PRINCIPALELE Coduri G&M FANUC FREZE HAAS.pdf

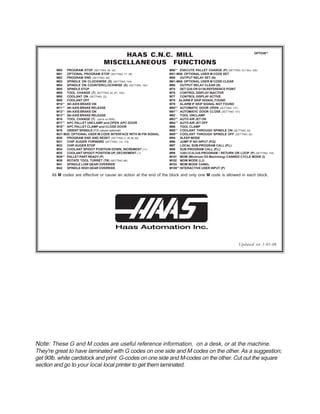

- 1. HAAS C.N.C. MILL PREPARATORY FUNCTIONS G00* RAPID POSITIONING MOTION (X,Y,Z,A,B) (SETTING 10, 56, 101) G01 LINEAR INTERPOLATION MOTION (X,Y,Z,A,B,F) G02 CIRCULAR INTERPOLATION MOTION CW (X,Y,Z,A,I,J,K,R,F) G03 CIRCULAR INTERPOLATION MOTION CCW (X,Y,Z,A,I,J,K,R,F) G04 DWELL (P) (P=seconds"."milliseconds) G09 EXACT STOP, NON-MODAL G10 PROGRAMMABLE OFFSET SETTING (X,Y,Z,A,L,P,R) G12 CW CIRCULAR POCKET MILLING (Z,I,K,Q,D,L,F) G13 CCW CIRCULAR POCKET MILLING (Z,I,K,Q,D,L,F) G17* CIRCULAR MOTION XY PLANE SELECTION (G02 or G03) (SETTING 56) G18 CIRCULAR MOTION ZX PLANE SELECTION (G02 or G03) G19 CIRCULAR MOTION YZ PLANE SELECTION (G02 or G03) G20* VERIFY INCH COORDINATE POSITIONING (SETTING 9, set to INCH) G21 VERIFY METRIC COORDINATE POSITIONING (SETTING 9 set to METRIC) G28 MACHINE ZERO RETURN THRU REF. POINT (X,Y,Z,A,B) (SETTING 108) G29 MOVE TO LOCATION THROUGH G28 REF. POINT (X,Y,Z,A,B) G31** FEED UNTIL SKIP FUNCTION (X,Y,Z,A,B,F) G35** AUTOMATIC TOOL DIAMETER MEASUREMENT (D,H,Z,F) G36** AUTOMATIC WORK OFFSET MEASUREMENT(X,Y,Z,A,B,I,J,K,F) G37** AUTOMATIC TOOL LENGTH MEASUREMENT (D,H,Z,F) G40* CUTTER COMP CANCEL G41/G42/G141 (X,Y) G41 2D CUTTER COMPENSATION, LEFT (X,Y,D) (SETTING 40, 43, 44, 58) G42 2D CUTTER COMPENSATION, RIGHT (X,Y,D) (SETTING 40, 43, 44, 58) G43 TOOL LENGTH COMPENSATION+ (H,Z) (SETTING 15) G44 TOOL LENGTH COMPENSATION- (H,Z) (SETTING 15) G47 TEXT ENGRAVING (X,Y,Z,R,I,J,P,E,F,) (Macro Variable 599 Change Serial #) G49* TOOL LENGTH COMPENSATION CANCEL G43/G44/G143 (SETTING 56) G50* SCALING G51 CANCEL (SETTING 56) G51** SCALING (X,Y,Z,P) (SETTING 71) G52 WORK OFFSET POSITIONING COORDINATE (SETTING 33, YASNAC) G52 GLOBAL WORK COORDINATE OFFSET SHIFT (SETTING 33, FANUC) G52 GLOBAL WORK COORDINATE OFFSET SHIFT (SETTING 33, HAAS) G53 MACHINE ZERO XYZ POSITIONING, NON-MODAL (X,Y,Z,A,B) G54* WORK OFFSET POSITIONING COORDINATE #1 (SETTING 56) G55 WORK OFFSET POSITIONING COORDINATE #2 G56 WORK OFFSET POSITIONING COORDINATE #3 G57 WORK OFFSET POSITIONING COORDINATE #4 G58 WORK OFFSET POSITIONING COORDINATE #5 G59 WORK OFFSET POSITIONING COORDINATE #6 G60 UNI-DIRECTIONAL POSITIONING (X,Y,Z,A,B) (SETTING 35) G61 EXACT STOP, MODAL (X,Y,Z,A,B) G64* EXACT STOP G61 CANCEL (SETTING 56) G65** MACRO SUB-ROUTINE CALL G68** ROTATION (G17,G18,G19,X,Y,Z,R) (OPTION) (SETTING 72, 73) G69* ROTATION G68 CANCEL (SETTING 56) G70 BOLT HOLE CIRCLE with a CANNED CYCLE (I,J,L) G71 BOLT HOLEARC with a CANNED CYCLE (I,J,K,L) G72 BOLT HOLESALONGANANGLE with a CANNED CYCLE (I,J,L) MODAL NON-MODAL DEFAULT * OPTIONAL ** G73 HIGH SPEED PECK DRILL CANNED CYCLE (X,Y,A,B,Z,I,J,K,Q,P,R,L,F) (SETTING 22, 52) G74 REVERSE TAPPING CANNED CYCLE (X,Y,A,B,Z,J,R,L,F) (SETTING 130, 133) G76 FINE BORING CANNED CYCLE (X,Y,A,B,Z,I,J,P,Q,R,L,F) (SETTING 27) G77 BACK BORE CANNED CYCLE (X,Y,A,B,Z,I,J,Q,R,L,F) (SETTING 27) G80* CANCEL CANNED CYCLE (SETTING 56) G81 DRILL CANNED CYCLE (X,Y,A,B,Z,R,L,F) G82 SPOT DRILL / COUNTERBORE CANNED CYCLE (X,Y,A,B,Z,P,R,L,F) G83 PECK DRILL DEEP HOLE CANNED CYCLE (X,Y,A,B,Z,I,J,K,Q,P,R,L,F) (SETTING 22, 52) G84 TAPPING CANNED CYCLE (X,Y,A,B,Z,J,R,L,F) (SETTING 130, 133) G85 BORE IN~BORE OUT CANNED CYCLE (X,Y,A,B,Z,R,L,F) G86 BORE IN~STOP~RAPID OUT CANNED CYCLE (X,Y,A,B,Z,R,L,F) G87 BORE IN~MANUAL RETRACT CANNED CYCLE (X,Y,A,B,Z,R,L,F) G88 BORE IN~DWELL~MANUAL RETRACT CANNED CYCLE (X,Y,A,B,Z,P,R,L,F) G89 BORE IN~DWELL~BORE OUT (X,Y,A,B,Z,P,R,L,F) G90* ABSOLUTE POSITIONING COMMAND G91 INCREMENTAL POSITIONING COMMAND (SETTING 29) G92 GLOBAL WORK COORDINATE SYSTEM SHIFT (FANUC) (HAAS) (SETTING 33) G92 SET WORK COORDINATE VALUE (YASNAC) (SETTING 33) G93 INVERSE TIME FEED MODE ON G94* INVERSE TIME FEED MODE OFF / FEED PER MINUTE ON (SETTING 56) G95 FEED PER REVOLUTION (SETTING 9, 56) G98* CANNED CYCLE INITIAL POINT RETURN (SETTING 56) G99 CANNED CYCLE "R" PLANE RETURN G100 MIRROR IMAGE G101 CANCEL G101 MIRROR IMAGE (X,Y,Z,A,B) (SETTING 45, 46, 47, 48, 80) G102 PROGRAMMABLE OUTPUT TO RS-232 (X,Y,Z,A,B) G103 LIMIT BLOCK LOOKAHEAD (P0-P15 for number control looks ahead) G107 CYLINDRICAL MAPPING (X,Y,Z,A,Q,R,) G110-G129 WORK OFFSET POSITIONING COORDINATE #7-26 G136** AUTOMATIC WORK OFFSET CENTER MEASUREMENT G141 3D+ CUTTER COMPENSATION (X,Y,Z,I,J,K,D,F) G143** 5-AXIS TOOL LENGTH COMPENSATION+ (X,Y,Z,A,B,H) (SETTING 15, 117) G150 GENERAL PURPOSE POCKET MILLING (X,Y,P,Z,I,J,K,Q,D,R,L,S,F) G153** 5-AXISHIGHSPEEDPECKDRILLCANNEDCYCLE(X,Y,A,B,Z,I,J,K,Q,P,E,L,F)(SETTING22) G154** SELECT WORK OFFSET POSITIONING COORDINATE P1-99 (P) G155** 5-AXIS REVERSE TAPPING CANNED CYCLE (X,Y,A,B,Z,J,E,L,F) G161** 5-AXIS DRILL CANNED CYCLE (X,Y,A,B,Z,E,L,F) G162** 5-AXIS SPOT DRILL / COUNTERBORE CANNED CYCLE (X,Y,A,B,Z,P,E,L,F) G163** 5-AXIS PECK DRILL CANNED CYCLE(X,Y,A,B,Z,I,J,K,Q,P,E,L,F) (SETTING 22) G164** 5-AXIS TAPPING CANNED CYCLE (X,Y,A,B,Z,J,E,L,F) G165** 5-AXIS BORE IN, BORE OUT CANNED CYCLE (X,Y,A,B,Z,E,L,F) G166** 5-AXIS BORE IN, STOP, RAPID OUT CANNED CYCLE (X,Y,A,B,Z,E,L,F) G169** 5-AXIS BORE IN, DWELL, BORE OUT (X,Y,A,B,Z,P,E,L,F) G174 NON-VERTICAL RIGID TAPPING CCW (X,Y,Z,F) G184 NON-VERTICAL RIGID TAPPING CW (X,Y,Z,F) G187 ACCURACY CONTROL FOR HIGH SPEED MACHINING (E) (SETTING 85) G188 G188 GET PROGRAM FROM PST (Program Schedule Table) Note: These G and M codes are useful reference information, on a desk, or at the machine. They're great to have laminated with G codes on one side and M codes on the other. As a suggestion; get 90lb. white cardstock and print G-codes on one side and M-codes on the other. Cut out the square section and go to your local local printer to get them laminated.

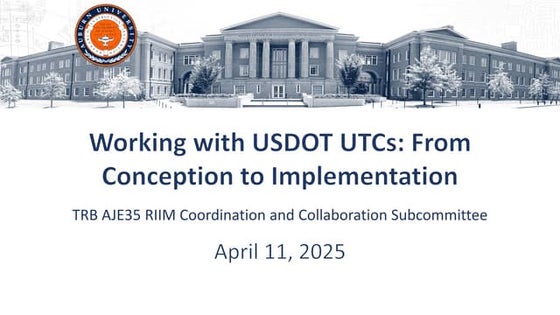

- 2. HAAS C.N.C. MILL MISCELLANEOUS FUNCTIONS M00 PROGRAM STOP (SETTING 39, 42) M01 OPTIONAL PROGRAM STOP (SETTING 17, 39) M02 PROGRAM END (SETTING 39) M03 SPINDLE ON CLOCKWISE (S) (SETTING 144) M04 SPINDLE ON COUNTERCLOCKWISE (S) (SETTING 144) M05 SPINDLE STOP M06 TOOL CHANGE (T) (SETTING 42, 87, 155) M08 COOLANT ON (SETTING 32) M09 COOLANT OFF M10** 4th AXIS BRAKE ON M11** 4th AXIS BRAKE RELEASE M12** 5th AXIS BRAKE ON M13** 5th AXIS BRAKE RELEASE M16 TOOL CHANGE (T) (same as M06) M17** APC PALLET UNCLAMP and OPEN APC DOOR M18** APC PALLET CLAMP and CLOSE DOOR M19 ORIENT SPINDLE (P,R values optional) M21-M28 OPTIONAL USER M CODE INTERFACE WITH M-FIN SIGNAL M30 PROGRAM END AND RESET (SETTING 2, 39, 56, 83) M31 CHIP AUGER FORWARD (SETTING 114, 115) M33 CHIP AUGER STOP M34 COOLANT SPIGOT POSITION DOWN, INCREMENT (+1) M35 COOLANT SPIGOT POSITION UP, DECREMENT (-1) M36** PALLET PART READY (P) M39 ROTATE TOOL TURRET (T#) (SETTING 86) M41 SPINDLE LOW GEAR OVERRIDE M42 SPINDLE HIGH GEAR OVERRIDE M50** EXECUTE PALLET CHANGE (P) (SETTING 121 thru 129) M51-M58 OPTIONAL USER M CODE SET M59 OUTPUT RELAY SET (N) M61-M68 OPTIONAL USER M CODE CLEAR M69 OUTPUT RELAY CLEAR (N) M75 SET G35 OR G136 REFERENCE POINT M76 CONTROL DISPLAY INACTIVE M77 CONTROL DISPLAY ACTIVE M78 ALARM IF SKIP SIGNAL FOUND M79 ALARM IF SKIP SIGNAL NOT FOUND M80** AUTOMATIC DOOR OPEN (SETTING 131) M81** AUTOMATIC DOOR CLOSE (SETTING 131) M82 TOOL UNCLAMP M83** AUTO AIR JET ON M84** AUTO AIR JET OFF M86 TOOL CLAMP M88** COOLANT THROUGH SPINDLE ON (SETTING 32) M89** COOLANT THROUGH SPINDLE OFF (SETTING 32) M95 SLEEP MODE M96 JUMP IF NO INPUT (P,Q) M97 LOCAL SUB-PROGRAM CALL (P,L) M98 SUB-PROGRAM CALL (P,L) M99 SUB/LOCALSUB-PROGRAM / RETURN OR LOOP (P) (SETTING 118) M101 MOM (Minimum Oil Machining) CANNED CYCLE MODE (I) M102 MOM MODE (I,J) M103 MOM MODE CANEL M109** INTERACTIVE USER INPUT (P) All M codes are effective or cause an action at the end of the block and only one M code is allowed in each block. Updated on 1-01-06 OPTION** Note: These G and M codes are useful reference information, on a desk, or at the machine. They're great to have laminated with G codes on one side and M codes on the other. As a suggestion; get 90lb. white cardstock and print G-codes on one side and M-codes on the other. Cut out the square section and go to your local local printer to get them laminated.