Lean sixsigmaasq0604

- 1. Variance Reduction International, Inc. Lean Six Sigma VarianceReduction.com (909) 484-2950

- 2. Lean Six Sigma Principles  Specify value in the eyes of the customer  Identify value stream; eliminate waste and variation  Make value flow at pull of the customer  Involve, Align & Empower Employees  Continuously improve knowledge in pursuit of perfection

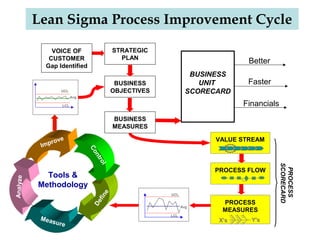

- 3. Lean Sigma Process Improvement Cycle VOICE OF STRATEGIC CUSTOMER PLAN Better Gap Identified BUSINESS BUSINESS UNIT Faster UCL OBJECTIVES SCORECARD Avg LCL Financials BUSINESS MEASURES r ove VALUE STREAM I mp Co nt ro SCORECARD l PROCESS FLOW PROCESS Tools & Analyze Methodology e UCL fin PROCESS De Avg MEASURES LCL M ea X's Y's sure

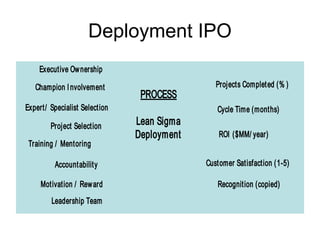

- 4. Deployment IPO Executive Ow nership Champion I nvolvement Projects Complet ed (% ) PROCESS Expert/ Specialist Selection Cycle Time (months) Project Selection Lean Sigma Deployment ROI ($MM/ year) Training / Mentoring Accountability Customer Satisfaction (1-5) Motivation / Rew ard Recognition (copied) Leadership Team

- 5. Supplier Better Material Type S y Yield Amount of A Temperature Design Type Six Sigma SOPs ry to In- CODN (Finance) en Process I nv Storag Results Communication Cost e Driven IPO P Team Dynamics Sp s roc Pr Diagram ac es od e uc Turnover t Rate Cell Layout Design Piece Flow t De hpu l) Lean ia Manpower er ug el ay at ro l (M Th Setup SOPs r Time bo av La Tr Maintenance SOPs Pr Se Ca Le ity Cell Cleanliness oc tup pa ad es c s

- 6. What is Lean and Six Sigma? • Lean, pioneered by Toyota, • Six Sigma, developed by focuses on the efficient Motorola, made famous by GE, operation of the entire value it can be defined as a: chain. – Measure of process • Focus areas: capability – Remove non-value added – Set of tools steps to: – Disciplined methodology • Reduce cycle time – Vision for quality • Improve quality – Philosophy – Align production with – Strategy demand. – Reduce inventory. – Improve process safety and efficiency. Lean Sigma is a combination of two powerful and proven process improvement methods Lean and Six Sigma, that builds on existing organization capability in quality, statistics, and project execution.

- 7. Lean Sigma: A Set of Tools Measurement System Analysis Glass Inspection Test Operator 1 Operator 2 Operator 3 Item Test 1 Test 2 Test 1 Test 2 Test 2 Test 1 Use control charts to Use control charts to 1 understand & identify understand & identify 2 3 common & special common & special 4 Map the process to Map the process to causes causes 5 determine where determine where 6 defects are being defects are being 7 Verify assessment/ created 8 Verify assessment/ created 9 measurement systems measurement systems 1 0 RISK PRIORITY NUMBER (RPN) = SEVERITY X 0CCURRENCEX ESCAPED DETECTION Score Run A B AB y y y ... y s Category 5 4 3 2 1 1 2 3 1 - - + Severity Severe High Moderate Minor Negligible (SEV) 2 - + - Occurrence Very High High Moderate Low Very Low 3 + - - (OCC) 4 + + + Document failure modes Document failure modes Designed experiments to Designed experiments to ∆ ∆ ∆ Escapedfor products andModerate Low Very Low for products andprocesses Very High High processes ˆ make process robust 2to A • B y = y + A A + B B + AB Detection (DET) to identify defects' root cause make process robust to 2 2 to identify defects' root cause variation variation ˆ δ δ δ s = s + ¯ A A + B B + AB A • B 2 2 2

- 8. How is Lean Sigma different and similar to past quality and statistical efforts? • Sponsored and directed by • Uses many tools already leadership familiar to many people – • Aligned with business fishbone, process flow, objectives and tactics SPC, brainstorming • Focused on delivering • Aligned with quality efforts business results • Uses a logical problem • Track record for delivering solving approach that will business results • Disciplined and systematic not be new to some execution process • Aligned with past quality • Brings in new tools to most and reliability efforts – companies – DOE, TQM, Baldrige, Deming hypothesis testing, FMEA, Kanbans, PokaYoke

- 9. Focus Area of Lean and Six Sigma Lean: • Reduction of the “7 hidden wastes” or non-value added activities to reduce cycle time. Six Sigma: • Reduction of variability to improve quality. Both Lean and Six Sigma Tie Improvements to $$$

- 10. Overlap of Lean and Six Sigma Tools Cycle Time Reduction Variance Reduction Mapping IPO Logical CE JIT Physical • PF CNX Time • Scorecard Testing Quick • SOP Correlations Changeovers • Mistake Hypothesis Single Piece Proofing DOE Flow 5Ss • $$$ Visual FMEA Lean Controls MSA Six Sigma

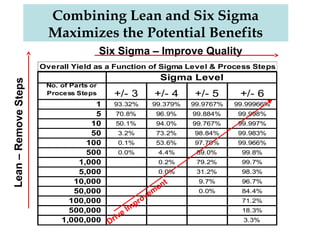

- 11. Combining Lean and Six Sigma Maximizes the Potential Benefits Six Sigma – Improve Quality Overall Yield as a Function of Sigma Level & Process Steps Sigma Level Lean – Remove Steps No. of Parts or Process Steps +/- 3 +/- 4 +/- 5 +/- 6 1 93.32% 99.379% 99.9767% 99.99966% 5 70.8% 96.9% 99.884% 99.998% 10 50.1% 94.0% 99.767% 99.997% 50 3.2% 73.2% 98.84% 99.983% 100 0.1% 53.6% 97.70% 99.966% 500 0.0% 4.4% 89.0% 99.8% 1,000 0.2% 79.2% 99.7% 5,000 0.0% 31.2% 98.3% 10,000 t 9.7% 96.7% en 50,000 m 0.0% 84.4% ove 100,000 pr 71.2% 500,000 e Im 18.3% 1,000,000 Driv 3.3%

- 12. Sigma Capability The number of Sigmas between the center of a process and the nearest specification limit 3 σ Process Centered 3 σ Process • We make more than Lower Upper customer needs because Specification Specification some of what we make Limit Limit is waste • Process is WIDER than the specifications Determined by Determined by the customer the customer WASTE -6σ -5σ -4σ -3σ -2σ -1σ 0 +1σ +2σ +3σ +4σ +5σ +6σ 6 σ Process 3 σ Process has 66,807 6 σ Process Centered dpm vs 3.4 from a 6 σ • We make as much as process the customer needs and have very little waste • Process FITS within the specifications -6σ -5σ -4σ -3σ -2σ -1σ 0 +1σ+2σ+3σ+4σ+5σ+6σ

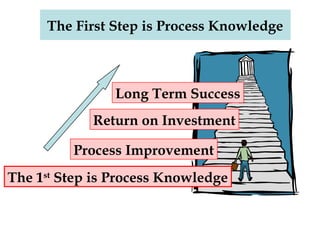

- 13. The First Step is Process Knowledge Long Term Success Return on Investment Process Improvement The 1st Step is Process Knowledge

- 14. 80 Percent of the Gain with 20 Percent of the Complexity Most of the 80% improvement is possible with Improvement the basic quality and statistical tools. 20% Tool Complexity

- 15. Sustained Improvements without Capital Dollars •Sustainable Results •Process improvements from Lean Sigma Projects are sustained. •Typically, results are audited at 4 and 12 months after implementing changes. •Not Capital Driven •Lean Sigma projects are NOT Capital driven. •Most improvements are made by changes in the SOP.

- 16. Lean Six Sigma Roadmap DMAIC Strategy • Define – Identify and Prioritize Opportunities – Select Your Project – Define the Goals and Objectives – Form Cross functional Team – Understand Customer Requirements • Measure – Define and Analyze the Current Process – Assess the Capability of the Measurement Process – Assess the Current Capability of the Process – Variance Reduction

- 17. DMAIC Cont. • Analyze – Identify the Key Input Variables – Discover the Relationship between the Inputs and Outputs – Identify the Root Causes of the Problems • Improve – Identify and Test the Proposed Solutions – Re-assess Capability – Implement Solution • Control – Document Results and Return on Investment – Take Actions to Hold the Gains – Celebrate and Communicate

- 18. Variance Reduction International, Inc. President, Sally Ulman Mary Ann “Sally” Ulman teaches and consults on the subject of applications of statistical methods. She is an experienced facilitator in the areas of team building, problem solving, metric development, and implementation of process improvement strategies. Ms. Ulman left Chevron, USA after sixteen years where she worked as a Quality Facilitator, Corrosion Engineer, and Industrial Water Treatment Technologist throughout Central California and Sumatra, Indonesia. She has taught and consulted for Chevron, Caltex Pacific Indonesia, GlaxoWellcome in Pakistan, GlaxoSmithKline in Bangkok, Kuala Lumpur, London, Jakarta and India, Texaco, Baker Petrolite, Aera Energy, National Association of Corrosion Engineers, Farwest Corrosion, Mazda USA, Teac America, American Business Communications, California Training Cooperative, Auto Meter, PLCs Plus, United Way Agencies and various public seminars. Her extensive consulting background involves industrial and service applications of DOE, SPC, LeanSigma, reliability, management and team building techniques. She received her B.A. in Physical Education from California State University, Northridge. She attained Six Sigma Black Belt certification from University of Texas and Master Black Belt certification from Air Academy Associates. In addition she also holds a California Junior College Teaching Credential, Corrosion Technologist and Coating Inspection Certification from the National Association of Corrosion Engineers. She is now President of Variance Reduction International Inc. and works as an instructor and consultant for Air Academy Associates and is the Six Sigma instructor at San Diego State University.

Editor's Notes

- #10: Lean has traditionally focused on cycle time reduction, inventory reduction, reduction of floor space, by the elimination of the 7 hidden wastes. Six Sigma has traditionally focuses on variance reduction (the elimination of “noise factors”) to improve quality. The goal of both is to produce a financial benefit.

- #11: This graphic summarizes the tools have been traditionally used for Cycle Time Reduction (Lean) and for Variance Reduction / Quality Improvement (Six Sigma) and which ones are common to both.

- #12: The point of this table is to illustrate that a process can be improved by reducing steps (Lean) and-or increasing quality (Six Sigma) of each step. For example, a 10 step process with a 3 sigma quality level will only produce products with a 50% yield (the probability that a good part will be produced each time a new one is started through the process). The combination of Lean and Six Sigma provides the best possible result. It is suggested that steps be eliminated before efforts are made to improve quality of each step.

- #14: The first step in process improvement is to gain process knowledge. Without this step we can stumble. True understanding of our processes is a competitive advantage.

- #15: Major process improvement can be made with the basic quality and statistical tools. Only after the process is operating at high performance do we need to employ more sophisticated knowledge gaining tools.

- #16: The look backs performed at 12-months have repeatedly demonstrated that improvements are sustained. The improvements are typically made by changes in procedures. The only money spent on Lean Sigma projects is typically for collecting data. The investment is the time the team takes to understand the process, collect and analyze the data, and implement the changes.