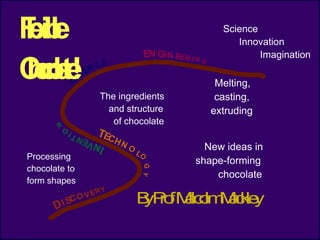

Chocolate lecture abingdon school-2010

- 1. Fxle leib Science Innovation EN GI N EE R I N Imagination Ccla! h ot o e G E NC IE SC Melting, The ingredients casting, and structure extruding of chocolate N O TI TEC N E HN IN V O L New ideas in Processing shape-forming O chocolate to G Y chocolate form shapes RY O VE B P fMlc lm ak y y r a o Mcle o D I SC

- 2. Fellow of Robinson College

- 3. Professor of Process Innovation Department of Chemical Engineering and Biotechnology University of Cambridge

- 4. 1965 O Levels; Gravesend Technical High School 1967 A Levels; Bath Technical College 1969 BSc Physics; Leicester University 1972 PhD; Polymer Physics; Bristol University 1976 Lecturer in Material Science; University of Sussex 1979 Department of Chemical Engineering, University of Cambridge 1994 Chocolate

- 5. The scientific mind R ’Ż½ YB ’ŻČ ’Ż½ 1 ’ŻČ LB = ’Ż¼ ’ŻĘ ’Ż¼ 2 ŌłÆ 1’ŻĘ 2 ’ŻŁ Žäw ’ŻĖ ’ŻŁ X ’ŻĖ

- 6. The inventive mind The Patent Self-Operating Napkin

- 10. C ocoa pods

- 12. Structure of chocolate Cocoa butter Sugar crystals Cocoa solids Milk solids about 0.1 mm

- 13. Cocoa butter - melted

- 14. Cocoa butter - solid

- 15. Melting Chocolate 100 liquid 80 60 solid soft Proportion of 40 fat that is liquid 20 hard solid ( percent ) 0 -10 0 10 20 30 40 50 Temperature of chocolate (degrees.C )

- 16. Traditional chocolate forming i mxing ixin heating to about 400C pouri cooling tunnels from300C to 180C ng eating! de-moulding The chocolate m be heated ust to m the fat so that it elt can be poured into moulds. It m then be cooled to about 18oC ust before it can be removed fromthe mould. The whole process takes about thirty minutes.

- 17. Extrusion processing Polyethylene Cold Melt Extrusion Processing ŌłåH 50 100 150 200 Temperature 0C Chocolate Cold Melt Extrusion Processing ŌłåH 10 20 30 40 0 Temperature C

- 19. Extrusion process Go to movie on chocolate cold extrusion process

- 20. knotting Go to movie on Chocolate cold extrusion knotting

- 21. moulding Go to movie on chocolate cold extrusion moulding

- 22. Extruding a tube extrusion "torpedo"

- 27. Axisymmetric ram experiments U D0 / 2 pressure transducer pressure ╬▒ end of D/2 piston motion L time

- 28. Cold extrusion of semi solid chocolate Typical Pressure v/s Time trace Piston/(ram) A Yield pressure Chocolate feed Pressure transducer Die ŌłåP (bar) B Extrusion pressure C Compaction (no flow) Milk choc at 20 oC t (s)

- 30. 15 Ex trusion 10 Pre ssure M Pa 5 0 10 15 20 25 30 Te mp e rature 0C

- 31. Mechanism. Rate of doing work = Rate of heat generation P A x = Žü A x Cp Ōłå T ’Ć” ’Ć” PA = pressure x area = force x ’Ć” = velocity Žü = density Cp = Specific heat ŌłåT = temperature increase P ŌłåT = Žü Cp 100 10 5 ŌłåT = = 6.9 0C 1, 200 1,200

- 32. Temperature doesnŌĆÖt change! So where does the work go?

- 33. Another calculation P Ax P ’Ć” Rate of work done/kg = = Žü Ax Žü ’Ć” Work done/kg in melting mass fraction Žå of cocoa butter =Žå╬╗ ╬╗ = latent heat of melting / kg Equate P =Žå╬╗ Žü P 10 7 Žå= = 3 = 5.5% Žü╬╗ 1,200x150x10

- 34. 100 % Liquid Fat 50 Microstructure change adiab atic heating 0 10 20 30 T e m pe ra ture Centigrade /

- 35. The mechanism 1: Before flow Liquid fat in isolated sub- micron regions Sugar crystals

- 36. The mechanism 2: As flow begins Sub-micron internal ŌĆ£slip planesŌĆØ allow plastic flow. Some crystals melt Some fat migrates to walls, reducing friction and easing flow

- 37. The mechanism 3: During flow Liquid fat slip planes make the chocolate flexible

- 38. The mechanism 4: Some time later.... As liquid fat reverts to its original regions and cocoa butter recrytallises, so the chocolate hardens

- 40. The scientific mind R ’Ż½ YB ’ŻČ ’Ż½ 1 ’ŻČ LB = ’Ż¼ ’ŻĘ ’Ż¼ 2 ŌłÆ 1’ŻĘ 2 ’ŻŁ Žäw ’ŻĖ ’ŻŁ X ’ŻĖ

- 41. The inventive mind The Patent Self-Operating Napkin