HACCP PLAN FOR FRUIT JUICE INDUSTRY[000157]

- 1. HACCP PLAN FOR FRUIT JUICE INDUTRY Presented by, Ajna Alavudeen

- 2. HACCP ’éó HACCP is a management system in which food safety is addressed through the analysis and control of biological , chemical , physical hazards from raw materials production and handling to manufacture , distribution and consumption of the finished products.

- 3. SEVEN PRINCIPLES??? ’ā╝ ’ā╝ ’ā╝ ’ā╝ ’ā╝ ’ā╝ ’ā╝ List all food hazards that are reasonably likely to occur. List the caps. List the critical limit that that shall be met at each caps. List the monitoring procedures. Include any corrective action plans. List the validation and verification procedures. Provide for a record keeping system.

- 4. JIVE Kerala horticultural development program fruit processing factory. ’éó Products: R.T.S, Candy, Concentrated mango pulp line . ’éó

- 5. READY TO SERVE This is a type of fruit juice which contain at least 10% fruit juice. ’éó 10% TSS. ’éó About 0.3% acid. ’éó Not diluted before serving. ’éó

- 6. PROCESSING Fruit Mixing with strained syrup solution (sugar +water +acid) Heated Homogenization Sterilization Filling tetra packing Cooling storage

- 7. HAZARDS IN PROCESSING Processing stage ’é¦ ’é¦ Receiving of fruit Storage ’é¦Cleaning Physical contamination Chemical contamination Biological contamination Sand , pest, stones, wood Naturally occurring substances Pesticides, fungicides Toxic chemicals,mycotoxin. Presence of microorganism Sand ,stones, wood Chemical contamination Presence of microorganism Poorly maintained equipments Chemical Contaminations in water Microbial quality of water Cross contamination Quality of water, Cross contamination.

- 8. Belt washing d Chemical contamination in water, Excess sanitation Microbial cross contamination, microbial quality of water Peeling Presence of metal pieces Chemical contaminations from chemical or pesticides Contamination due to unclean equipment Pulping Presence of metal pieces, foreign body or dust contamination from production environment. none Contamination due to un clean equipment. Mixing Screw, metal pieces none Cross contamination

- 9. Holdingh Contaminations from warehouses practices None Cross contamination Strainer None None Cross contamination Sanitizer residue Microbial survival due to insufficient temperature or holding time. Thermal processing Unsanitized equipment.

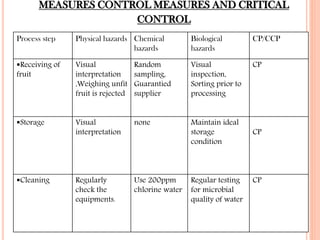

- 11. MEASURES CONTROL MEASURES AND CRITICAL CONTROL Process step Physical hazards Chemical hazards Biological hazards CP/CCP ’é¦Receiving of fruit Visual interpretation ,Weighing unfit fruit is rejected Random sampling, Guarantied supplier Visual inspection, Sorting prior to processing CP ’é¦Storage Visual interpretation none Maintain ideal storage condition ’é¦Cleaning Regularly check the equipments. Use 200ppm chlorine water Regular testing for microbial quality of water CP CP

- 12. Regular testing for chemical quality of water Regular testing CP for microbiologica l quality of water ’é¦belt conveyor washing None ’é¦Peeling Precaution for maintenance ,screens, magnet downstream will remove debris None Precaution for cleaning ,sanitizing equipment CP ’é¦Pulping Precaution for maintenance ,screens, magnet Downstream will remove debris none Precaution for cleaning, sanitizing equipment CP ’é¦Mixing Use of metal detectors CP

- 13. ’é¦Holding tank Personnel hygiene policies were adopted Regular testing G for chemical quality of water CP ’é¦Strainer Precaution for cleaning and sanitizing equipments ’é¦Thermal processing Temperature &pressure should be maintained ’é¦Cooling section Temperature CP should be maintained& is equipped with temperature sensors. ’é¦Tetra packaging Visual inspection Correct Cleaning procedures have to be CCP CP

- 14. CRITICAL LIMITS ’éó Sterilization: temperature;121┬║c for 15 psi.

- 15. MONITORING Receiving of fruits Check : visual inspection Record: Presence/absence of contaminants in goods ’é¦ Storage of fruits Check : regular inspection Record :any security maintenance ’é¦ Peeling Check : regular inspection Record: record any security maintenance ’é¦ Pulping Check: regular inspection Record: record any security maintenance ’é¦

- 16. Mixing Check the equipments regularly Record any security maintenance ’é¦ Holding Check: ’é¦ Strainer Check : regular inspection of equipments Record : Record any resulting maintenance ’é¦ Thermal processing Check: Using thermometers and temperature sensors Record : Temperature and time ’é¦ Tetra pack Check : visual check Record :filling check ’é¦

- 17. CORRECTIVE ACTIONS ’āś Purchase/delivery ŌĆōreject contaminated or unripe fruit ’āś Storage- repair/replace storage structure ’āś Cleaning ŌĆō contaminated water is eliminated ’āś Belt washing- contaminated water is eliminated ’āś Peeling ŌĆō repair defective articles

- 18. ’āś Holding tube ŌĆō precaution during sampling ’āś Strainer ŌĆō replace defective article ’āś Thermal processing- boil up to the stated period ’āś Cooling process- cool up to the stated period ’āś Filling ŌĆōdiscard defect product during filling

- 19. DOCUMENTATION Audit records ’üČ Equipment records ’üČ Product records ’üČ Staff records ’üČ Cleaning schedule records ’üČ Customer confidence records ’üČ Hazard analysis plan ’üČ Record the inspection visit or investigation ’üČ

- 20. THANK YOU