issues. NFPA 20 contains requirements for fire pumps, including that they must operate at 150% rated capacity at 65% total rated head. The presentation reviews pump types, motor and diesel engine selection requirements, control panels, accessories, and examples of electric and diesel pump sets. evaporative emission control system

evaporative emission control systemitaeyen

Ěý

The evaporative emission control system prevents fuel vapors from escaping into the atmosphere. It includes a canister that absorbs fuel vapors from the fuel tank, and solenoid valves including the purge control solenoid valve and pressure control solenoid valve that are controlled by the ECM. The system also has a fuel cut valve in the fuel tank and a fuel tank pressure sensor that is used to diagnose the system and check for leaks by varying the fuel tank pressure and measuring it.Crdi ppt

Crdi pptPoornima Group of Institutions, Jaipur

Ěý

Crdi technology is more efficient and advance technology in the field of automobile engineering. This technology is using at a large scale by a number of car companies. In this presentation you will find the basic principle, working, and component description of crdi technology.Introduction of Boiler

Introduction of BoilerMarine Study

Ěý

A boiler is a closed vessel that heats water or another fluid. Boilers are constructed from low-carbon steel and have corrugated furnaces for strength. On ships, steam is used for heating, powering turbines, pumps, and other machinery. There are different types of boilers classified by their orientation, circulation method, pressure rating, and whether water or hot gases pass through tubes. Fire tube boilers have hot gases passing through tubes surrounded by water while water tube boilers have water passing through tubes surrounded by hot gases. Packaged boilers are self-contained and efficient units that produce steam quickly.Engine components and operation

Engine components and operationpratik darji

Ěý

concept of this ppt is ENGINE COMPONENTS AND OPERATION in ic engine...this have brief concept of ic engine component and operation....

ppt made by PRATIK DARJI..Air Intake & Exhaust System of Automobiles and its Recent Developments

Air Intake & Exhaust System of Automobiles and its Recent DevelopmentsMd. Muntasir R- Rafi

Ěý

A presentation on operation procedure of air intake & exhaust system of automobiles & its recent developments in brief.Transmission system

Transmission systemRatnadeepsinh Jadeja

Ěý

Introduction to the Transmission system, Requirements of the transmission system, main units of the transmission system, types of the transmission system, clutch, functions of a clutch, requirements of a clutch, principle of operation of a clutch, friction materials, classification of a clutch, cone clutch, single-plate clutch, multi-plate clutch

centrifugal clutch, hydraulic coupling, hydraulic torque converter.Fuel system fundamentals

Fuel system fundamentalsamged radhi

Ěý

This document provides an overview of fuel systems, including the main components and how they work. It compares carbureted and fuel injected systems, describing the different types of fuel injection. Electronic fuel injection uses sensors, actuators, and a computer to precisely meter fuel delivery. The computer receives feedback from oxygen sensors to continuously adjust the air-fuel ratio for optimal performance and emissions.Piping system

Piping systemRajneesh20042010

Ěý

The document describes the piping systems on a ship. It discusses the importance of an efficient piping system and provides examples of common piping systems like bilge, ballast, fuel, cooling water, lubrication oil, compressed air, steam, and cargo tank systems. It emphasizes preparing accurate piping plans and diagrams using standardized symbols and labeling key details like pipe sizes, flow directions, and component capacities. Common arrangements for pumping, drainage, overflows, and other aspects of key systems are illustrated with diagrams.Storage Tank.pdf

Storage Tank.pdfUniversity of Sarajevo, Manufacturing Technology:

Ěý

This document provides an overview and training on petroleum storage tanks. It discusses tank design types including fixed roof, floating roof, and pressurized storage tanks. It covers tank structure, fittings, inspection, measurement, and safety. The training outlines the goals of identifying tank types and equipment, understanding limitations, calculating volumes, and safe operation. Tank design considerations include product properties, stability calculations, and foundation types.A SIMPLE OR ELEMENTRARY CARBURETOR / EFI SYSTEM

A SIMPLE OR ELEMENTRARY CARBURETOR / EFI SYSTEMUniversity of ruhuna Srilanka

Ěý

A carburetor performs this function mechanically; relying on differences in air pressure inside the carburetor to regulate fuel flow. EFI (Electronic Fuel Injection) performs this function electronically using computer-controlled fuel injectors to admit pressurized fuel as required by throttle position.67984329 stratified-charged-engine-ppt

67984329 stratified-charged-engine-pptUsha Kumar

Ěý

The stratified charge engine provides a rich air-fuel mixture near the spark plug for easy ignition using a separate inlet valve. The remainder of the cylinder contains a lean mixture that is ignited by the burning of the rich mixture. This allows the engine to operate with higher compression ratios and leaner mixtures than conventional engines, improving fuel efficiency. Honda introduced the first production stratified charge engine, the CVCC, in 1976, and it used 15-20% less fuel than non-stratified engines of the time.Engine Presentation

Engine PresentationZeenoside

Ěý

The document provides an overview of the basic components and functions of internal combustion engines. It discusses the different types of engines including 4-stroke, V8, and 2-stroke engines. It also describes the key components that an engine needs to operate such as fuel, air, spark, and compression. Pistons, crankshafts, camshafts, valves and their functions are explained. The 4-stroke combustion cycle and engine timing are also summarized.CRDI ENGINE

CRDI ENGINE HOME

Ěý

CRDI stands for common rail direct injection and directly injects fuel into engine cylinders via a single common rail connected to all fuel injectors. It was introduced to remove drawbacks of earlier fuel systems and allows even petrol engines to run with very lean fuel mixtures. The key components are a high pressure fuel pump, common rail, injectors, and engine control unit. CRDI provides benefits like 25% more power and torque, superior pickup, reduced noise and vibrations, and lower fuel consumption. While it has higher initial costs and maintenance than older systems, CRDI lowers emissions and improves engine performance.octane and cetane numbers

octane and cetane numbersajitthorat

Ěý

Octane and cetane numbers measure a fuel's resistance to self-ignition or knocking. Octane numbers refer to gasoline's resistance to knocking, measured using two tests - the Research Octane Number (RON) and Motor Octane Number (MON). Cetane numbers refer to diesel fuel's ease of ignition, with higher numbers indicating easier ignition. Fuels like gasoline and diesel have different typical octane/cetane numbers and properties that affect their use in engines.Similar to Aboveground Fuel Storage Tanks (20)

Stress analysis of storage tank piping - Jeba Anand

Stress analysis of storage tank piping - Jeba AnandJeba Anand Nadar

Ěý

1. The document discusses stress analysis of storage tank piping. It covers classification of tanks based on fluid type and construction, modeling of tanks in Caesar software, API 650 calculations, and nozzle checks as per API 650 standards.

2. Key points include classification of tanks as fixed roof, floating roof, horizontal pressure, and Horton sphere types. Modeling of tanks in Caesar involves defining displacements for tank settlement and bulging. Nozzle checks involve verifying loads do not exceed allowable limits given tank dimensions and properties.

3. Piping connected to tanks must be properly routed and supported, accounting for tank behavior due to settlement, thermal growth, and bulging under liquid head pressure. Spring supports mayTank design - word

Tank design - wordmoamen mohamed

Ěý

This document discusses different types of storage tanks used in refineries and chemical plants. It describes atmospheric storage tanks, which operate at approximately atmospheric pressure, including fixed-roof tanks, floating-roof tanks, and fixed-roof tanks with an internal floating roof. Low-temperature and low-pressure storage tanks are also discussed. Standards for storage tank design include API-650 for atmospheric tanks and API-620 for low-pressure tanks. Floating roof tanks are described as minimizing vapor losses by maintaining a small vapor space or eliminating it completely.group 6 ppt presentation in group 6.pptx

group 6 ppt presentation in group 6.pptxyohannestube

Ěý

This document describes the design of a hydraulic floor jack. It discusses:

- The components of a typical hydraulic floor jack and how it works using Pascal's law.

- The objectives of designing an easy to use jack that can lift vehicles to 18 inches and be durable.

- Potential problems with existing jacks like difficulty of use and safety issues.

- The methodology used in the design process including analyzing current designs and testing a prototype.

- The typical materials used like steel for strength and aluminum to reduce weight.Fuel Tank Cap

Fuel Tank CapLebow-Eaton Caps & Necks (TE Connectivity)

Ěý

fuel tank cap and fuel cap area units are essential on various vehicle tanks and storage containers. different styles cool the tank to relieve pressure or vapor, while others offer an associated hermetic seal.

A fuel cap prevents the entry of foreign materials and therefore the escape of fuel from the tank.

Aboveground_storage_tank_design_and_operation.pdf

Aboveground_storage_tank_design_and_operation.pdfFerranCabre

Ěý

1) Vertical aboveground storage tanks are commonly used to store liquids and gases in processing facilities. They can have fixed roofs or floating roofs, and selection depends on factors like the stored material's true vapor pressure.

2) There are two main types of floating roof tanks: external floating roofs that float directly on the stored liquid, and internal floating roofs that float inside a fixed roof tank.

3) Proper design of storage tanks involves considerations for process parameters, mechanical design, environmental regulations, structural requirements, and other safety factors. Standards like those from API provide guidelines for design, construction, and operation.Lect.8.pptx

Lect.8.pptxTEPDesign1

Ěý

This document discusses various types of storage tanks used for liquids and gases. It describes fixed roof tanks and floating roof tanks. Fixed roof tanks are simpler and cheaper but allow vapors to escape. Floating roof tanks reduce material losses and explosion risk by trapping vapors under a floating roof. External floating roof tanks are open-top while internal floating roof tanks have a roof inside a cone roof tank. Tank design considers the stored substance's flash point and tanks must withstand hydrostatic pressure. Proper construction and maintenance are needed to prevent tank failures from corrosion, thin walls or faulty welding.Parts of a Diesel Engine

Parts of a Diesel EngineLisan Taha Açın

Ěý

This document summarizes several key stationary parts of a diesel engine:

1) The bedplate supports the weight of the engine and maintains crankshaft alignment, while allowing for flexibility.

2) The A-frame carries crosshead guides and supports the engine structure.

3) The cylinder block forms the engine's rigid structure and provides passages for coolant, oil, and crankshaft/camshaft bearings. Stern Tube and Shafting Arrangements

Stern Tube and Shafting ArrangementsMohammud Hanif Dewan M.Phil.

Ěý

The stern tube is a hollow tube running through the bottom of a ship that contains the propeller shaft. It connects the main engine to the propeller and supports the large weight of the propeller. Stern tubes are designed to keep water from leaking into the ship while allowing the propeller shaft to rotate freely. They contain bearings lubricated with oil or water to reduce friction and prevent leakage between the stern tube and propeller shaft. Modern systems aim to improve lubrication and reduce contamination of lubricants with water for more efficient propulsion.Types of storage tanks

Types of storage tanksPrajapati_15

Ěý

tanks are used in general chemical industries classified as: atmospheric storage tanks, pressure storage tanks and refrigerated storage tanksUNIT-1-VEHICLE STRUCTURE AND ENGINES.ppt

UNIT-1-VEHICLE STRUCTURE AND ENGINES.pptDineshKumar4165

Ěý

Types of automobiles, vehicle construction and different layouts, chassis, frame and body, resistances to vehicle aerodynamics (various resistances and moments involved), IC engines-components functions and materials, variable valve timing (VVT).Final Brochure Web

Final Brochure WebRavindra Vasisht

Ěý

Hers is a literature of Lincoln Composites, USA giving details of the range of type 4 composite cylinders on offerEquipment question bank

Equipment question bankBùi Quốc Dũng (Jason)

Ěý

The document provides an overview of pressure vessel design and components. It discusses key terms like pressure vessel and stresses. The main types of equipment discussed are pressure vessels, storage vessels, distillation columns, heat exchangers, and reactors. Pressure vessels are usually spherical or cylindrical and must be properly designed to avoid failure under stresses from internal pressure, external forces, corrosion and more. Design involves selecting materials and calculating thicknesses for parts like shells, heads, nozzles and supports.1.3 diesel engine stationary components

1.3 diesel engine stationary componentsengineman

Ěý

The document provides information on the key components that make up a diesel engine, including the cylinder block, cylinder liners, crankcase, sump, end plates, access covers, cylinder head, and engine mountings. It describes the purpose and location of each component as well as common material types and designs used.UNIT-1-VEHICLE STRUCTURE AND ENGINES.ppt

UNIT-1-VEHICLE STRUCTURE AND ENGINES.pptShanmathyAR2

Ěý

VEHICLE STRUCTURE AND ENGINES

Types of automobiles, vehicle construction and different layouts, chassis, frame and body, resistances to vehicle aerodynamics (various resistances and moments involved), IC engines-components functions and materials, variable valve timing (VVT).

UNIT-1-VEHICLE STRUCTURE AND ENGINES.ppt

UNIT-1-VEHICLE STRUCTURE AND ENGINES.pptprakash0712

Ěý

Types of automobiles – vehicle construction and different layouts – chassis, frame and body – resistances to vehicle aerodynamics (various resistances and moments involved) – IC engines - components, functions and materials – Variable Valve Timing (VVT).Underground Storage Tank,Underground HSD Tank,Petroleum Tank,Oil Tank,Fuel Ta...

Underground Storage Tank,Underground HSD Tank,Petroleum Tank,Oil Tank,Fuel Ta...SEO Tech Solution

Ěý

https://bit.ly/3Sdfe37

https://bit.ly/3xAl3jc

https://bit.ly/3eOobS3

https://bit.ly/3QSpuwS

https://bit.ly/3QXplYO

https://bit.ly/3dsCqMg

https://bit.ly/3dpzL5K

https://bit.ly/3RZxht0

https://bit.ly/3T3Anh5

https://bit.ly/3VnZjl2

https://bit.ly/3VnrTD5

https://bit.ly/3RVXvgg

project paper

project paperChina three gorges university

Ěý

The document describes the design of a six-cylinder internal combustion engine. It includes summaries of the design and function of key engine components like the piston, engine block, crankshaft, valves cover, rocker arm, oil pan, intake manifold, exhaust manifold, engine valves, cylinder head, camshaft, air turbo, and air filter. CAD drawings were created using Solidworks to illustrate the engine structure and connection of parts. Calculations were performed to determine appropriate materials, forces, stresses, and ensure equilibrium during operation. An animation was created to simulate the designed engine.Final Report Of KPT

Final Report Of KPTHafiz Khalil Ahmed Siddiqui

Ěý

This document provides information about the systems and components on board the bucket dredger Aftab operated by the Karachi Port Trust. It describes the main diesel engine, auxiliary engine, and harbor engine that power generators on board. It also discusses the air compressor, hydro-fore tanks, bilge ballast pump, and diesel fuel tanks. The document was submitted as part of an internship report on the bucket dredger by two mechanical engineering students.Recently uploaded (20)

Design and Analysis of Algorithms Unit 5

Design and Analysis of Algorithms Unit 5sureshkumara29

Ěý

Algorithm design techniques include:

Brute Force

Greedy Algorithms

Divide-and-Conquer

Dynamic Programming

Reduction / Transform-and-Conquer

Backtracking and Branch-and-Bound

Randomization

Approximation

Recursive Approach

What is an algorithm?

An Algorithm is a procedure to solve a particular problem in a finite number of steps for a finite-sized input.

The algorithms can be classified in various ways. They are:

Implementation Method

Design Method

Design Approaches

Other Classifications

In this article, the different algorithms in each classification method are discussed.

The classification of algorithms is important for several reasons:

Organization: Algorithms can be very complex and by classifying them, it becomes easier to organize, understand, and compare different algorithms.

Problem Solving: Different problems require different algorithms, and by having a classification, it can help identify the best algorithm for a particular problem.

Performance Comparison: By classifying algorithms, it is possible to compare their performance in terms of time and space complexity, making it easier to choose the best algorithm for a particular use case.

Reusability: By classifying algorithms, it becomes easier to re-use existing algorithms for similar problems, thereby reducing development time and improving efficiency.

Research: Classifying algorithms is essential for research and development in computer science, as it helps to identify new algorithms and improve existing ones.

Overall, the classification of algorithms plays a crucial role in computer science and helps to improve the efficiency and effectiveness of solving problems.

Classification by Implementation Method: There are primarily three main categories into which an algorithm can be named in this type of classification. They are:

Recursion or Iteration: A recursive algorithm is an algorithm which calls itself again and again until a base condition is achieved whereas iterative algorithms use loops and/or data structures like stacks, queues to solve any problem. Every recursive solution can be implemented as an iterative solution and vice versa.

Example: The Tower of Hanoi is implemented in a recursive fashion while Stock Span problem is implemented iteratively.

Exact or Approximate: Algorithms that are capable of finding an optimal solution for any problem are known as the exact algorithm. For all those problems, where it is not possible to find the most optimized solution, an approximation algorithm is used. Approximate algorithms are the type of algorithms that find the result as an average outcome of sub outcomes to a problem.

Example: For NP-Hard Problems, approximation algorithms are used. Sorting algorithms are the exact algorithms.

Serial or Parallel or Distributed Algorithms: In serial algorithms, one instruction is executed at a time while parallel algorithms are those in which we divide the problem into subproblems and execute them on different processors. Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

Ěý

Kalite Politikamız

Taykon Çelik için kalite, hayallerinizi bizlerle paylaştığınız an başlar. Proje çiziminden detayların çözümüne, detayların çözümünden üretime, üretimden montaja, montajdan teslime hayallerinizin gerçekleştiğini gördüğünüz ana kadar geçen tüm aşamaları, çalışanları, tüm teknik donanım ve çevreyi içine alır KALİTE.AI-Powered Power Converter Design Workflow.pdf

AI-Powered Power Converter Design Workflow.pdfAleksandr Terlo

Ěý

Blending human expertise with AI-driven optimization for efficient power converter design.ESIT135 Problem Solving Using Python Notes of Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-3prasadmutkule1

Ěý

ESIT135 Problem Solving Using Python Notes of Unit-3 The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ěý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

Ěý

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. Von karman Equation full derivation .pdf

Von karman Equation full derivation .pdfEr. Gurmeet Singh

Ěý

Von karman Equation full derivation

By Er. GURMEET SINGH

G.C.E.T JAMMU

Contact: gurmeet.b.tech@gmail.com

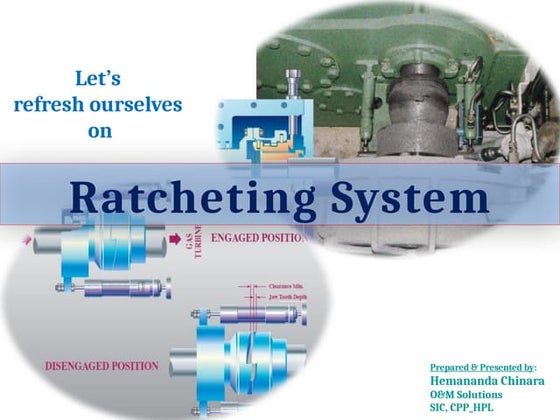

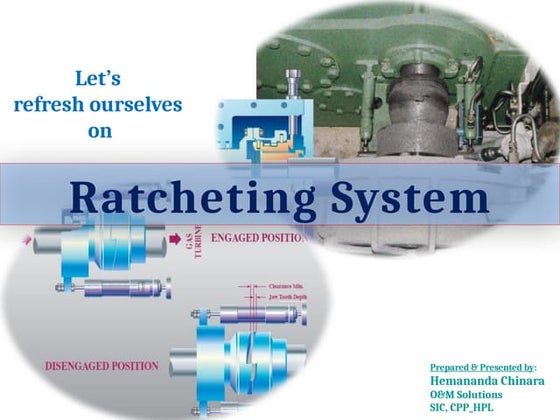

M.tech Transportation Engineering GE 6B GT Ratcheting Animation- Hemananda Chinara.ppsx

GE 6B GT Ratcheting Animation- Hemananda Chinara.ppsxHemananda Chinara

Ěý

GE 6B Gas Turbine Ratcheting Mechanism Animation made by Hemananda Chinara, SIC, CPP, HPL.Unit 1- Review of Basic Concepts-part 1.pptx

Unit 1- Review of Basic Concepts-part 1.pptxSujataSonawane11

Ěý

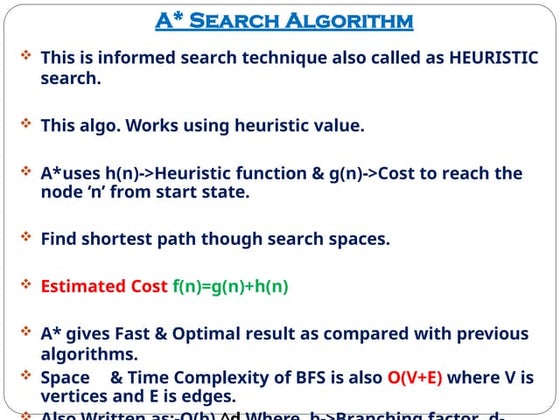

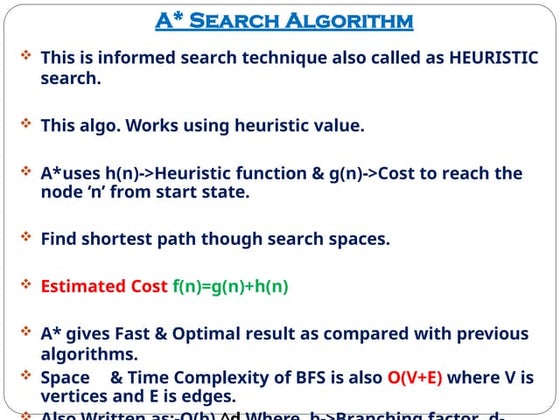

DS, ADT, Algorithms, Asymptotic Notations are summarized. A Star Algorithm in Artificial intelligence

A Star Algorithm in Artificial intelligencevipulkondekar

Ěý

A Star Algorithm in Artificial intelligenceESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3prasadmutkule1

Ěý

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3Common Network Architecture:X.25 Networks, Ethernet (Standard and Fast): fram...

Common Network Architecture:X.25 Networks, Ethernet (Standard and Fast): fram...SnehPrasad2

Ěý

X.25 Networks, Ethernet (Standard and Fast): frame format and specifications, Wireless LAN’s – 802.11x, 802.3 Bluetooth etc.

Cloud Cost Optimization for GCP, AWS, Azure

Cloud Cost Optimization for GCP, AWS, Azurevinothsk19

Ěý

Reduce Cloud Waste across AWS, GCP, Azure and Optimize Cloud Cost with a structured approach and improve your bottomline or profitability. Decide whether you want to outsource or manage it in house. Aboveground Fuel Storage Tanks

- 1. Term Project Report on ABOVEGROUND FUEL STORAGE TANKS Prepared by: Subkhiddin MUKHIDINOV Submitted to: Prof. Ĺžafak YILMAZ ISTANBUL TECHNICAL UNIVERSITY School of Mechanical Engineering

- 2. FUEL STORAGE TANKS INTRODUCTION Storage tanks operate under no pressure, distinguishing them from pressure vessels. Storage tanks are often cylindrical in shape, perpendicular to the ground with flat bottoms, and a fixed or floating roof. There are usually many environmental regulations applied to the design and operation of storage tanks, often depending on the nature of the fluid contained within. Above ground storage tanks differ from underground storage tanks in the kinds of regulations that are applied. Storage tanks are available in many shapes: vertical and horizontal cylindrical; open top and closed top; flat bottom, cone bottom, slope bottom and dish bottom. Large tanks tend to be vertical cylindrical, or to have rounded corners transition

- 3. from vertical side wall to bottom profile, to easier withstand hydraulic hydrostatically induced pressure of contained liquid. Most container tanks for handling liquids during transportation are designed to handle varying degrees of pressure. DESCRIPTION A fuel tank (or petrol tank) is a safe container for flammable fluids. Though any storage tank for fuel may be so called, the term is typically applied to part of an engine system in which the fuel is stored and propelled or released into an engine. Fuel tanks range in size and complexity from the small plastic tank of a butanelighter to the multi- chambered cryogenic Space Shuttle external tank.

- 4. USAGE Typically, a fuel tank must allow or provide the following: ď‚· Storage of fuel: the system must contain a given quantity of fuel and must avoid leakage and limit evaporative emissions. ď‚· Filling: the fuel tank must be filled in a secure way, without sparks. ď‚· Provide a method for determining level of fuel in tank, gauging (the remaining quantity of fuel in the tank must be measured or evaluated). ď‚· Venting (if over-pressure is not allowed, the fuel vapors must be managed through valves). ď‚· Feeding of the engine. ď‚· Anticipate potentials for damage and provide safe survival potential. Plastic (high-density polyethylene HDPE) as a fuel tank material of construction, while functionally viable in the short term, has a long term potential to become saturated as fuels such as diesel and gasoline permeate the HDPE material. Considering the inertia and kinetic energy of fuel in a plastic tank being transported by a vehicle, environmental stress cracking is a definite potential. The flammability of fuel makes stress cracking a possible cause of catastrophic failure. Emergencies aside, HDPE plastic is suitable for short term storage of diesel and gasoline. In the U.S.,Underwriters Laboratories approved tanks would be a minimum design consideration.

- 5. DESIGN Important considerations in designing a diesel fuel tank are determining placement, choosing the shape and calculating the required volume. Side mounting is the most common placement of diesel tanks for trucks. This is typically accomplished with the use of brackets, straps or a combination of both for the purpose of attaching the fuel tank to the truck frame. The choice of shape is generally influenced by the need for maximum fuel capacity and the desire for a stylish look. The most common diesel tank designs are cylindrical, rectangular and D-Style tanks. Cylindrical designs are often selected for their visual appeal while the rectangular tank is most often employed to maximize fuel volume for a given space. The D-Tank, as its name implies, is actually a hybrid of the cylindrical and rectangular designs. It offers the curved visual appeal of a cylindrical tank with significantly more fuel volume. Replacing a cylindrical fuel tank with a D-Tank can result in 46% additional fuel capacity. When calculating volume requirements, one would begin by assessing the available space. Once length, width and height restrictions have been ascertained, the easiest method of determining volume is with the use of a truck tank volume calculator. Although basic mathematics can be applied to calculate the volume of a cylinder, calculating that of a rectangular tank is more complex due to the rounded corners. Designers must take into consideration the loss of volume due to the radius of rounded corners.

- 6. MATERIALS Material selection is one of the key considerations in producing fuel tanks. The three most common materials used in the manufacture of fuel tanks are aluminum, steel and stainless steel. Regardless of the choice of material, the quality of the selection must be such as to allow that material to be malleable enough to be bent, rolled and stamped into formation. Aluminum alloy 5052 H32 is a popular choice for fuel tanks as it contains adequate magnesium content to allow the material to be pliable enough to meet the needs of the manufacturing process. The majority of diesel tanks manufactured today are made of steel; however truck operators may elect to choose aluminum fuel tanks when replacing older tanks on their vehicles. Aluminum offers advantages of lighter weight and resistance to corrosion. The selection of steel and stainless steel should be that of prime grade material. An important consideration in manufacturing is choosing material suitable for stamping and bending. The material must be ductile enough to be bent and formed yet thick enough to provide strength and to accept a weld. This is especially true for tanks of a design that require sharp bends.

- 7. MANUFACTURING While most tanks are manufactured, some fuel tanks are still fabricated by metal craftsmen or hand-made in the case of bladder-style tanks. These include custom and restoration tanks for automotive,aircraft, motorcycles, and even tractors. Construction of fuel tanks follows a series of specific steps. The craftsman generally creates a mockup to determine the accurate size and shape of the tank, usually out of foam board. Next, design issues that affect the structure of the tank are addressed - such as where the outlet, drain, fluid level indicator, seams, and baffles go. Then the craftsmen must determine the thickness, temper and alloy of the sheet he will use to make the tank. After the sheet is cut to the shapes needed, various pieces are bent to create the basic shell and/or ends and baffles for the tank. Many fuel tanks' baffles (particularly in aircraft and racecars) contain lightening holes. These flanged holes serve two purposes, they reduce the weight of the tank while adding strength to the baffles. Toward the end of construction, openings are added for the filler neck, fuel pickup, drain, and fuel-level sending unit. Sometimes these holes are created on the flat shell, other times they are added at the end of the fabrication process. Baffles and ends can be riveted into place. The heads of the rivets are frequently brazed or soldered to prevent tank leaks. Ends can then be hemmed in and soldered, or flanged and brazed (and/or sealed with an epoxy-type sealant) or the ends can be flanged and then welded. Once the soldering, brazing or welding is complete, the fuel tank is leak-tested.