Bai tap plc

- 1. CÃĄc và dáŧĨ áŧĐng dáŧĨng báŧ CPM2A Training Kit 1. ChÆ°ÆĄng trÃŽnh Äiáŧu khiáŧn trÃē chÆĄi dᚥng "ÄÆ°áŧng lÊn Äáŧnh Olympia" <MÃī tášĢ yÊu cᚧu > Sau khi ngÆ°áŧi dášŦn chÆ°ÆĄng trÃŽnh (Host) ÄÃĢ nÊu xong cÃĄc cÃĒu háŧi, cÃĄc ÄášĨu tháŧ§ (player) sáš― bášĨm nÚt phÃa trÆ°áŧc máš·t Äáŧ trášĢ láŧi cÃĒu háŧi. Ai bášĨm trÆ°áŧc trášĢ láŧi trÆ°áŧc. ChuÃīng (Buzzer) sáš― kÊu trong 10 giÃĒy sau khi bášĨt káŧģ ÄášĨu tháŧ§ nà o bášĨm nÚt. CÃđng lÚc ÄÃģ ÄÃĻn trÆ°áŧc máš·t ÄášĨu tháŧ§ ÄÃģ sáš― sÃĄng và sáš― cháŧ ÄÆ°áŧĢc tášŊt (Reset) báŧi ngÆ°áŧi dášŦnchÆ°ÆĄng trÃŽnh. CÃĄc Äᚧu và o ra Äᚧu và o Äᚧu ra 00000 - NÚt bášĨm ÄášĨu tháŧ§ 1 (PB1) 01000 - CÃēi 00001 - NÚt bášĨm ÄášĨu tháŧ§ 2 (PB2) 01001 - ÄÃĻn cáŧ§a ÄášĨu tháŧ§ 1 00002 - NÚt bášĨm ÄášĨu tháŧ§ 3 (PB3) 01002 - ÄÃĻn cáŧ§a ÄášĨu tháŧ§ 2 00003 - NÚt tášŊt (Reset) 01003 - ÄÃĻn cáŧ§a ÄášĨu tháŧ§ 3 Ladder Diagram : Main 1 Network 1 Main 1 - Who press first (Priority Determination) This program is to determine which player press the switch first, after the host have finished asking a question. Network 1 - Interlocked Interlocked network for 3 player playing the game - 1 - 000.00 005.00 Reset TIM000 010.02 PB1 000.01 PLAYER2 010.01 005.01010.03 PLAYER3 010.03 PB2 000.02 PLAYER1 010.02 PLAYER3 010.01 PB2 005.00 PLAYER2 PLAYER1 Buzzer Player 1 Player 2 Player 3

- 2. Network 2 - Buzzer ON Buzzer when any switch is pressed and timer will cut the buzzer after specified time Network 3 - Player 1 Player 1 Network Network 4 - Player 2 Player 2 Network Network 5 - Player 3 Player 3 Network Network 6 - Reset Reset for the Game Network 7 2. Äiáŧu khiáŧn ÄÃģng máŧ cáŧa gara ÃītÃī - 2 - END(01) 010.00 TIM 000 #0100 BUZZER 005.00 000.00 010.01 RST 010.02 PB1 010.01 PLAYER2 000.03010.03 PLAYER3 PLAYER1 PLAYER1 000.01 010.02 RST 010.01 PB2 010.02 PLAYER1 000.03010.03 PLAYER3 PLAYER2 PLAYER2 000.02 010.03 PLAYER3RST 010.01 PB3 010.03 PLAYER1 000.03010.02 PLAYER2 PLAYER3 005.01 RESET 000.03 RST

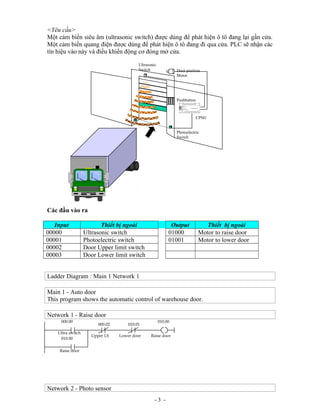

- 3. <YÊu cᚧu> Máŧt cášĢm biášŋn siÊu ÃĒm (ultrasonic switch) ÄÆ°áŧĢc dÃđng Äáŧ phÃĄt hiáŧn Ãī tÃī Äang lᚥi gᚧn cáŧa. Máŧt cášĢm biášŋn quang Äiáŧn ÄÆ°áŧĢc dÃđng Äáŧ phÃĄt hiáŧn Ãī tÃī Äang Äi qua cáŧa. PLC sáš― nhášn cÃĄc tÃn hiáŧu và o nà y và Äiáŧu khiáŧn Äáŧng cÆĄ ÄÃģng máŧ cáŧa. CÃĄc Äᚧu và o ra Input Thiášŋt báŧ ngoà i Output Thiášŋt báŧ ngoà i 00000 Ultrasonic switch 01000 Motor to raise door 00001 Photoelectric switch 01001 Motor to lower door 00002 Door Upper limit switch 00003 Door Lower limit switch Ladder Diagram : Main 1 Network 1 Main 1 - Auto door This program shows the automatic control of warehouse door. Network 1 - Raise door Network 2 - Photo sensor - 3 - 000.00 010.00 010.00 Ultra switch 010.01000.02 Upper LS Lower door Raise door Raise door Door position Motor Pushbutton Ultrasonic Switch CPM1 Photoelectric Switch

- 4. Sense unit differentiation down Network 3 - Lower door Network 4 - End Timing diagram 00000 Ultrasonic switch 00002 Upper limit switch 10000 Motor to raise door 00001 Photoelectric switch 04000 DIFD 00003 Lower limit switch 10001 Motor to low door - 4 - END(01) 200.00 010.01 010.01 010.00000.03 Upper LS Lower door Lower door Raise door 200.00 DIFD(14))((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((

- 5. 3. Táŧą Äáŧng bÃīi trÆĄn (Lubrication ) dᚧu cho bÃĄnh xe <MÃī tášĢ> Khi bÃĄnh xe di chuyáŧn váŧ phÃa cášĢm biášŋn S1, S1 sáš― phÃĄt hiáŧn bÃĄnh xe và sáš― ra tÃn hiáŧu cho van Äiáŧn táŧŦ ( Valve V1) Äáŧ cášĨp dᚧu bÃīi trÆĄn cho bÃĄnh xe. Van V1 sáš― máŧ trong máŧt khoášĢng tháŧi gian ngášŊn Äáŧ cášĨp máŧt lÆ°áŧĢng dᚧu Äáŧnh trÆ°áŧc cho bÃĄnh xe. Khi cášĢm biášŋn S2 phÃĄt hiáŧn máŧĐc dᚧu trong báŧn cháŧĐa (Tank) thášĨp, nÃģ sáš― ra tÃn hiáŧu cášĢnh bÃĄo. CÃĄc Äᚧu và o ra Input Thiášŋt báŧ ngoà i Output Thiášŋt báŧ ngoà i 00000 Position detection (S1) 01000 Electromagnetic valve for oil supply 00001 Lower limit of level (S2) 01001 Oil shortage alarm indicator Ladder Diagram : Main 1 Network 1 Main 1 - Auto lubricate Auto lubrication of gear Network 1 - Start Network 2 - Open valve Open valve and delay 1.5 sec. - 5 - Position detection DIFD(13) 200.00 Oil shortage alarm indicatorSYSMAC CPM1 S2 Lubricating Oil Tank

- 6. Network 3 - Oil shortage Network 4 - End Timing diagram 00000 Position Detection 04000 DIFU 10000 TIM 000 Valve Opens Timer's preset time 00001 Lower limit of oil level 10001 Oil shortage alarm indicator 4. Äiáŧu khiáŧn Äáŧng cÆĄ bÄng tášĢi BÄng tášĢi gáŧm cÃģ 3 phÃĒn Äoᚥn, và cᚧn Äiáŧu khiáŧn sao cho Äáŧng cÆĄ cáŧ§a máŧi phÃĒn Äoᚥn cháŧ chᚥy khi cÃģ Äáŧi tÆ°áŧĢng (tášĨm Äáŧng- copper plate) Äang nášąm trÊn phÃĒn Äo ᚥn tÆ°ÆĄng áŧĐng. Váŧ trà cáŧ§a tášĨm kim loᚥi ÄÆ°áŧĢc xÃĄc Äáŧnh báŧi cÃĄc cášĢm biášŋn tiáŧm cášn Ä áš·t gᚧn nÃģ (Sensor 1,2,3). Khi tášĨm kim loᚥi nášąm trong khoášĢng cÃĄch phÃĄt hiáŧn cáŧ§a 1 sensor, Äáŧng cÆĄ tÆ°ÆĄng áŧĐng sáš― vášŦn là m viáŧc. Khi tášĨm kim loᚥi nášąm ngoà i khoášĢng cÃĄch phÃĄt hiáŧn cáŧ§a sensor, máŧt timer tráŧ sáš― ÄÆ°áŧĢc kÃch hoᚥt và khi tháŧi gian Äáš·t cáŧ§a timer hášŋt, Äáŧng cÆĄ tÆ°ÆĄng áŧĐng sáš― ngáŧŦng. I/O Input Thiášŋt báŧ ngoà i Output Thiášŋt báŧ ngoà i 00000 Sensor 1 01000 Motor 1 - 6 - 010.01000.01 Lower level Oil shortage END(01) 200.00 010.01 010.01 TIM 000 Valve close #0015 TIM000 Valve close Valve opens Valve opens 1 scan time 1.5 sec

- 7. 00001 Sensor 2 01001 Motor 2 00002 Sensor 3 01002 Motor 3 Ladder Diagram : Main 1 Network 1 Main 1 - Conveyor control Conveyor belt control application Network 1 - Motor 2 Network 2 - Motor 1 Network 3 - Delay for 2 sec Network 4 - Sensor 1 - 7 - 000.02 010.01 S3 010.01TIM 000 Motor 2 Motor 2 S2 010.00 Motor 1 000.01 TIM 000 #0020 000.01 010.00 S2 010.00TIM 001 Motor 1 Motor 1 000.00 200.00 S1 200.00 TIM 001 Copper plate Sensor 1 Sensor 2 Sensor 3 CPM1 Motor 1 Motor 2 Motor 3

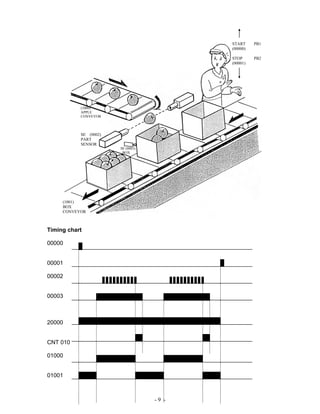

- 8. Network 5 - Delay for 2 sec Network 6 - Motor 3 Network 7 - End 5. Äiáŧu khiáŧn dÃĒy chuyáŧn ÄÃģng gÃģi (Packing Line Control) YÊu cᚧu : Khi nÚt bášĨm PB 1 (Start) ÄÆ°áŧĢc bášĨm, bÄng tášĢi háŧp bášŊt Äᚧu chuyáŧn Äáŧng. Khi phÃĄt hiáŧn sáŧą cÃģ máš·t cáŧ§a háŧp, bÄng tášĢi háŧp (Box Conveyor ) dáŧŦng và bÄng tášĢi tÃĄo (Apple conveyor) bášŊt Äᚧu chuyáŧn Äáŧng. CášĢm biášŋn Äášŋm (SE1) sáš― Äášŋm sáŧ lÆ°áŧĢng quášĢ tÃĄo cho Äášŋn khi Äᚥt 10 quášĢ. BÄng tášĢi tÃĄo lÚc nà y sáš― dáŧŦng và bÄng tášĢi háŧp lᚥi kháŧi Äáŧng lᚥi. Báŧ Äášŋm sáš― ÄÆ°áŧĢc reset và hoᚥt Äáŧng lᚥi láš·p lᚥi cho Äášŋn khi nÚt PB2 (Stop) ÄÆ°áŧĢc bášĨm. CÃĄc Äᚧu và o ra Input Thiášŋt báŧ ngoà i Output Thiášŋt báŧ ngoà i 00000 START Push button (PB1) 01000 Apple Conveyor 00001 STOP Push button (PB2) 01001 Box Conveyor 00002 Part Present (SE1) 00003 Box Present (SE2) - 8 - END(01) S1 200.00 000.00 TIM 001 #0020 010.02 Motor 3NC 253.13

- 9. Timing chart 00000 00001 00002 00003 20000 CNT 010 01000 01001 - 9 - START (00000) STOP (00001) PB1 PB2 (1000) APPLE CONVEYOR SE (0002) PART SENSOR (1001) BOX CONVEYOR SE (0003) BOX

- 10. Ladder Diagram : Main 1 Network 1 Main 1 - Packing Packing line control for Apples Network 1 - Start condition Network 2 - Apples conveyor Network 3 - Counter Counter preset at 10 Network 4 - Box conveyor Network 5 - END - 10 - 200.00 RUN 010.00010.01 BoxCon CONVYR END(01) SE2 000.02 SE1 000.03 CNT 010 #0010 CNT 010 000.03 S1 010.01200.00 BoxConRUN SE2 PB2 000.00 200.00 PB1 200.00000.01 RUN RUN

- 11. Mnemonic Codes 6. Äiáŧu khiáŧn bÃĢi Äáŧ xe - 11 - ÄáŧaÃa cháŧhà Láŧnhnh ThTh. sáŧsÃĻ ÄáŧaÃa cháŧhà Láŧnhnh ThTh. sáŧsÃĻ 0000 LDLD 00000 0008 LDLD NO TO T 00003 0001 OROR 20000 0009 CNTNT 010 0002 ANDND NOTOT 00001 # 0010 0003 OUTUT 20000 0010 LDLD CNTNT 010 0004 LDLD 20000 0011 OROR NOTOT 00003 0005 ANDND NOTOT 01001 0012 ANDND 20000 0006 OUTUT 01000 0013 OUTUT 01001 0007 LDLD 00002 0014 ENDND (01)

- 12. ÄÃĒy là máŧt chÆ°ÆĄng trÃŽnh Äiáŧu khiáŧn bÃĢi Äáŧ xe ÄÆĄn giášĢn cháŧ cho phÃĐp táŧi Äa là 100 xe ÄÆ°áŧĢc Äáŧ tᚥi máŧt tháŧi Äiáŧm. Máŧi khi cÃģ máŧt xe máŧi Äi và o, Sensor (S1) sáš― phÃĄt hiáŧn và PLC sáš― cáŧng 1 và o táŧng sáŧ xe hiáŧn Äang trong bÃĢi Äáŧ và sáš― tráŧŦ Äi 1 khi Sensor (S2) phÃĄt hiáŧn cÃģ xe Äi ra kháŧi bÃĢi Äáŧ. Khi 100 xe ÄÃĢ Äáŧ trong bÃĢi, ÄÃĻn hiáŧu "CAR PARK FULL" sáš― sÃĄng Äáŧ bÃĄo cÃĄc xe khÃĄc khÃīng ÄÆ°áŧĢc và o bÃĢi. Car coming in I/O INPUT OUTPUT 00000 Sensor S1 01000 Car park full sign 00001 Sensor S2 Ladder Diagram : Main 1 Network 1 Main 1 - Car Park Control Application: Car Park Control Network 1 - Car in Network 2 - Add 1 - 12 - 200.00 Car in CLC(41) ADD(13) HR00 #0001 HR00 CARPARKFULL!! (100) 000.00 DIFU(13) 200.00 Car in S1

- 13. Network 3 - Car out Network 4 - Subtract 1 Network 5 - Compare Network 6 - End - 13 - 255.06 255.05 =Flag 010.00 Car Park full >Flag 253.13 NC CPM(20) HR00 #0100 End(01) 200.01 S2 CLC(41) SUB(31) HR00 #0001 HR00 000.01 DIFU(13) 200.01 Car out S2