01.02 aac masonry units

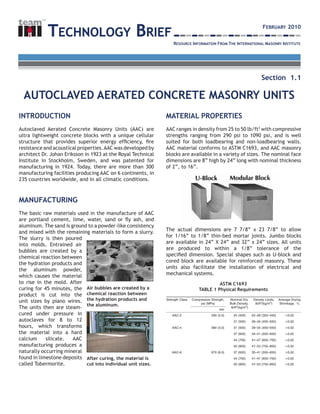

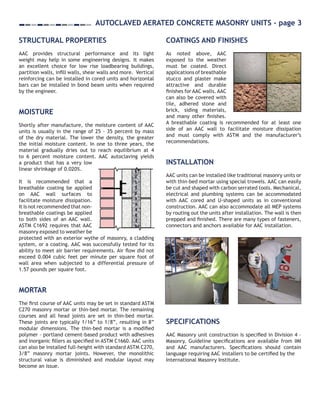

- 1. INTRODUCTION Autoclaved Aerated Concrete Masonry Units (AAC) are ultra lightweight concrete blocks with a unique cellular structure that provides superior energy efficiency, fire resistance and acoustical properties.AAC was developed by architect Dr. Johan Eriksson in 1923 at the Royal Technical Institute in Stockholm, Sweden, and was patented for manufacturing in 1924. Today, there are more than 300 manufacturing facilities producing AAC on 6 continents, in 235 countries worldwide, and in all climatic conditions. MANUFACTURING The basic raw materials used in the manufacture of AAC are portland cement, lime, water, sand or fly ash, and aluminum. The sand is ground to a powder-like consistency and mixed with the remaining materials to form a slurry. The slurry is then poured into molds. Entrained air bubbles are created by a chemical reaction between the hydration products and the aluminum powder, which causes the material to rise in the mold. After curing for 45 minutes, the product is cut into the unit sizes by piano wires. The units then are steam- cured under pressure in autoclaves for 8 to 12 hours, which transforms the material into a hard calcium silicate. AAC manufacturing produces a naturally occurring mineral found in limestone deposits called Tobermorite. MATERIAL PROPERTIES AAC ranges in density from 25 to 50 lb/ft3 with compressive strengths ranging from 290 psi to 1090 psi, and is well suited for both loadbearing and non-loadbearing walls. AAC material conforms to ASTM C1693, and AAC masonry blocks are available in a variety of sizes. The nominal face dimensions are 8ŌĆØ high by 24ŌĆØ long with nominal thickness of 2ŌĆØ, to 16ŌĆØ. The actual dimensions are 7 7/8ŌĆØ x 23 7/8ŌĆØ to allow for 1/16ŌĆØ to 1/8ŌĆØ thin-bed mortar joints. Jumbo blocks are available in 24ŌĆØ X 24ŌĆØ and 32ŌĆØ x 24ŌĆØ sizes. All units are produced to within a 1/8ŌĆØ tolerance of the specified dimension. Special shapes such as U-block and cored block are available for reinforced masonry. These units also facilitate the installation of electrical and mechanical systems. TECHNOLOGY BRIEF RESOURCE INFORMATION FROM THE INTERNATIONAL MASONRY INSTITUTE TM Autoclaved Aerated Concrete Masonry Units Section 1.1 February 2010 Air bubbles are created by a chemical reaction between the hydration products and the aluminum. After curing, the material is cut into individual unit sizes. ASTM C1693 TABLE 1 Physical Requirements

- 2. AIR BARRIER UPDATE - page 2 IMI 2009. ALL RIGHTS RESERVED.C This document is intended for the use of industry professionals who are competent to evaluate the significance and limitations of the information provided herein. This publication should not be used as the sole guide for masonry design and construction, and IMI disclaims any and all legal responsibility for the consequences of applying the information. International Masonry Institute 42 East Street Annapolis, MD 21401 1-800-IMI-0988 www.imiweb.org Autoclaved Aerated Concrete Masonry Units - page 2 CODES AND STANDARDS AAC products and systems carry nationally recognized third- party approvals from ASTM, Underwriters Laboratories (UL), International Code Council (ICC) , Autoclaved Aerated Concrete Producers Association (AACPA Certifications) and the Masonry Standards Joint Committee (MSJC 530 Code). ASTM Standards contain material and installation specifications forAAC as illustrated in Figure 1 below. There are more than 40 UL listings for AAC. There are numerous other codes and standards, as well as manufacturerŌĆÖs recommendations and guidelines. FIRE RESISTANCE AAC has one of the highest hourly fire-resistance ratings per inch of any building material. A 4ŌĆØ AAC wall carries a 4-hour (UL) rating. AAC is non-combustible ŌĆō it will not burn. AAC units offer excellent fire protection for fire- rated walls, stairwells, columns, beams, corridors and shaft walls. AAC units have passed both the Fire Test and the Hose-Stream Test sections of ASTM E119. AAC is not only versatile structurally but its fire resistance properties are outstanding. THERMAL ENERGY EFFICIENCY Autoclaved Aerated Concrete Masonry Unit (AAC) walls are energy efficient. An 8ŌĆØ AAC block wall has a steady- state R-value of approximately 10, and a higher total equivalent performance R-value when factoring Dynamic Benefit for Massive Systems (DBMS or thermal mass). This means AAC can store and release thermal energy to control the temperature of indoor environments. This results in significantly reduced heating and cooling cost ACOUSTIC PROPERTIES AACŌĆÖs high surface mass, coupled with the mechanical vibration energy dampening within its porous structure, produces a construction material with remarkable sound insulation and absorption qualities. Since its porous internal structure is comprised of 60%-70% air, AAC absorbs much more sound than conventional concrete and other materials, effectively reducing sound wave transmission. This makes it ideal for construction projects that require a high level of acoustic insulation, such as schools, apartments, hotels, and entertainment facilities. One county school board has constructed over 150 classroom buildings, a media center, and a new middle school with AAC. According to the school board, ŌĆ£The acoustics are outstanding and visitors universally note the quality of the environment in the classrooms.ŌĆØ AAC has passed both the Fire Test and Hose-Stream Test sections of ASTM E119. Autoclaved Aerated Concrete Masonry Unit (AAC) walls are energy efficient. An 8ŌĆØ AAC block wall has a steady- state R-value of approximately 10, and a higher total equivalent performance R-value when factoring Dynamic Benefit for Massive Systems (DBMS or thermal mass). This means AAC can store and release thermal energy to control the temperature of indoor environments. This results in significantly reduced heating and cooling cost. ASTM C1660 Standard Specification for Thin-bed Mortar for Autoclaved Aerated Concrete (AAC) Masonry ASTM C1691 Standard Specification for Unreinforced Autoclaved Aerated Concrete (AAC) Masonry Units ASTM C1692 Standard Practice for Construction and Testing of Autoclaved Aerated Concrete (AAC) Masonry ASTM C1693 Standard Specification for Autoclaved Aerated Concrete (AAC) Masonry Figure 1 - ASTM Standards for Autoclaved Aerated Concrete Masonry

- 3. AIR BARRIER UPDATE - page 2 IMI 2009. ALL RIGHTS RESERVED.C This document is intended for the use of industry professionals who are competent to evaluate the significance and limitations of the information provided herein. This publication should not be used as the sole guide for masonry design and construction, and IMI disclaims any and all legal responsibility for the consequences of applying the information. International Masonry Institute 42 East Street Annapolis, MD 21401 1-800-IMI-0988 www.imiweb.org Autoclaved Aerated Concrete Masonry Units - page 3 STRUCTURAL PROPERTIES AAC provides structural performance and its light weight may help in some engineering designs. It makes an excellent choice for low rise loadbearing buildings, partition walls, infill walls, shear walls and more. Vertical reinforcing can be installed in cored units and horizontal bars can be installed in bond beam units when required by the engineer. MOISTURE Shortly after manufacture, the moisture content of AAC units is usually in the range of 25 - 35 percent by mass of the dry material. The lower the density, the greater the initial moisture content. In one to three years, the material gradually dries out to reach equilibrium at 4 to 6 percent moisture content. AAC autoclaving yields a product that has a very low linear shrinkage of 0.020%. It is recommended that a breathable coating be applied on AAC wall surfaces to facilitate moisture dissipation. It is not recommended that non- breathable coatings be applied to both sides of an AAC wall. ASTM C1692 requires that AAC masonry exposed to weather be protected with an exterior wythe of masonry, a cladding system, or a coating. AAC was successfully tested for its ability to meet air barrier requirements. Air flow did not exceed 0.004 cubic feet per minute per square foot of wall area when subjected to a differential pressure of 1.57 pounds per square foot. MORTAR The first course of AAC units may be set in standard ASTM C270 masonry mortar or thin-bed mortar. The remaining courses and all head joints are set in thin-bed mortar. These joints are typically 1/16ŌĆØ to 1/8ŌĆØ, resulting in 8ŌĆØ modular dimensions. The thin-bed mortar is a modified polymer ŌĆō portland cement-based product with adhesives and inorganic fillers as specified in ASTM C1660. AAC units can also be installed full-height with standard ASTM C270, 3/8ŌĆØ masonry mortar joints. However, the monolithic structural value is diminished and modular layout may become an issue. COATINGS AND FINISHES As noted above, AAC exposed to the weather must be coated. Direct applications of breathable stucco and plaster make attractive and durable finishes for AAC walls. AAC can also be covered with tile, adhered stone and brick, siding materials, and many other finishes. A breathable coating is recommended for at least one side of an AAC wall to facilitate moisture dissipation and must comply with ASTM and the manufacturerŌĆÖs recommendations. INSTALLATION AAC units can be installed like traditional masonry units or with thin-bed mortar using special trowels. AAC can easily be cut and shaped with carbon serrated tools. Mechanical, electrical and plumbing systems can be accommodated with AAC cored and U-shaped units as in conventional construction. AAC can also accommodate all MEP systems by routing out the units after installation. The wall is then prepped and finished. There are many types of fasteners, connectors and anchors available for AAC installation. SPECIFICATIONS AAC Masonry unit construction is specified in Division 4 ŌĆō Masonry. Guideline specifications are available from IMI and AAC manufacturers. Specifications should contain language requiring AAC installers to be certified by the International Masonry Institute.

- 4. AIR BARRIER UPDATE - page 2 IMI 2009. ALL RIGHTS RESERVED.C This document is intended for the use of industry professionals who are competent to evaluate the significance and limitations of the information provided herein. This publication should not be used as the sole guide for masonry design and construction, and IMI disclaims any and all legal responsibility for the consequences of applying the information. International Masonry Institute 42 East Street Annapolis, MD 21401 1-800-IMI-0988 www.imiweb.org AIR BARRIER UPDATE - page 2 IMI 2010. ALL RIGHTS RESERVED.C This document is intended for the use of industry professionals who are competent to evaluate the significance and limitations of the information provided herein. This publication should not be used as the sole guide for masonry design and construction, and IMI disclaims any and all legal responsibility for the consequences of applying the information. International Masonry Institute 42 East Street Annapolis, MD 21401 1-800-IMI-0988 www.imiweb.org DESIGNING WITH AAC AAC can be shaped to conform to any design and can accommodate almost any detail. AAC is excellent for all buildings, including schools, hotels, dormitories, commercial structures, industrial facilities and homes. AAC can be used for interior partitions, loadbearing walls, back-up walls, firewalls, stair enclosures, elevator shafts, column wraps, shafts and chutes. Autoclaved Aerated Concrete Masonry Units - page 4 AAC IS GREEN Autoclaved Aerated Concrete (AAC) is an environmentally friendly building material that is used to save energy and enhance the quality of the built environment. AACŌĆÖs high R-values contribute directly to the goals of higher performing building envelopes as well as to more specific building energy conservation goals such as those found in US Green Building CouncilŌĆÖs Leadership in Energy and Environmental Design (LEED) green building certification. Used in interior wall systems, AAC is capable of further enhancing thermal efficiency by absorbing excess heat from internal loads emitted by people, lights, and equipment. AAC contains no Volatile Organic Compounds (VOCŌĆÖs ), an area of specific concern in the design and construction of interior environments. AAC can further be coated by a variety of low VOC materials. These attributes directly address the intents of LEED Indoor Environmental Quality Low- Emitting Materials credits.For answers to specific questions regarding AAC, call 1-800-IMI-0988. ADVANTAGES OF AAC ŌĆó Lightweight ŌĆó Acoustically beneficial ŌĆó Offers design versatility ŌĆó Durable ŌĆó Energy efficient ŌĆó Structural ŌĆó Long lasting ŌĆó Environmentally friendly (Green) ŌĆó Weather resistant ŌĆó Compatible ŌĆó Mold resistant ŌĆó Easy to use ŌĆó Fire resistant ŌĆó Termite & pest resistant ŌĆó Cost effective ŌĆó Non-combustible ŌĆó Reduced construction time