Mpfi (Multipoint Fuel Injection)

- 1. ANJAL PATEL FINAL B.E. MECHANICAL S.V.I.T. VASAD. PRESENTS

- 2. MULTI-POINT FUEL INJECTION { M.P.F.I }

- 3. OVERVIEW INTRODUCTION PURPOSE OF THE FUEL SYSTEM CLASSIFICATION OF MPFI MULTIPOINT FUEL INJECTION STAGES COMPONENTS FUEL INJECTION ADVANTAGES FUEL DELIVERY SYSTEM FUEL INJECTTION SERVICE

- 4. CLASSIFICATION OF FUEL INTAKE SYSTEMS FUEL INTAKE SYSTEMS FUEL INJECTON CARBURATOR SYSTEMS THROTTLE BODY MULTI-POINT IGNITION (TBI) INJECTION (MPFI)

- 5. DEFINTION AND COMPONENTS ŌĆó DEFINITON: ŌĆó M.P.F.I: stands of multi-point fuel injection system wherein fuel is injected into individual cylinders based on commands from the ŌĆśon board engine management system computerŌĆÖ ŌĆō popularly known as the Engine Control Unit (ECU). ŌĆó COMPONENTS: ŌĆó FUEL TANK ŌĆó FUEL PUMP ŌĆó FUEL FILTER ŌĆó INJECTORS ŌĆó INTAKE MANIFOLD ŌĆó FUEL LINES ŌĆó ENGINE CONTROL UNIT (ECU) ŌĆó RELAY SYSTEMS

- 6. CLASSIFICATION OF MPFI SYTEM M.P.F.I SEQUENTIAL SIMULTANEOUS GROUP (Direct injection into (together for all the four (into cylinder- Individual cylinders or what ever the number of pairs) Against their suction Cylinders) Strokes) Examples: SEQUENTIAL: ford icon, hundai, maruti, SIMULTANEOUSGORUP: cielo, matiz SINGLE POINT INJECTION: older opel astra

- 7. STAGES ( I & II)

- 8. STAGE ( III & IV)

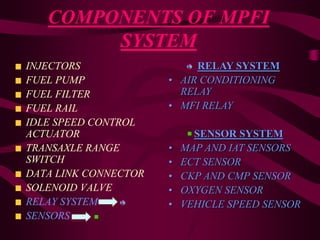

- 9. COMPONENTS OF MPFI SYSTEM INJECTORS RELAY SYSTEM FUEL PUMP ŌĆó AIR CONDITIONING FUEL FILTER RELAY FUEL RAIL ŌĆó MFI RELAY IDLE SPEED CONTROL ACTUATOR SENSOR SYSTEM TRANSAXLE RANGE ŌĆó MAP AND IAT SENSORS SWITCH ŌĆó ECT SENSOR DATA LINK CONNECTOR ŌĆó CKP AND CMP SENSOR SOLENOID VALVE ŌĆó OXYGEN SENSOR RELAY SYSTEM ŌĆó VEHICLE SPEED SENSOR SENSORS

- 10. FUEL INJECTORS ’āśThe ŌĆśFuel InjectorsŌĆÖ are precision built ŌĆśSolenoid ValvesŌĆÖ, something like Washing Machine Water inlet Valves. ’āś These have either single or multiple ŌĆśOrificesŌĆÖ which ŌĆśsprayŌĆÖ fuel into the Fuel inlet manifold of a Cylinder upon actuation, from a common Rail/Header pressurised to around 3 bar, fed by a high pressure electrically driven fuel pump inside the Petrol tank of the Car.

- 12. THROTTLE VALVE { PARTIALLY OPEN}

- 13. ENGINE CONTROL UNIT ŌĆó The ŌĆśon-boardŌĆÖ ECU primarily controls the Ignition Timing and quantity of fuel to be injected. The latter is achieved by means of controlling the ŌĆśdurationŌĆÖ for which the Injector solenoid valve coil is kept energized - popularly known as the ŌĆśpulse-widthŌĆÖ. ŌĆó In general, an ECU in turn is controlled by the ŌĆśdata inputŌĆÖ from a set of ŌĆśSENSORSŌĆÖ located all over the Engine and its Auxiliaries ŌĆó Based on a ŌĆśprogrammedŌĆÖ interpretation of all this input data, the ECU gives the various ŌĆścommandsŌĆÖ to the EngineŌĆÖs fuel intake and spark ignition timing systems, to deliver an overall satisfactory performance of the Engine from start to shut down, including ŌĆśemission controlŌĆÖ. SENSORS ŌĆó These detect the various ŌĆśoperating statesŌĆÖ of the Engine and the performance desired out of it. Such Sensors constantly monitor : 1) Ambient Temperature, 2) Engine Coolant Temp., 3) Exhaust/manifold temp., 4) Exhaust ŌĆśO2ŌĆÖ content, 5) Inlet manifold vacuum, 6) Throttle position, 7) Engine rpm, 8) Vehicle road speed, 9) Crankshaft position, 10) Camshaft position, etc.

- 14. COMPONENTS AND THEIR ASSEMBLY {fig}

- 15. BLOCK DIAGRAM OF SENSORS PROVIDING INFORMATION TO ECU ABSOLUTE MANIFOLD EGR SOLENOID PRESSURE FUEL ENGINE RPM PUMP ELECTRONIC COOLANT FAST-IDLE CONTROL TEMPERATURE VALVE UNIT INTAKE MANIFOLD GROUP-I AIR INJECTION TEMPERATURE VALVE GROUP-II THROTTLE POSITION INJECTION VALVE

- 16. FUEL INJECTION ŌĆó MPFI: Fuel injection is done in the intake manifold, individually in each of the cylinders ŌĆó TBI: Fuel injection is done slightly above each throat of the throttle body.

- 17. ADVANTAGES OF MPFI ŌĆó SOLVES THE PROBLEM OF THE CARBURETOR BY SUPPLING : a) SAME AMOUNT OF FUEL MIXTURE b) SAME FUEL- MIXTURE RICHNESS ŌĆó INTAKE MANIFOLD DOES NOT HAVE TO HANDEL FUEL BUT ONLY AIR ŌĆó HOOD HEIGHT OF THE CAR IS DECREADED AS ONLY A THROTTLE VALVE INSTEAD OF THE WHOLE CARBURETOR IS USED ŌĆó NO EXTRA HEATING DURING WARM-UP ŌĆó NO MANIFOLD HEAT-CONTROL VALVE OR HEATED-AIR SYSTEM REQUIRED ŌĆó THROTTLE RESPONSE IS FASTER BECAUSE THE FUEL IS UNDER PRESSURE WHEREAS A CARBURETOR DEPENDS ON THE DIFFERENCE IN AIR PRESSURE

- 18. ELECTRONIC FUEL INJECTION VARIOUS SENSORS: MANIFOLD ABSOLUTE PR. AMBIENT PRESSURE COOLANT TEMPERATURE AIR-FUEL MIXTURE TEMP. ENGINE SPEED THROTTLE POSITION OXYGEN

- 19. CADILLAC 1975-1978 PORT FUEL INJECTION ŌĆó THE IGNITION VALVES WERE CONNECTED TO A FUEL RAIL. ŌĆó THE NO. OF INJECTORS ARE DIVIDED INTO TWO GROUPS ŌĆó EACH GROUP IS TURNED ON ALTERNATIVELY BY THE ECU. ŌĆó THE INJECTION VALVES ARE TURNED ON ONCE FOR EACH TWO REVOLUTIONS OF CRANKSHAFT

- 20. THREE INJECTORS CONNECTED TO FUEL RAIL (fig)

- 21. FUEL-DELIVERY SYSTEM -FUEL PUMP -FUEL FILTER -INJECTION VALVE OPERATED BY SOLENOID SOLENOID-ECU-BATTERY -THE VALVES ARE ACTUATED IN GROUPS

- 22. IGNITION TIMING CHART FOR SIX- CYLINDER ENGINE 300 360 300 0 120 240 360 480 600 720 120 240 360 480 1 5 3 6 2 4 INTAKE VALVE START OF IGNITION OPENS INJECTION POINT

- 23. FUEL METERING BY MEASURING AIR FLOW 1. PIVOTED FLAP IS PLACED IN THE AIR PASSAGE 2. HOT-WIRE INDUCTION IS USED ----- THESE INSTRUMENTS GIVE INFORMATION TO THE ECU WHICH DETERMINES THE TIME FOR WHICH THE FUEL INJECTION HAS TO BE DONE

- 24. REFERENCES AUTOMOBILE MECHANICS ŌĆō CROUSE & ANGLIN WWW.RC.COM A TEXT BOOK ON AUTOMOBILE ENGINEERING BY T.R.BANGA, NATHU SINGH WWW.HOWSTUFFWORKS.COM