Intervention Engineering IWS Methodology

- 1. INSPECTION ROV SPECIALISTS HULL General Visual Inspection (GVI) of the hull shell plating can be conducted using either of these two methods: ŌĆó Free flying ŌĆō gives a general overview of plating condition and allows for marine growth assessment. Using this method, a better field of view is achieved however movement in the video is evident. ŌĆó Attached to the hull (via crawler attachment) ŌĆō this approach ensures better video quality due to perfectly still and stable platform; however, field of view is limited due to proximity to hull (leading to an increased number of passes). Lossless 1080p HD video and effective lighting that tracks the camera provides the required detail for visual inspection, marine growth and coating assessment. Hull plating inspection routes are to be outlined in the Inspection Plan submitted to the Class Society for approval.

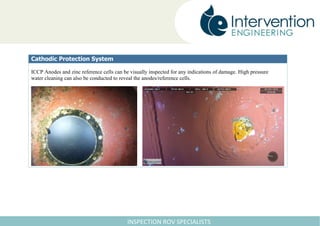

- 2. INSPECTION ROV SPECIALISTS Cathodic Protection System ICCP Anodes and zinc reference cells can be visually inspected for any indications of damage. High pressure water cleaning can also be conducted to reveal the anodes/reference cells.

- 3. INSPECTION ROV SPECIALISTS Sea Chests Intervention Engineering can collect high quality footage through the gratings for coating condition, marine growth and anode assessment using the 1080p HD cameras. High pressure water cleaning may be required to remove marine growth from sea chest gratings to allow for higher water flow and enable internal inspection through the gratings.

- 4. INSPECTION ROV SPECIALISTS Overboard Discharges Overboard discharges can be inspected using SD or HD cameras. Using the HD camera externally on a free flying ROV enables a rapid overview of the overboard outlet and its surroundings. Some components of the internal valve are normally visible. By using the crawler skid, the added stability enables high quality CVI of the penetration including welds. Intervention Engineering can also utilise a self-illuminated PTZ camera on a pole that is sent into the overboard, allowing detailed CVI of larger diameter oveboards (>200mm). For smaller overboards a Micro Endoscopic Camera (10.9mm OD) with inbuilt lights on 10m lead allows for internal inspection. This camera can also travel through the distance piece and inspect the valve condition. If overboard labels are covered by marine growth, high pressure water or brushes can be used to clean the identification mark.

- 5. INSPECTION ROV SPECIALISTS Propeller The propeller is normally inspected with the ROV in a free-flying mode. All propeller blade leading and trailing edges, rope guard, propeller boss and nut cap are inspected closely and condition is noted. Cleaning can be completed using high pressure water. The crawler can be utilised to provide a stable platform for cleaning and close visual inspection. Photogrammetry can be used to model and size potential defects.

- 6. INSPECTION ROV SPECIALISTS Rudder The rudder and rudder horn can be inspected and spot cleaning can be conducted on identified areas of interest. Water cleaning is normally required to clean in crevices around rudder horn. Intervention Engineering have previously completed a fully diverless in-water survey on a vessel with an in-service rudder. The governing Class Society (ABS) were satisfied with the data collected and did not require additional diver inspection on the rudder.