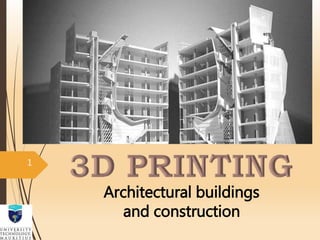

3d Printing

- 2. 3D Printing in Architecture 2 Time Consuming 5 times Faster By hand With 3D printer

- 3. ď‚´ 3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. ď‚´ In an additive process an object is created by laying down successive layers of material until the entire object is created. 3

- 4. ď‚´ Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object. ď‚´ 3D printing allows to easily test many concepts and quickly identify potential structure issues, which would be harder to spot on computer simulations. 4

- 5. Benefits  3D printing saves time in the early design and creation phases by reducing the lead-time for model production and allowing quick tests of concepts and iterations. 5 1. Higher productivity Take several days Deliver results in hours There’s productivity gain.

- 6. 2. Lower Production Costs ď‚´ To assess volumes and general structure of the building, they need to be 3D printed using a single plastic material and a small number of colours, thus keeping the production costs to a minimum. ď‚´ The 3D printer manufacturer Stratasys claims that modeling costs can be reduced up to 75% by using 3D printing. 6 Benefits

- 7. 7  Charles Ovry, founder of Laser Graphic Manufacturing, with a model of a resort in Vail (town in United States). “We used to take two months to build $100,000 models, but now they cost about $2,000.”

- 8. ď‚´ It is possible to create architectural models of complex structures. ď‚´ MX3D recently work to 3D print an actual metal bridge in Amsterdam. They have used an innovative 3D printing system, which extrudes melted metal, which are almost impossible to produce by hand. 8 Benefits

- 9. 9