Rack & Screen

- 2. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. RACKS & SCREENS...

- 3. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. screen is a device with openings for removing bigger suspended or floating matter in sewage which would otherwise damage equipment or interfere with satisfactory operation of treatment units.

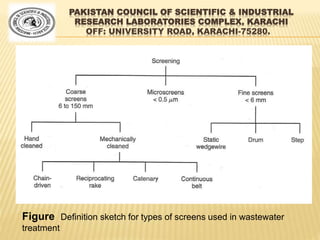

- 4. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. Figure Definition sketch for types of screens used in wastewater treatment

- 5. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. Design Consideration Velocity ’ā╝ The velocity of flow ahead of and through the screen varies and affects its operation. ’ā╝ The lower the velocity through the screen, the greater is the amount of screenings that would be removed from sewage. ’ā╝ However, the lower the velocity, the greater would be the amount of solids deposited in the channel.

- 6. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. ’ā╝ Hence, the design velocity should be such as to permit 100% removal of material of certain size without undue depositions. ’ā╝ Velocities of 0.6 to 1.2 mps through the open area for the peak flows have been used satisfactorily. ’ā╝ Further, the velocity at low flows in the approach channel should not be less than 0.3 mps to avoid deposition of solids.

- 7. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. Head loss ’ā╝ Head loss varies with the quantity and nature of screenings allowed to accumulate between cleanings. ’ā╝ Head loss through screens mainly depends on: ’ü▒ Size and amount of solids in waste water ’ü▒ Clear openings between bar ’ü▒ Method of cleaning and its frequency ’ü▒ Velocity of flow through the screens

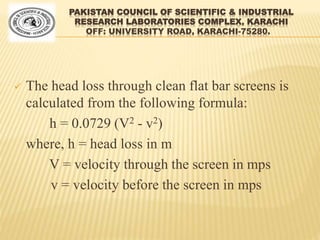

- 8. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. ’ā╝ The head loss through clean flat bar screens is calculated from the following formula: h = 0.0729 (V2 - v2) where, h = head loss in m V = velocity through the screen in mps v = velocity before the screen in mps

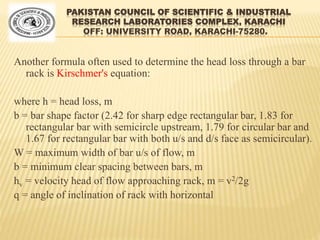

- 9. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. Another formula often used to determine the head loss through a bar rack is Kirschmer's equation: where h = head loss, m b = bar shape factor (2.42 for sharp edge rectangular bar, 1.83 for rectangular bar with semicircle upstream, 1.79 for circular bar and 1.67 for rectangular bar with both u/s and d/s face as semicircular). W = maximum width of bar u/s of flow, m b = minimum clear spacing between bars, m hv = velocity head of flow approaching rack, m = v2/2g q = angle of inclination of rack with horizontal

- 10. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280. The head loss through fine screen is given by where, h = head loss, m Q = discharge, m3/s C = coefficient of discharge (typical value 0.6) A = effective submerged open area, m2

- 11. PAKISTAN COUNCIL OF SCIENTIFIC & INDUSTRIAL RESEARCH LABORATORIES COMPLEX, KARACHI OFF: UNIVERSITY ROAD, KARACHI-75280.