3 D Visual Avis Project

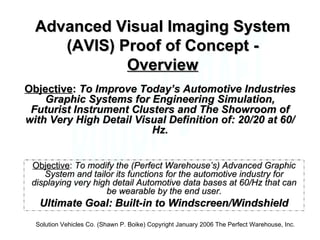

- 1. Advanced Visual Imaging System (AVIS) Proof of Concept - Overview Objective : To modify the (Perfect Warehouse’s) Advanced Graphic System and tailor its functions for the automotive industry for displaying very high detail Automotive data bases at 60/Hz that can be wearable by the end user. Ultimate Goal: Built-in to Windscreen/Windshield Solution Vehicles Co. (Shawn P. Boike) Copyright January 2006 The Perfect Warehouse, Inc. Objective : To Improve Today’s Automotive Industries Graphic Systems for Engineering Simulation, Futurist Instrument Clusters and The Showroom of with Very High Detail Visual Definition of: 20/20 at 60/Hz.

- 2. Advanced Visual Imaging System (AVIS) Proof of Concept - Overview AGENDA Current Market Analysis Problem Statement-Current Limits AVIS Advanced Technology Applications (CAVE, Instrument Cluster, Showrooms) Advantages & Technology Improvements Cost (Budget Price Estimate “BPE”) & Integrated Schedule (IS) Risk to Payoff Estimate Ultimate Future Application Copyright January 2006 The Perfect Warehouse, Inc.

- 3. Current Simulator Systems (CAVE, ICE Lab…) Development Time & Costs (ROM) Auto Industry (CAVE Type) Time: Costs: Aerospace Industry Simulators Avg. Time: Costs: Future Combat Systems (ICE Lab Type) Time: Costs: NASCAR- Simulators Time: Costs: Copyright January 2006 The Perfect Warehouse, Inc.

- 4. Current Instrument Clusters Time & Costs (ROM) Auto Industry IP Clusters Time: Costs: Aerospace Industry Glass Cockpit Time: Costs: Future Combat Systems Glass Cockpit Time: Costs: COTS (Auto Store Off-The-Shelf): Time: Costs: Copyright January 2006 The Perfect Warehouse, Inc.

- 5. DATA BASES for Automotive Industry The data bases that this system will run will consist of In house NURBS CGI renderings and CAD / CAM drawings of vehicles converted to run on IG through the use of newly developed cross compilers Other off the shelf models we have in stock Copyright January 2006 The Perfect Warehouse, Inc.

- 6. Examples of: Off-the-shelf data base models approx 60,000 textured polygons each total polygon count over 240,000. ( Limitation is: maxes out cots real time capacity of 160,000 at 1/60 th of a second update rate). HUMMER CORVETTE SABB CADILLAC Copyright January 2006 The Perfect Warehouse, Inc.

- 7. OFF THE SHELF – HUMMER 60,000 TEXTURED POLYGONS Copyright January 2006 The Perfect Warehouse, Inc.

- 8. OFF THE SHELF - CORVETTE 60,000 TEXTURED POLYGONS Copyright January 2006 The Perfect Warehouse, Inc.

- 9. OFF THE SHELF - SAAB 60,000 TEXTURED POLYGONS Copyright January 2006 The Perfect Warehouse, Inc.

- 10. OFF THE SHELF - CADILLAC 60,000 TEXTURED POLYGONS Copyright January 2006 The Perfect Warehouse, Inc.

- 11. 4 – 10 MODELS NEEDED ON SHOW ROOM FLOOR These Models Look Good When Viewed From This Distance You Need About 10 Times The Polygons For 20/20 Vision Close Up Therefore 600,000 Polygons Each 2,400,000 Polygons Needed For 4 Models Current Off The Shelf (COTS) Needs To Be 15 Times Faster Than It Is Now To Produce 4 Models 6,000,000 Polygons Will Render 10 Cars In A Show Room Floor At 20/20 Vision – COTS Limitation Lacks Capability By 37.5 Times Copyright January 2006 The Perfect Warehouse, Inc.

- 12. IG Primitive Capabilities Host Interrupts to IG controls the IG primitives 200,000 Moving Models can be controlled USB 2.0 interface to host computer, interrupt driven Texture Map control Points and Polygons control Translucency Light points Light sources Copyright January 2006 The Perfect Warehouse, Inc.

- 13. RECOMMENDED SYSTEM APPROACH Copyright January 2006 The Perfect Warehouse, Inc.

- 14. Simple Requirements (Chg Title) To have a wearable Eye Mounted System for the user to view the resulting data base with the same detail as the human eye can focus with 20/20 vision in a “CAVE” type of environment To update the entire display at 60 Hz including generation of the 3D graphics images from source input to the virtual displayed image To track the user’s eye and head movements in 3D Space as large as a warehouse or as small as a driver compartment. Copyright January 2006 The Perfect Warehouse, Inc.

- 15. To Be: Short Film to demonstrate the true requirements of real time “Cave” DEALERSHIP SHOW ROOM 4 cars to 10 cars WALK AROUND WITH CAMERA OPEN UP DOORS OF CARS SIT IN CAR TURN ON CAR FUNCTIONS ZOOM INTO DIFFERENT DETAILS OF CAR Copyright January 2006 The Perfect Warehouse, Inc.

- 16. What needs to be built or modified Need to satisfy the requirements of last 2 slides Image Generation System capable of rendering images in real time Display System capable of projecting image of cars to meet 20/20 vision Data base set of 4 to 10 cars in a show room Copyright January 2006 The Perfect Warehouse, Inc.

- 17. The existing Image Generator and Display System with Tracker System (IGDST System) consists of 5 major modules: Advanced Image Generator Advanced Display System Advanced Tracker Cross Compilers Data Bases Copyright January 2006 The Perfect Warehouse, Inc.

- 18. IGDST System Image Generator Entire System Can be worn on body Up to 80,000,000 textured polygons at 60/hz 6 – 20 million textured polygons for 4x6 inch unit 24 – 80 million textured polygons for 9 inch unit Display System Display resolution produces 20/20 vision Full 360 degrees field of view Operations in very small to very large areas Tracker System 360 deg in yaw 180 deg in pitch Cross Compilers to Data Sets Data Bases Level of Detail for real time rendering Conversion of Nurbs and CAD/CAM Data Sets Copyright January 2006 The Perfect Warehouse, Inc.

- 19. Image Generator Phased Approach Built upon 30 years of research and development Several previous designs Low risk New System is FPGA Based, old system IC chip based Host Computer can be on IG board instead of reverse 5 Years of Design already accomplished, 2 more years to go before completion. Built upon success of working system 9 years ago Now at the schematic detailed design stage Software compiler at the detailed design stage More features then ATI and NVidia Need 16 ATI chips to render just the anti-aliasing this system accomplishes Do not need to go through the OpenGL or Direct3D architectures to talk to IG Hardware. You can interface directly with the IG from host through an interrupt driven system. 200,000 moving models processing in 3ms. The best ATI and NVidia based systems can only produce 100,000 front facing polygons, this design at its minimum configuration is 600 times faster at 6,000,000 front facing polygons. Next 2 years of Image Generator Project 8 months: Build Prototype 1 – 6 to 20 million polygons on 9”x 9” board 4 months: Build Prototype 2 – shrink to 4” by 6” board 12 months: Build Prototype 3 – UP TO 80 million polygons on 9”x9” board Copyright January 2006 The Perfect Warehouse, Inc.

- 20. Display System Fast Prototype Already Constructed Patent Pending Unlimited Field of View for immediate fovea area of interest – 20/20 vision achieved Unlimited Field of View for Peripheral Vision Copyright January 2006 The Perfect Warehouse, Inc.

- 21. Cross Compilers For IG Initial Layer to talk to new IG Second Layer to talk to OpenGL generated data bases Second Layer to talk to Direct 3D generated data bases Third Layer to talk directly to Known 3D Formats through Second Layer or directly to Initial Layer Copyright January 2006 The Perfect Warehouse, Inc.

- 22. Tracker System No magnetic limitations Line of sight tracking for Head Movement Eye Tracking with respect to Head Movement Full 360 degrees of tracking in the Yaw 180 degrees plus tracking in the Pitch Copyright January 2006 The Perfect Warehouse, Inc.

- 23. Final Analysis Schedule Funding Profile Risks? Benefits? Copyright January 2006 The Perfect Warehouse, Inc.

- 24. SCHEDULE 2 year plan to complete all tasks. Advanced Image Generator Advanced Display System Advanced Tracker Cross Compilers Data Bases Copyright January 2006 The Perfect Warehouse, Inc.

- 25. SCHEDULE ADVANCED DISPLAY SYSTEM MONO AND STEREO VIEWING COMPUTER DISTORTION CORRECTION OPTICS BEAM SPLITTER LENS SERVO DEVELOPMENT COMFORTABLE HEAD MOUNT 3 TYPES OF DISPLAY INFORMATION OUT THE CAR IN THE CAR MOVE WITH EYE Copyright January 2006 The Perfect Warehouse, Inc.

- 26. SCHEDULE ADVANCED TRACKER HEAD TRACKER EYE TRACKER Copyright January 2006 The Perfect Warehouse, Inc.

- 27. SCHEDULE ADVANCED IMAGE GENERATOR SHOW PAST 5 YEARS SHOW NEXT 2 YEARS Copyright January 2006 The Perfect Warehouse, Inc.

- 28. SCHEDULE CROSS COMPILERS NURBS CONVERSION CAD/CAM CONVERSION COMPILER TO NEW IG COMPILER TO OPENGL COMPILER TO DIRECT 3D (OPTIONAL) Copyright January 2006 The Perfect Warehouse, Inc.

- 29. SCHEDULE DATA BASE FIRST – COMPILE TO NEW IG FORMATS CAD/CAM DATA NURBS DATA SECOND - CONSTRUCT HIGHER LEVEL OF DETAIL TO MEET 20/20 VISION OF NEW DISPLAY SYSTEM (AVERAGE 10 TIMES MORE DATA REQUIRED) Copyright January 2006 The Perfect Warehouse, Inc.

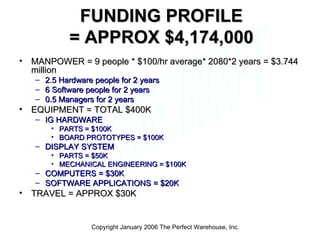

- 30. FUNDING PROFILE = APPROX $4,174,000 MANPOWER = 9 people * $100/hr average* 2080*2 years = $3.744 million 2.5 Hardware people for 2 years 6 Software people for 2 years 0.5 Managers for 2 years EQUIPMENT = TOTAL $400K IG HARDWARE PARTS = $100K BOARD PROTOTYPES = $100K DISPLAY SYSTEM PARTS = $50K MECHANICAL ENGINEERING = $100K COMPUTERS = $30K SOFTWARE APPLICATIONS = $20K TRAVEL = APPROX $30K Copyright January 2006 The Perfect Warehouse, Inc.

- 31. RISKS? Last 2 years of development runs in parallel with system, but we are in the detailed schematic design stage and we have built 3 previous IG systems in the past 30 years. So risks are at a minimum Copyright January 2006 The Perfect Warehouse, Inc.

- 32. BENEFITS Auto Industry can have influence on the next 2 years of processing 6 to 20 million polygons wearable system at 1/60 th second update rate One 9 inch board system capable of producing up to 80,000,000 polygons Anti-aliased system 6,000 by 4,000 resolution processing of display 1,500 by 1,000 in final pixel domain after Anti-aliased 600 to 2,000 times faster than any COTS system on the market today Full control of Image Generator Do not have to process through OpenGL or Direct 3D Do not have to plug into PCI slot (limited bandwidth) Copyright January 2006 The Perfect Warehouse, Inc.

- 33. POTENTIAL APPLICATIONS CAVE APPLICATION CUT-A-WAYS SHOWING THE DETAILS INSIDE MANY DISPLAYS IN AUTO - DIFFERENT CONFIGURATIONS ARE FLEXIBLE/MOVEABLE UNLIMITED INTERACTIVE WITHOUT THE USE OF SPECIAL HARDWARE BUTTONS OR TOUCH SCREENS BETTER SITUATIONAL AWARENESS CAMERAS CAN PROJECT BLIND SPOTS UNLIMITED USE OF REAR VIEW MIRRORS PATH WAYS IN THE STREET COLLISION AVOIDANCE WITH HEAD UP DISPLAY SHOWING WHERE POTENTIAL ACCIDENTS COULD OCCUR WARNING SYSTEM THAT IS 3D VISUAL Copyright January 2006 The Perfect Warehouse, Inc.

Editor's Notes

- Objective: To modify the Perfect Warehouse’s Advanced Graphic System and tailor its functions for the automotive industry for displaying very high detail Automotive data bases at 60/Hz that can be wearable by the end user to view automotive industry products through an advanced display system.