12 piston less pump

- 3. âĒ Pump is a device which converts mechanical energy into hydraulic energy. âĒ Principle: A partial vacuum created when internal parts of pump receives mechanical energy . âĒ Oil is forced into pump due to atmospheric pressure on oil and suction created by pumping element. âĒ Oil is squeezed b/w pump elements which increases pressure of fluid and then is forced out of pump and the cycle continues.

- 4. âĒ Turbo pumps have a reputation for being extremely hard to design to get optimum performance âĒ Low efficiency â ONLY 55% âĒ Weight of pump is high hence Undesirable to use.

- 5. âĒ The turbo pumps used in rocket are very heavy, containing many rotating parts by which there are more frictional losses which more consumption of fuel there by decreasing the efficiency of the engine . âĒ since the rocket has to remain stable in the space, is difficult and require complex methods for it. If this pump gets any fault then its reappearance requires long time. So, there must be such a device which overcomes all the drawbacks of the turbo pump. âĒ The Piston less pump is the solution for the problems faced by using turbo pumps.

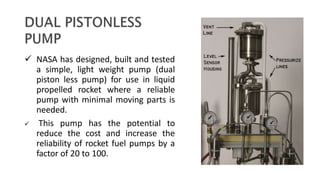

- 6. ïž NASA has designed, built and tested a simple, light weight pump (dual piston less pump) for use in liquid propelled rocket where a reliable pump with minimal moving parts is needed. ïž This pump has the potential to reduce the cost and increase the reliability of rocket fuel pumps by a factor of 20 to 100.

- 7. ïžIt consists of main tank and Two pumping chambers . The pump starts with both chambers filled. ïžEach one being alternately refilled and pressurized . ïžOne chamber is pressurized, and fluid is delivered to the rocket engine from that chamber(Step 1).

- 8. ïž Once the level gets low in one chamber, the other chamber is pressurized;

- 9. ïž Flow is thereby established from both period sides until during a short full flow is established chamber. from Then the other the nearly empty chamber is vented and refilled.

- 10. ïž Finally the cycle repeats. This results in steady flow and pressure. The pump is powered by pressurized gas which acts directly on the fluid

- 11. âĒ DEEP SPACE PROPULSION - NASA has a need for high Power propulsion to land and spacecraft on the moons of Jupiter and beyond. This pump would allow these missions to go forward due to lower weight of the fuel tanks. âĒ X PRIZE VEHICLE FUEL PUMP APPLICATION- For X-prize competitors, a the fuel pump will reduce the cost.

- 12. âĒ All the hardware in the pump consists of pressure vessel so the weight is low. âĒ The pump can be scaled up or down with similar performance and minimal redesign issues. âĒ Low risk development; pump technology has been demonstrated and prototypes have been built and tested. âĒ The manufacturing tolerances need not be tight. âĒ Less moving parts , hence lubrication required is quite low. âĒ Design is simple compared to turbo pumps.

- 13. âĒ They cannot pump to higher then drive pressure(area ratio is 1:1). âĒ They cannot use either a staged combustion or expander cycle. âĒ A gas generator cycle is also difficult to integrate with the piston less pump. âĒ The generated gas must be chemically compatible with both the propellants. âĒ This gas generator lowers the ignition start period of the engine.

- 14. âĒ Static test and fly pump in student rocket with Flometricâs rocket technology. âĒ Along with latest low cost engine designs, pump will make lunch systems more safe, reliable and affordable

- 15. âĒ The most significance of property of Piston less pump that makes them different from that of turbo pump ,is the absence of piston. âĒ This is the most unique technique. In this ,no. of rotating parts is very less as compared to that of turbo pump. Also, itâs installation is very easy. and moreover, it is light weight than turbo pump. So, it has less losses and improves, rather increases efficiency of engine. Also, it is much economical than turbo pump.