Grounding and techniques

- 2. 2

- 3. ï A conducting connection, whether intentional or accidental, between an electrical circuit or equipment and the earth, or to some conducting body that serves in place of earth. ï Ground is a connection to Earth made either intentionally or accidentally. 3

- 4. 4

- 5. 5 NEED OF GROUNDING: ï To protect people and equipment from dissipating stray energy from: 1. Electrical faults (fuses, breakers etc.) 2. Lightning strikes 3. Radio Frequency 4. Static discharges

- 6. 6

- 7. 7 Electrical installations which need grounding: ïThe frames, tanks and enclosures of electric machines, transformers and apparatus, lightning fittings and so on. ïOperating mechanism of the switchgear. ïFramework of the switchboards, control boards, individual panel boards. ïStructural steelwork of indoor & outdoor substations, metal cable jointing boxes, metal sheaths of cables & similar metal works .

- 8. 8 Losses due to improper grounding: ï Estimation of at least 15% of power quality problems are related to grounding. ï Lightning strikes on equipment with poorly maintained protection systems destroy millions of dollars of equipment and lost production every year. ï Electric shocks, vibrations & noise from electronic devices due to improper wiring, also leads to mankind loss also.

- 9. 9 Types of grounding systems: Different methods are available but the choice depends on local conditions and required function. Thus, we can see basically four types: 1. Single stake 2. Ground rod group 3. Ground plate 4. Ground mesh

- 10. 10 1. Single stake: ïThe simplest form of grounding element is the ground stake, this can take many forms with a variety of lengths from a few feet to many feet long made of materials such as brass, galvanised or stainless steel, the size and material as required locally ïThe simple ground rod can be used for lightning protection on stand-alone structures such as pole mounted transformers or radio towers, it can also be used as a back up to a utility ground.

- 11. 11 Single stake

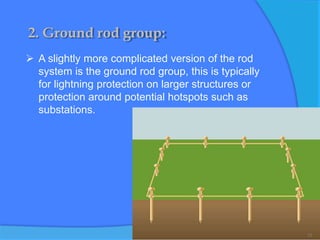

- 12. 12 2. Ground rod group: ï A slightly more complicated version of the rod system is the ground rod group, this is typically for lightning protection on larger structures or protection around potential hotspots such as substations.

- 13. 13 3. Ground plate: ïGround plates are used widely in telecoms applciations. They are particularly good where the deeper ground has high resistivity. ïFor areas where there is rock (or other poor conducting material) fairly close to the surface ground plates are preferred as they are more effective

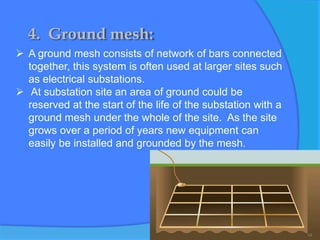

- 14. 14 4. Ground mesh: ï A ground mesh consists of network of bars connected together, this system is often used at larger sites such as electrical substations. ï At substation site an area of ground could be reserved at the start of the life of the substation with a ground mesh under the whole of the site. As the site grows over a period of years new equipment can easily be installed and grounded by the mesh.

- 15. 15 Ground mesh

- 17. 17 Steps involved: 1. Before grounding one has to know the resistivity strength of the land or soil of the place. 2. Grounding tests are performed to know the influence of spheres of influences. 3. Selection for type of grounding needed at the place. 4. Grounding tests to know the depth and wide range grounding needed for the site based on type of devices or equipments used as loads.

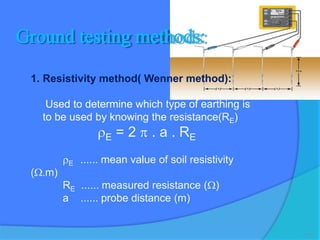

- 18. 18 Ground testing methods: 1. Resistivity method( Wenner method): Used to determine which type of earthing is to be used by knowing the resistance(RE) ïēE = 2 ï° . a . RE ïēE ...... mean value of soil resistivity (W.m) RE ...... measured resistance (W) a ...... probe distance (m)

- 19. 19 2. Fall of potential testing( Three or Four pole method): ï Most commonly used method of testing. ï Three or four pole method, this refers to the number of connections made to the ground tester. ï The forth pole of the connection is made if the wire to connect to the system under test is particularly long >> 4 meters. The additional wire cancels out an error due to the extended length of wire used.

- 20. 20 3. Selective measurement method: ï The selective method is based on the Fall of Potential test. ï A current clamp is used to isolate the test current injected into the electrodes under test, the current will flow to earth by any path.

- 21. 21 4. The stake less method: ï Eliminates the need for temporary ground stakes. ï This is useful in a wide range of situations. Eg: Inside buildings Airports Urban locations Chemical and industrial plant ï The temporary ground stakes are replaced by two current clamps. The first clamp generates a voltage on the ground condutor, the second clamp measures the current flowing due to the generated voltage.

- 22. 22 5. Two pole method: ï Used where other methods are not available. ï Uses nearby metal structures as a temporary spike. ï Metal water pipes are typically used Drawbacks: ï The resistance of the metal pipe should be significantly less than the electrode under test. ï Metal pipes are being replaced with plastic. ï Some metal pipes use plastic couplings.

- 23. 23

- 24. 24

- 25. 25 SUMMARY: ï Following Proper grounding methods decreases the electrical faults. ï Improper grounding, no grounding for a plant or substation or house are to be avoided. ï Get known resistivity of the land suitable method of grounding is to be employed. ï Proper grounding is the sign of effective working of equipment.

- 26. 26

- 27. 27

- 28. 28

Editor's Notes

- #4: Ground is nothing but a connection between a conductor to ground. Usually a current takes the path of low resistance so one has to setup a low resistance path for a place or a electrical or electronic system is setup known as a grounding system.

- #5: This is a simple picture of a ground.

- #6: Thus due to electrical faults at the time of lightening faulty currents try to flow through a low resistive path creating a contact with the earth. When there is no proper grounding in such times those surge currents may also choose human body as a path to ground as a human body has resistance lower than an electrical system and easy way to reach earth.

- #7: These are some examples of improper grounding on metal works and jointings.

- #8: Parts of electrical systems which need grounding are displayed here. We can see that many of the electrical equipments need grounding else due to improper connections or wiring may lead to flow of faulty currents through the body frame work that may be harmful to person who touch or besides thus causing electrical shock.

- #10: But before taking a step of grounding one has to know the type of grounding needed for a place. So, first we discuss about the grounding methods we usually apply in many cases. These grounding systems are of four kinds.

- #19: We use four stakes in this method . Where we inject current through two stakes and measure the resistance using other two stakes. And by substituting that resistance in above formula we can calculate the resistivity.

- #20: With this method, two test spikes are used and either one or two connections made to the ground under test. The forth pole of the connection is made if the wire to connect to the system under test is particularly long >12 feet.

- #22: Fluke 1623 and fluke 1650 are the examples of instruments used for stake less method.