04 movement types and transfer requirement

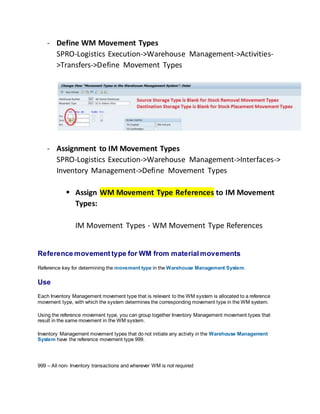

- 1. - Define WM Movement Types SPRO-Logistics Execution->Warehouse Management->Activities- >Transfers->Define Movement Types - Assignment to IM Movement Types SPRO-Logistics Execution->Warehouse Management->Interfaces-> Inventory Management->Define Movement Types  Assign WM Movement Type References to IM Movement Types: IM Movement Types - WM Movement Type References Reference movement type for WM from material movements Reference key for determining the movement type in the Warehouse Management System. Use Each Inventory Management movement type that is relevant to the WM system is allocated to a reference movement type, with which the system determines the corresponding movement type in the WM system. Using the reference movement type, you can group together Inventory Management movement types that result in the same movement in the WM system. Inventory Management movement types that do not initiate any activity in the Warehouse Management System have the reference movement type 999. 999 – All non- Inventory transactions and wherever WM is not required

- 2. Other IM movement types are grouped to WM Movement type reference  LE-WM Interface to Inventory Management Reference Movement type --- WM Movement Types 1. IM Movement Types --- WM Reference Movement Type o Non-WM movements are assigned to 999 Movement type so that no more initiation of WM transactions o Grouping of multiple IM movement types into WM Reference Movement types Ex: All kind of external Goods Receipts assigned to 101 2. WM Reference Movement Type --- WM Movement Types o Transfer Requirement creation can be controlled for specific WM movement type o Posting Change Notice Creation can be controlled for specific WM movement type o Immediate TO creation can be controlled

- 3. o Immediate TO creation can be controlled based on Special movement indicator which is assigned to the Material Master in WM1 View o GR date can be determined for specific WM movement type whether it is Current Date/Document date of Material Document/Posting Date of Material Document o Storage Location specific goods movements can be controlled with Storage Location reference - Transfer Requirement: Transfer Requirement Number Number that identifies the transfer requirement within a warehouse. Use The transfer requirement contains information about a planned goods movement in the warehouse. Most planned goods movements are requests sent to other systems, such as the Inventory Management system. Here are some typical examples: ď‚· goods receipts

- 4.  goods issues  stock transfers Configuration: Define Number Ranges: SPRO – LE -> Warehouse Management -> Master Data -> Define Number Ranges -> For Transfer Requirement Control of Manual TR Creation: Allowing Manual TR creation can be controlled at WM Movement Types SPRO – LE -> Warehouse Management -> Activities-> Transfers -> Define Movement Types Control of immediate TR Creation for GoodsMovement: Allowing TR creation based on Goods Movement can be controlled with Reference WM movement type to WM movement type assignment SPRO – LE -> Warehouse Management -> Interfaces-> Inventory Management -> Define Movement Types -> LE-WM Interface to Inventory Management

- 5. TR Creation happens for below Goods Movements which are mostly used by business ď‚· Transfer Posting between IM location to WM location ď‚· Transfer Posting between WM location to IM location ď‚· Goods Issue to Cost Center ď‚· Goods Receipt against Purchase Order