Bioreactors in fermentation technology .pptx

- 1. BIOREACTORS

- 2. o Bioreactor ŌĆō can be described as a vessel which has provision of cell cultivation under sterile condition & control of environmental conditions e.g., pH, Temperature, Dissolved oxygen etc. o It could also be defined as an engineered device designed for optimal growth and metabolic activity of the organism through the action of biocatalyst, enzyme or microorganisms and cells of animal or plants. o It can be used for the cultivation of microbial plant or animal cells. o This process can either be aerobic or anaerobic. o The bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel.

- 3. o The sizes of the bioreactor can vary widely from the microbial cell (few mm3) to shake flask (100-1000 ml) to laboratory scale fermenter (1 ŌĆō 50 L) to pilot level (0.3 ŌĆō 10 m3) to plant scale (2 ŌĆō 500 m3) for large volume industrial applications. o There are several aspects of biotechnological processes, which require special attention in designing a bioreactor. o The reaction rate, cell growth, and process stability depend on the environmental conditions in the bioreactor. o The bioreactor's conditions like gas (i.e. air, oxygen, nitrogen, carbon dioxide) flow rates, temperature, pH and dissolved oxygen levels and agitation speed/circulation rate, foam production, etc. need to be closely monitored and controlled.

- 4. Bioreactor Design and Operations

- 5. ŌĆó A good bioreactor design should address improved productivity, validation of desired parameters towards obtaining consistent and higher quality products in a cost effective manner. ŌĆó The design and mode of operation of a bioreactor depends on the production of organism, optimum conditions required for desired product formation, product value and its scale of production. ŌĆó The effective bioreactor is to control and positively influence the biological reaction and must prevent foreign contamination.

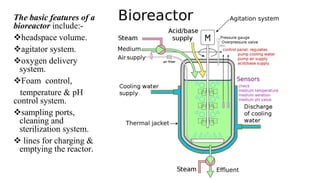

- 6. The basic features of a bioreactor include:- ’üČheadspace volume. ’üČagitator system. ’üČoxygen delivery system. ’üČFoam control, temperature & pH control system. ’üČsampling ports, cleaning and sterilization system. ’üČ lines for charging & emptying the reactor.

- 7. ’ü▒Headspace volume: The working volume of a bioreactor is the fraction of its total volume taken up by the medium, microbes, and gas bubbles and remaining volume is called the headspace. Generally, the working volume will be ~70-80% of the total reactor volume. This, however, depends on the rate of foam formation during the reaction. ’ü▒Agitator system consists of an external power drive, impeller and the baffles for intense mixing and increased mass transfer rates through the bulk liquid and bubble boundary layers. It provides enough shear conditions required for breaking up of bubbles. Most microbial fermentations use a Rushton turbine type impeller. ’ü▒Air delivery system consists of a compressor, inlet air, sterilization system and exit air sterilization system to avoid contamination. ’ü▒Foam control system is an essential element of bioreactor as excessive foam formation leads to blocked air exit filters and builds up pressure in the reactor. ’ü▒Temperature control system involves temperature probes, heat transfer system (jacket, coil). Heating is provided by electric heaters and steam generated in boilers and cooling is provided by cooling water produced by cooling towers or refrigerants such as ammonia.

- 8. ’ü▒pH control system uses neutralizing agents to control pH; these should be noncorrosive, non-toxic to cells when diluted in the medium. Sodium carbonate is commonly used in small scale bioreactor. ’ü▒Sampling ports are used to inject nutrients, water, salts etc. in bioreactors and also for collecting samples. ’ü▒Cleaning and sterilization system is important to avoid contamination. Thermal sterilization by steam is preferred option for economical and large-scale sterilizations of equipment. Sterilization by chemical substances is generally preferred for heat-sensitive equipment. Sterilization is carried out by radiation by UV for surfaces and x-rays for liquids and also by membrane filters having uniform microspores and depth filters with glass wool. ’ü▒Charging & emptying lines are used for input of reactants and withdrawal of products in the bioreactor.

- 9. To achieve optimization of the bioreactor system, the following operating guidelines must be closely adhered to: 1. The bioreactor should be designed to exclude entrance of contaminating organisms as well as containing the desired organisms 2. The culture volume should remain constant, i.e. no leakage or evaporation 3. The dissolved oxygen level must be maintained above critical levels of aeration and culture agitation for aerobic organisms 4. Environmental parameters such as temperature, pH, etc., must be controlled and the culture volume must be well mixed.

- 11. TYPES OF BIOREACTOR ŌĆó There are mainly three types of reactions involved in fermentation process i.e. batch, continuous and semi-continuous or fed-batch depending on the feeding strategy of the culture and the medium into the bioreactor. ŌĆó Traditional batch stirred tank reactors (STRs) and continuously stirred tank reactors (CSTRs) have existed for centuries and are still widely adopted in the chemical and bioprocessing industry for production due to their simplicity. ŌĆó Other bioreactors, which have special design and operational attributes are photo-bioreactors, rotary drum reactors, mist bioreactor, membrane bioreactor, packed & fluidized bed bioreactors, bubble column & air lift bioreactors etc. These have been developed to application specific processes.

- 12. Batch Process ŌĆó In the batch process, after sterilization, the sterile culture medium is inoculated with microorganisms. During this reaction period, cells, substrates including the nutrient salts, vitamins and concentrations of the products vary with time. The fermentation is allowed to run for a predetermined time and the product is harvested at the end. To promote aerobic cultivation, the medium is aerated to provide a continuous flow of oxygen. Gaseous by- products such as CO2 are removed.

- 13. Lag phase: The growth of microbial population when it is inoculated with a fresh medium starts after a certain period of time called lag phase Log or Exponential phase: In this phase, the microbial cell numbers double per unit time period. When the cell number from such a reaction is plotted on logarithmic scale as function of elapsed time, a curve is obtained with a constantly increasing slope. Stationary phase: In stationary phase there is no increase or reduction in cell number. The cell functions such as energy metabolism and some biosynthetic processes go on. Death phase: The cells may start dying if the incubation is continued after the bacterial population arrive the stationary phase. Cells may die due to cell lysis, which is a much slower process than the growth phase.

- 14. Continuous Process ŌĆó For a bioreactor on continuous mode operations, fresh medium is continuously added and the products, along with the culture are removed at the same rate, thus maintaining constant concentrations of nutrients and cells throughout the process. Continuous process is frequently used for high-volume production; for reactions using gas, liquid or soluble solid substrates; and for processes involving microorganisms with high mutation- stability. Typical end products include vinegar, baker's yeast and treated wastewater. Chemostat is a common example of continuous process reactor.

- 15. Semi-continuous or Fed-batch Process ŌĆó The process uses a combination of batch and continuous reactions. In this process additional nutrients are added progressively to the reactor as the bioreactions are underway so as to obtain better yields and higher selectivity along with controlling the reaction temperature. The products are harvested at the end of the production cycle as in a batch bioreactor. Semi-batch reactors are stabler and perform safer operations than in a batch reactor.

- 17. Packed Bed Bioreactors A bed of solid particles, with biocatalysts on or within the matrix of solids, packed in a column constitutes a packed bed bioreactor (Fig. 19.3B). The solids used may be porous or non-porous gels, and they may be compressible or rigid in nature. A nutrient broth flows continuously over the immobilised biocatalyst. The products obtained in the packed bed bioreactor are released into the fluid and removed. While the flow of the fluid can be upward or downward, down flow under gravity is preferred. The concentration of the nutrients (and therefore the products formed) can be increased by increasing the flow rate of the nutrient broth. Because of poor mixing, it is rather difficult to control the pH of packed bed bioreactors by the addition of acid or alkali. However, these bioreactors are preferred for bioprocessing technology involving product- inhibited reactions. The packed bed bioreactors do not allow accumulation of the products to any significant extent.

- 19. Fluidized Bed Bioreactors Fluidized bed bioreactor is comparable to bubble column bioreactor except the top position is expanded to reduce the velocity of the fluid. The design of the fluidized bioreactors (expanded top and narrow reaction column) is such that the solids are retained in the reactor while the liquid flows out. These bioreactors are suitable for use to carry out reactions involving fluid suspended biocatalysts such as immobilized enzymes, immobilized cells, and microbial flocs. For an efficient operation of fluidized beds, gas is spared to create a suitable gas-liquid-solid fluid bed. It is also necessary to ensure that the suspended solid particles are not too light or too dense (too light ones may float whereas to dense ones may settle at the bottom), and they are in a good suspended state. Recycling of the liquid is important to maintain continuous contact between the reaction contents and biocatalysts. This enable good efficiency of bioprocessing

- 21. Continuous Stirred Tank Bioreactors A continuous stirred tank bioreactor consists of a cylindrical vessel with motor driven central shaft that supports one or more agitators (impellers). The shaft is fitted at the bottom of the bioreactor. The number of impellers is variable and depends on the size of the bioreactor i.e., height to diameter ratio, referred to as aspect ratio. The aspect ratio of a stirred tank bioreactor is usually between 3-5. However, for animal cell culture applications, the aspect ratio is less than 2. The diameter of the impeller is usually 1/3 rd of the vessel diameter. The distance between two impellers is approximately 1.2 impeller diameter. Different types of impellers (Rustom disc, concave bladed, marine propeller etc.) are in use. In stirred tank bioreactors or in short stirred tank reactors (STRs), the air is added to the culture medium under pressure through a device called sparger. The sparger may be a ring with many holes or a tube with a single orifice. The sparger along with impellers (agitators) enables better gas distribution system throughout the vessel. The bubbles generated by sparger are broken down to smaller ones by impellers and dispersed throughout the medium. This enables the creation of a uniform and homogeneous environment throughout the bioreactor.