22d2optimalassemblylinebalancing222 110829065724-phpapp02

- 1. OPTIMAL ASSEMBLY LINE BALANCING By SUNIL KUMAR K.P. IEM, BMSCE.

- 2. Introduction • The manufacturing assembly line balancing was first introduced in the early 1900’s. • There are 2 types of assembly line balancing problems. -SALBP-1. -SALBP-2. • The tabu search (TS) is one of the most powerful AI search techniques,which is used to solve the assembly line problems.

- 3. What is Assembly Line Balancing (ALB)? ALB is the procedure to assign tasks to workstations so that: • Precedence relationship is complied with. • No workstation takes more than the cycle time to complete. • Operational idle time is minimized.

- 4. Definition of ALB: • An Assembly line is a sequence of work stations connected together by material handling. • Goal of ALB: -minimize number of work stations. -minimize work load variance. -minimize idle time. -maximize the line efficiency.

- 5. Assembly line Principles: • Division of labor principle. • Interchangeable parts principle. • Material workflow principle. • Line pacing principle.

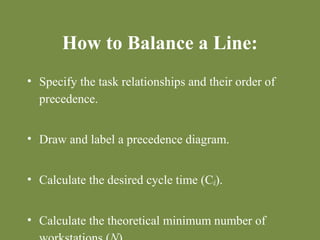

- 6. How to Balance a Line: • Specify the task relationships and their order of precedence. • Draw and label a precedence diagram. • Calculate the desired cycle time (Cd). • Calculate the theoretical minimum number of workstations (N).

- 7. How to Balance a Line(cont’d) • Group elements into workstations recognizing cycle time & precedence. • Evaluate the efficiency of the line (E). • Repeat until desired line efficiency is reached

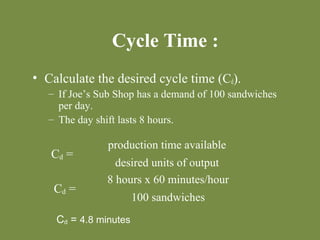

- 8. Cycle Time : • Calculate the desired cycle time (Cd). – If Joe’s Sub Shop has a demand of 100 sandwiches per day. – The day shift lasts 8 hours. Cd = production time available desired units of output Cd = 8 hours x 60 minutes/hour 100 sandwiches Cd = 4.8 minutes

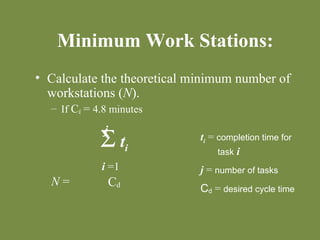

- 9. Minimum Work Stations: • Calculate the theoretical minimum number of workstations (N). – If Cd = 4.8 minutes N = S ti Cd j i =1 ti = completion time for task i j = number of tasks Cd = desired cycle time

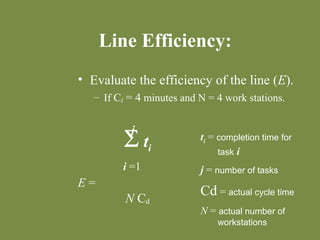

- 10. Line Efficiency: • Evaluate the efficiency of the line (E). – If Cd = 4 minutes and N = 4 work stations. E = j S ti i =1 N Cd ti = completion time for task i j = number of tasks Cd = actual cycle time N = actual number of workstations

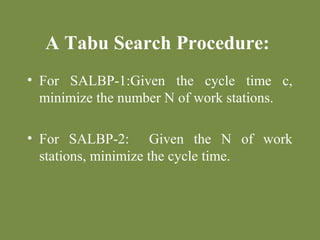

- 11. A Tabu Search Procedure: • For SALBP-1:Given the cycle time c, minimize the number N of work stations. • For SALBP-2: Given the N of work stations, minimize the cycle time.

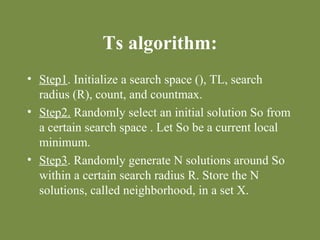

- 12. Ts algorithm: • Step1. Initialize a search space (), TL, search radius (R), count, and countmax. • Step2. Randomly select an initial solution So from a certain search space . Let So be a current local minimum. • Step3. Randomly generate N solutions around So within a certain search radius R. Store the N solutions, called neighborhood, in a set X.

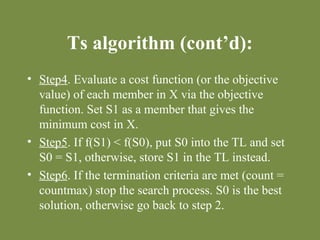

- 13. Ts algorithm (cont’d): • Step4. Evaluate a cost function (or the objective value) of each member in X via the objective function. Set S1 as a member that gives the minimum cost in X. • Step5. If f(S1) < f(S0), put S0 into the TL and set S0 = S1, otherwise, store S1 in the TL instead. • Step6. If the termination criteria are met (count = countmax) stop the search process. S0 is the best solution, otherwise go back to step 2.

- 14. Case Study:a company of the Fiat group • a company of the Fiat group, plays a leading role in the production of industrial Vehicles and diesel engines. • This group includes Lancia special vehicles, Unic, & Magirus. • it manufactures many types of industrial vehicles, fire fighting & military vehicle

- 15. The Solution: By Fiat group. • Guided definition of assembly constraints based on product characteristics. • Establishment of optimal sequence for assembly lines, using appropriate GA. • Easy & quick modeling of new products and implementation for new plants. • The simple and user-friendly interface allows for visual review of planning effectiveness.

- 16. Conclusion: • Simply Assembly Line Balancing is a valid method to optimize assembly lines. By using tabu search we can easily optimize the ALB problems. balanced assembly line help to increase the productivity of organization.

- 17. THANK YOU

- 18. References: • [1] ISSN 1750-9653, England, UK International Journal of Management Science and Engineering Management Vol. 3 (2008) No. 1, pp. 3-18. • [2] www.springerlink.com, SPRINGLERLINK. Istanbul technical University, Istanbul turkey(16/02/09).

Editor's Notes

- Next the desired cycle time must be calculated. To calculate desired cycle time, you divide the production time available by the number of units desired. If Joe’s Sub Shop has a demand of 100 sub sandwiches per day, and the day shift is 8 hours long, what is the desired cycle time? The desired cycle time is 4.8 minutes. This means that the sandwich can only stay 4.8 minutes at each workstation in order to meet Joe’s demand of 100 sandwiches per day.

- Next the theoretical minimum number of workstations must be calculated. If Joe’s Sub Shop has a desired cycle time of 4.8 minutes, what is the theoretical minimum number of workstations possible?

- This is the equation for calculating the assembly line efficiency. It is the sum of the task times divided by, the number of workstations times the actual cycle time. The actual cycle time is the maximum workstation time on the line. The actual cycle time for this problem is 4 minutes.

![References:

• [1] ISSN 1750-9653, England, UK

International Journal of Management

Science and Engineering Management Vol.

3 (2008) No. 1, pp. 3-18.

• [2] www.springerlink.com,

SPRINGLERLINK. Istanbul technical

University, Istanbul turkey(16/02/09).](https://image.slidesharecdn.com/22d2optimalassemblylinebalancing222-110829065724-phpapp02-140901013146-phpapp02/85/22d2optimalassemblylinebalancing222-110829065724-phpapp02-18-320.jpg)