3 d printing

- 2. Introduction- New possibilities in 3D printing may open up a whole new chapter of opportunities for pharmaceutical research and bio-technology applications. There are a number of ways it could be used — drug dosage forms, supporting delivery, or helping to research cures. 3D printing has been around for many years; predominantly been used in manufacturing. This type of printing, also called stereo lithography, can create almost any object by fusing different materials, layer by layer, to form a physical version of a digital 3D image.

- 3. The 3D printing concept of custom manufacturing is exciting to nearly everyone. This revolutionary method for creating 3D models with the use of inkjet technology saves time and cost by eliminating the need to design; print and glue together separate model parts. Now, you can create a complete model in a single process using 3D printing. Pharmaceutical drug research and development could be improved drastically by 3D printing. Rather than printing objects made out of plastic or metal, imagine printing pills or human organs and tissue.

- 4. Physical prototypes realized in shape, texture and color go far beyond drawings or computer models to communicate your vision in a dramatic way. Through 3D printing before the product is ever produced, people can touch it; feel it; turn it left, right and upside down; and look inside. they can test it, operate it and fully evaluate it-long before the finished product is brought to market. FDA recently approved a 3D-printed drug product in August 2015, which is indicative of a new chapter for pharmaceutical manufacturing.

- 5. 3D Printing will- • Improve communication within the product development organization; • Shorten design cycles; • Put superior products on the market ahead the competition; • Stretch R&D dollars; • Improve accuracy; • Eliminate costly mistakes; • Trigger unexpected ideas; • Drive innovation and quality; and Improve collaboration among engineering, sales, marketing and the executive team.

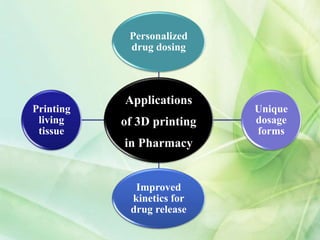

- 6. 3D printing is now enabling much more innovation in this area, with many researchers investigating the kinetic properties of shapes that were once very difficult to manufacture. 3D printed pyramid-shaped tablets, for instance, may gain popularity as a format for fast-acting remedies because they have been found to release drugs more rapidly than standard cylinder- shaped pills.

- 8. Traditional manufacturing vs. 3D printing

- 9. Applications of 3D printing in Pharmacy Personalized drug dosing Unique dosage forms Improved kinetics for drug release Printing living tissue

- 10. 3D printing will also strongly impact pharma business by- Changes to R & D – Developing a new drug costs upward of US$4 billion. Even after extensive testing in the lab and on animals only a handful of drugs are successful enough to go on to clinical trials in humans. Astonishingly, the failure rate of drugs in clinical trials is 90% because humans and animals often respond differently. 3D printing can solve this problem. Bio printing has already had some success. Last year, a two-year-old girl in Illinois, born without a trachea, received a windpipe built with her own stem cells.

- 11. It turns out that the surface area-to-volume ratio is an important property and determinant in kinetics of drug release. A pyramid and standard cylinder are not created equal—with the pyramid able to deliver drug more expediently based on kinetic studies. The take- away point is that the one-size-fits-all approach is not optimal for patients who require continuous adjustments in their dosage.

- 12. A technique using 3D printing referred to as “hot melt extrusion” has developed to produce many odd shaped medications which are quite difficult to manufacture using standard production techniques. The true advantage of hot melt extrusion is that such odd shaped medications demonstrate improved kinetics for drug release.

- 13. Since we know that some patients require medications that are faster acting, while others need medications to be released more gradually over a longer period of time, 3D printing offers one the ability to customize medications for individual patient needs.

- 14. Another application of 3D printing in the biomedical field is that of creating limbs and other body parts out of metal or other materials to replace lost or damaged limbs. 3D printing is being used to design and produce custom prosthetic limbs to meet the patient’s exact requirements. By scanning the patient’s body and existing bone structure, designers and engineers are able to re- create the lost part of that limb.

- 15. FDA approves the first 3D printed drug product The US Food and Drug Administration (F.D.A) has given the go-ahead to the world's first 3D-printed drug, Spritam, which is designed to treat seizures brought on by epilepsy in adults and children. The drug was developed using Pennsylvania-based Aprecia Pharmaceuticals' proprietary .

- 16. Future trends • 3D printing is expected to play an important role in the trend toward personalized medicine, through its use in customizing nutritional products, organs, and drugs. • 3D printing is expected to be especially common in pharmacy settings. The manufacturing and distribution of drugs could conceivably be replaced by emailing databases of medication formulations to pharmacies for on-demand drug printing. This would cause existing drug manufacturing and distribution methods to change drastically and become more cost-effective.

- 17. Conclusion •Reduces time •Enables delocalization of manufacturing. •Create opportunities for improving the safety, efficacy, and accessibility of medicines. •Drug testing on 3D-printed tissues will replace animal trials •Enables customization: The era of “mass customization”

- 18. •New era of “social manufacturing”. •“On demand’’ process: raw materials, or feedstock, need to be close at hand. •Internet community + cloud + 3D Printing = next big thing! •Low cost might play a bigger role in developing countries. •Used in several sectors, allows innovation. •Can have an impact like any other technology . •Might change the future.