207682663-Composite-Material-An-Introduction.pptx

- 1. Introduction to Composite Materials By Bishwaraj Bhattarai Institute Roll No 10/ME/134 Bishwaraj.Bhattarai@Outlook.com Setobaadal@Gmail.com

- 2. Table of Contents 1 #. WHY STUDY COMPOSITE MATERIALS ? 1. Inception and History ŌĆó General Overview, Natural Occurrence and Anthropogenic History 2. Introduction ŌĆó Technical Definition ŌĆó Composition 3. Classification ŌĆó Based on Matrix Phase ŌĆó Based on Reinforcements 4. Mechanical Characterization ŌĆó Rule of Mixture and Loading Orientation ŌĆó Estimation of Various Properties 5. Advantages of Composite Materials 6. Disadvantages of Composite Materials 7. Conclusion

- 3. 2 Why Study Composite Materials ??? Lets take a closer look at our livesŌĆ”.

- 4. 3 Why Study ŌĆ”contd. ŌĆó Composites make a great proportion of most of the materials we use in our daily lives ŌĆó The use is ever increasing which makes it a must to understand and explore these materials THATŌĆÖS WHY ŌĆ”ŌĆ”.

- 5. 1. Inception and History of Composite Materials 4 ŌĆó ŌĆ£Composite MaterialŌĆØ = Combination of two materials ŌĆó Natural Occurrences 1. Trees = Cellulose Fibers + Lignin (natural Polymer) 2. Muscles 3. Bones 4. Silky thread made by spider ŌĆó Anthropogenic History ’ā╝ Wood is the oldest known composite used by human beings ’ā╝ Straw Bricks ŌĆō as construction material, ~ 10000 BC ( Ashby et al) ’ā╝ Modern development began before World War II with requirement of strong but light material ’ā╝ Glass Fiber Reinforced Plastic was the first commercial Composite used in Havilland Mosquito Bomber aircraft of Royal British Navy force

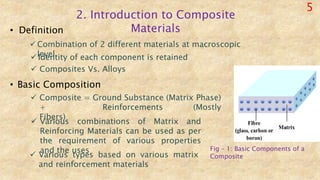

- 6. 2. Introduction to Composite Materials 5 ŌĆó Definition ’ā╝ Combination of 2 different materials at macroscopic level ’ā╝ Identity of each component is retained ’ā╝ Composites Vs. Alloys ŌĆó Basic Composition ’ā╝ Composite = Ground Substance (Matrix Phase) + Reinforcements (Mostly Fibers) Fig ŌĆō 1: Basic Components of a Composite ’ā╝ Various combinations of Matrix and Reinforcing Materials can be used as per the requirement of various properties and the uses ’ā╝ Various types based on various matrix and reinforcement materials

- 7. 6 3. Classification of Composite Materials A. Based on Matrix Phase: Polymer/Metal/Ceramic 1. Polymer Matrix Composite, PMC ŌĆó Matrix is made from a Polymer like Resins ŌĆó The first commercial composite, Glass Fiber, was a PMC made with Phenolic Resin ŌĆó May be a. Thermosetting ~ Epoxy Resin OR b. Thermoplastic ~ Polycarbonate, PVC, Nylon, Polystyrene ’ā╝ Light Weight ’ā╝ Easy Processing ’ā╝ Excellent Mechanical Properties ’āś Extensive use in Automobile and Aeronautical Industries 2. Metal Matrix Composite, MMC ŌĆó Use metals like Aluminum, Magnesium, Iron, Cobalt etc. as matrix phase ’ā╝ Provide additional Strength, Fracture Toughness and Stiffness than PMC ’āś Popular in Mobile Phone industries

- 8. 3.A Classification/Matrix Phase ŌĆ” contd. 3. Ceramic Matrix Composite, CMC ŌĆó Use Ceramic materials as the matrix phase and reinforce with short fibers derived from Silicon Carbide, Boron Nitride, etc. ’ā╝ High Melting Point ’ā╝ Stability at elevated temperature ( ~ 1500 oC ) ’ā╝ Corrosion Resistant ’ā╝ High Compressive Strength 7 ’āś Favorite choice for working in high temperature environment X However they are quite brittle compared to PMCs B. Classification Based on Reinforcement Materials: Fibers/Particulates/Flakes/Whiskers 1. Fiber Reinforcement ŌĆó Fibers made from various materials are placed within the matrix phase to form a composite of desired strength/properties ŌĆó Fibers form the major load carrying element and are most common reinforcement

- 9. 3.B Classification/By Reinforcement/Fibers ŌĆ”. Contd. 8 3.B.1 Fiber Reinforcement: ’ü▒ Types of Fiber Reinforcement A. Continuous/Long Fiber ŌĆó Long, continuous and unbroken fibers are used with L/D > 100 ŌĆó Most common type of composite materials ŌĆó Fibers may be oriented unidirectional or bidirectional ’ā╝ Better ŌĆśimpact resistance and rigidity at elevated, sub zero temperatures ’ā╝ Modulus retention at elevated temperature ’ā╝ Creep resistance ’ā╝ Dimensional stability during solidification (thermoplastics used as matrix phase) B. Short/Chopped Fibers ŌĆó Chopped or small pieces of fibers are used instead of long, continuous fibers ŌĆó L/D ratio is within 100 ’ü▒Common Fiber Materials A. Carbon/Graphite B. Glass C. Aramid D. Boron Fig-2: Fiber Composite

- 10. 3.B.1 Classification/Based on Reinforcement/Fibers/ Common Fiber MaterialsŌĆ”ŌĆ”. Contd. 9 A. Carbon/Graphite Fibers ŌĆó Fibers are made from carbon/graphite material, commonly derived from Polyacrylonitrile ’ā╝ Excellent fatigue resistance and do not undergo stress rupture like glass fibers ’ā╝ High electrical conductivity, due to conductive nature of Carbon, thus used for applications requiring good electrical properties B. Glass Fiber ŌĆó Glass is the most common reinforcement material for PMC ŌĆó Common variants are E-glass, R-glass, S-glass, D-glass, ECR-glass etc. ŌĆó Configuration may be Roving, Sheet Moulding, Woven Roving, Chopped Strand Mat etc. ’ā╝ High Tensile Strength X Lower Modulus compared to other fibers C. Aramid Fiber ŌĆó Kevlar is a common aramid fiber composite ’ā╝ Highest strength to weight ratio among all commercial composites ’ā╝ Similar tensile strength but at least twice modulus compared to glass fibers ’ā╝ High Toughness X Lower compression strength, poor adhesion to matrix

- 11. 1 0 3.B.1 Classification/By Reinforcement/Fiber/Fiber Materials ŌĆ”.. Contd. D. Boron Fibers ŌĆó Has been in use much before the use of Carbon fibers began ŌĆó High cost led to gradual reduction in their except for specific purposes ’ā╝ Similar tensile strength to glass fibers but very high modulus, up to 5 times higher ’ā╝ Composite has higher stiffness 3.B.2 Particulate Reinforcement ŌĆó Reinforcement in form of particles which are of order of few microns in diameter ŌĆó Use of particles increases modulus and decreases ductility of matrix material ŌĆó Load is shared by both particle and matrix, majority by particles ’āś E.g. Automobile type Carbon Black (particulate)+Rubber (matrix) Fig ŌĆō 3: Particulate

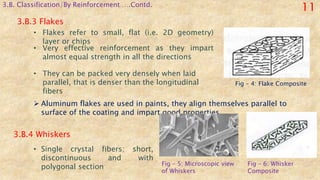

- 12. 11 3.B. Classification/By Reinforcement ŌĆ”.Contd. 3.B.3 Flakes Fig ŌĆō 4: Flake Composite ŌĆó Flakes refer to small, flat (i.e. 2D geometry) layer or chips ŌĆó Very effective reinforcement as they impart almost equal strength in all the directions ŌĆó They can be packed very densely when laid parallel, that is denser than the longitudinal fibers ’āś Aluminum flakes are used in paints, they align themselves parallel to surface of the coating and impart good properties 3.B.4 Whiskers ŌĆó Single crystal fibers; short, discontinuous and with polygonal section Fig ŌĆō 5: Microscopic view of Whiskers Fig ŌĆō 6: Whisker Composite

- 13. 12 4. Mechanical Characterization : Composites 4.1 Introduction ŌĆó Estimation of mechanical properties of composite is a bit complex compared to metals as they are anisotropic and the properties vary with directions ŌĆó Structural analysis involves more parameters (like Stiffness/Strength Constants) than the analysis of metals. ŌĆó Mechanical characterization of composites is still under development, with many existing methods under debate. 4.2 Loading Orientation and Rule of Mixture A. Loading Orientation ŌĆó Load may be ŌĆó Iso Strain : Load aligned with fibers OR ŌĆó Iso Stress : Load transverse to the fibers Fig ŌĆō 7: (a) Iso Strain Load (b) Iso

- 14. 13 4.2 Mechanical Characterization ŌĆ”. Contd. B. Rule of Mixture ŌĆó ItŌĆÖs an approach to estimate the mechanical properties of composite materials ŌĆó Property of composite is the volume weighed average of the properties of the constituents matrix and the dispersed phases ŌĆó Some of the properties may depend on loading direction and vary for Iso Strain and Iso Stress conditions, while other properties are same for both the loading conditions 4.3 Estimation of various Mechanical Properties of the Composites 1. Density dc = dm . Vm + df . Vf dc ,dm,df ŌĆō densities of the composite, matrix and dispersed phase respectively; Vm ,Vf ŌĆō volume fraction of the matrix and dispersed phase

- 15. 14 4.3 Mechanical Characterization/Mechanical Properties ŌĆ”ŌĆ” Contd. 2. Coefficient of Thermal Expansion A. Iso-Strain/Parallel to fibers ╬▒c =( ╬▒m . Em .Vm + ╬▒f . Ef . Vf ) / (Em . Vm + Ef Vf ) ╬▒c , ╬▒m , ╬▒f ŌĆō Coefficient of thermal expansion of composite in longitudinal direction, matrix and dispersed phase (fiber) respectively; Em , Ef ŌĆō Modulus of elasticity of matrix and dispersed phase (fiber) respectively. B. Iso-Stress/Transverse to Fibers ╬▒ct = (1+╬╝m) ╬▒m . Vm + ╬▒f . Vf ╬╝m - PoissonŌĆÖs ratio of matrix ╬▒ct ŌĆō Coefficient of thermal expansion in transverse direction

- 16. 15 4.3 Mechanical Properties ŌĆ”. Contd. 3. Modulus of Elasticity A. Iso Strain Condition Ec = Em . Vm + Ef . Vf B. Iso Stress Condition 1/Ect = Vm/Em + Vf/Ef C. Short Fibers Ecl = ╬Ęo . ╬Ęl . Vf . Ef + Vm . Em ╬Ęl = 1 ŌĆō 2 / (╬▓L) . tan h(╬▓L / 2 ) ╬▓ =[ 8Gm / ( Ef . D2 . ln ( 2 R/ D))]1/2 Ef - Modulus of elasticity of matrix materials ╬Ęo - 0.0 align in transverse direction Gm - Shear modulus of matrix material ╬Ęo - 1/5 random orientation in any direction ( 3D ) ╬Ęl - Length correction factor ╬Ęo - 3/8 random orientation in any direction (2D) L - Fibers length ╬Ę - ┬Į bi- axial parallel to the fibers

- 17. 16 4.3 Mechanical Properties ŌĆ”ŌĆ” Cont. 4. Sheer Modulus Gc = Gf . Gm / ( Vf . Gm + Vm . Gf ) Gf - shear modulus of elasticity of fiber material Gm - shear modulus of elasticity of matrix material Gc - shear modulus of elasticity of composite 5. PoissonŌĆÖs Ratio ┬Ą = Vf . ┬Ąf + Vm . ┬Ąm ┬Ąf - PoissonŌĆÖs ratio of fiber materials ┬Ąm - PoissonŌĆÖs ratio of matrix materials ┬Ą - PoissonŌĆÖs ratio of composite

- 18. 17 4.3. Mechanical Properties ŌĆ”ŌĆ”. Contd. 6. Tensile Strength A. Long Fiber Žāc = Žām . Vm + Žāf . Vf Žāc , Žām, Žāf - tensile strength of the composite ,matrix and dispersed phase (fiber) respectively B. Short Fiber ’é¦ Žāc = Žām . Vm + Žāf . Vf . ( 1 ŌĆō Lc/ 2L ) for length less then critical length, Lc ’é¦ Žāc = Žām*Vm + L* Žäc*Vf/d for length more than critical length L c = Žāf * d / Tc d - diameter of fiber Tc - shear strength of the bond between the matrix and dispersed phase L - length of the fiber

- 19. 18 5. Advantages of Composite Materials ’ā╝ High Strength to Weight Ratio ’ā╝ Light Weight ’ā╝ Design Flexibility, to achieve desired stiffness, strength and manufacturing requirements ’ā╝ Complex shapes are easily accomplished ’ā╝ Fire Resistance ’ā╝ Chemical and weathering Resistance ’ā╝ Resistance to fatigue damage with good damping properties ’ā╝ Low thermal conductivity

- 20. 19 5. Disadvantages ’āś High Manufacturing Cost. A typical finished composite may cost in between 10-15 times (or even more) the cost of material being used. ’āś Synthetic fibers have low melting point and thus high temperature operation is not feasible for those type of composite ’āś Repairs of composites is very difficult and complicated, unlike metal based components ’āś Sometimes, critical flaws and cracks in the composite structure may go unnoticed 6. Conclusion ŌĆó A field of heave research and development ŌĆó Development of new types and obtaining the desired properties is the main focus ŌĆó Attempts are being made to reduce the manufacturing cost

- 21. THANK YOU !!!

![15

4.3 Mechanical Properties ŌĆ”. Contd.

3. Modulus of Elasticity

A. Iso Strain Condition

Ec = Em . Vm + Ef . Vf

B. Iso Stress Condition

1/Ect = Vm/Em + Vf/Ef

C. Short Fibers

Ecl = ╬Ęo . ╬Ęl . Vf . Ef + Vm . Em

╬Ęl = 1 ŌĆō 2 / (╬▓L) . tan h(╬▓L / 2 )

╬▓ =[ 8Gm / ( Ef . D2 . ln ( 2 R/ D))]1/2

Ef - Modulus of elasticity of matrix materials ╬Ęo - 0.0 align in transverse

direction

Gm - Shear modulus of matrix material ╬Ęo - 1/5 random orientation in

any direction ( 3D )

╬Ęl - Length correction factor ╬Ęo - 3/8 random orientation in

any direction (2D)

L - Fibers length ╬Ę - ┬Į bi- axial parallel to the fibers](https://image.slidesharecdn.com/207682663-composite-material-an-introduction-221212034915-1d070e17/85/207682663-Composite-Material-An-Introduction-pptx-16-320.jpg)