3.-Invar.pdf

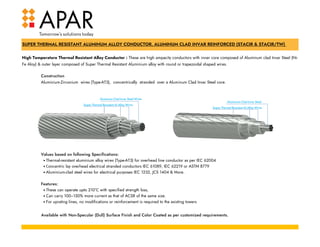

- 1. Construction Aluminium-Zirconium wires (Type-AT3), concentrically stranded over a Aluminum Clad Invar Steel core. Values based on following Specifications: • Thermal-resistant aluminium alloy wires (Type-AT3) for overhead line conductor as per IEC 62004 • Concentric lay overhead electrical stranded conductors IEC 61089, IEC 62219 or ASTM B779 • Aluminium-clad steel wires for electrical purposes IEC 1232, JCS 1404 & More. Features: • These can operate upto 210°C with specified strength loss, • Can carry 100~150% more current as that of ACSR of the same size. • For uprating lines, no modifications or reinforcement is required to the existing towers SUPER THERMAL RESISTANT ALUMINUM ALLOY CONDUCTOR, ALUMINUM CLAD INVAR REINFORCED (STACIR & STACIR/TW) High Temperature Thermal Resistant Alloy Conductor : These are high ampacity conductors with inner core composed of Aluminum clad Invar Steel (Ni- Fe Aloy) & outer layer composed of Super Thermal Resistant Aluminium alloy with round or trapezoidal shaped wires. Super Thermal Resistant Al.Alloy Wires Aluminum Clad Invar Steel Wires Super Thermal Resistant Al.Alloy Wires Aluminium Clad Invar Steel Available with Non-Specular (Dull) Surface Finish and Color Coated as per customized requirements.

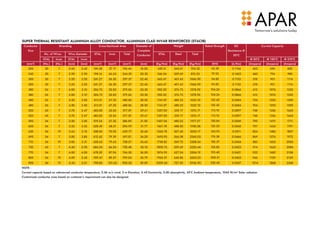

- 2. SUPER THERMAL RESISTANT ALUMINUM ALLOY CONDUCTOR, ALUMINUM CLAD INVAR REINFORCED (STACIR) STAL Invar STAL Invar @ 85°C @ 150°C @ 210°C (mm²) (No.) (No.) (mm) (mm) (mm²) (mm²) (mm²) (mm) (Kg/Km) (Kg/Km) (Kg/Km) (Ω/Km) (Ampere) (Ampere) (Ampere) 200 30 7 2.60 2.60 159.28 37.17 196.44 18.20 439.31 265.01 704.32 0.1746 403 690 850 240 30 7 2.90 2.90 198.16 46.24 244.39 20.30 546.54 329.69 876.23 0.1403 460 794 980 300 30 7 3.20 3.20 241.27 56.30 297.57 22.40 665.47 401.43 1066.90 0.1153 518 901 1114 300 30 7 3.20 3.20 241.27 56.30 297.57 22.40 665.47 401.43 1066.90 0.1153 518 901 1114 380 26 7 4.00 3.10 326.73 52.83 379.56 25.30 902.22 376.73 1278.95 0.0866 612 1076 1335 380 26 7 4.00 3.10 326.73 52.83 379.56 25.30 902.22 376.73 1278.95 0.0866 612 1076 1335 480 26 7 4.50 3.50 413.51 67.35 480.86 28.50 1141.87 480.23 1622.10 0.0684 704 1253 1559 480 26 7 4.50 3.50 413.51 67.35 480.86 28.50 1141.87 480.23 1622.10 0.0684 704 1253 1559 520 45 7 3.70 2.47 483.85 33.54 517.39 29.61 1337.00 239.17 1576.17 0.0597 748 1336 1665 520 45 7 3.70 2.47 483.85 33.54 517.39 29.61 1337.00 239.17 1576.17 0.0597 748 1336 1665 590 54 7 3.50 3.50 519.54 67.35 586.89 31.50 1437.04 480.23 1917.27 0.0549 790 1419 1771 600 54 7 3.53 3.53 528.49 68.51 596.99 31.77 1461.78 488.50 1950.28 0.0540 797 1434 1791 630 54 19 3.63 2.18 558.85 70.92 629.77 32.68 1545.78 507.40 2053.17 0.0511 824 1486 1857 690 54 7 3.80 3.80 612.42 79.39 691.81 34.20 1693.95 566.08 2260.03 0.0466 869 1576 1972 710 54 19 3.85 2.31 628.65 79.63 708.27 34.65 1738.82 569.72 2308.54 0.0454 883 1602 2006 730 45 7 4.40 2.90 684.24 46.24 730.48 35.10 1890.75 329.69 2220.44 0.0423 914 1663 2084 770 54 7 4.00 4.00 678.59 87.96 766.55 36.00 1876.95 627.24 2504.19 0.0421 922 1682 2108 800 54 19 4.09 2.45 709.47 89.57 799.04 36.79 1962.37 640.86 2603.23 0.0403 946 1729 2169 900 54 19 4.34 2.61 798.85 101.65 900.50 39.09 2209.60 727.30 2936.90 0.0357 1014 1868 2348 NOTE : Current capacity based on referenced conductor temperature, 0.56 m/s wind, 0 m Elevation, 0.45 Emmisivity, 0.80 absorptivity, 45°C Ambient temperature, 1045 W/m² Solar radiation Customized conductor sizes based on customer's requirement can also be designed. Conductor Size Stranding Cross-Sectional Area Diameter of Complete Conductor Weight DC Resistance @ 20°C Current Capacity Steel Total Rated Strength No. of Wires Wire diameter STAL Invar Total STAL 104.26 132.42 132.42 113.10 113.10 150.84 (KN) 65.38 79.92 94.82 94.82 104.26 205.51 230.40 152.20 163.93 176.38 182.37 155.82 193.40

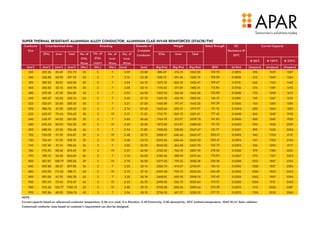

- 3. SUPER THERMAL RESISTANT ALUMINUM ALLOY CONDUCTOR, ALUMINUM CLAD INVAR REINFORCED (STACIR/TW) @ 85°C @ 150°C @ 210°C (mm²) (mm²) (mm²) (mm²) (No.) (No.) (No.) (mm) (mm) (Kg/Km) (Kg/Km) (Kg/Km) (Ω/Km) (Ampere) (Ampere) (Ampere) 320 322.26 52.49 374.75 20 2 7 3.09 22.88 888.49 374.31 1262.80 0.0876 596 1039 1287 340 336.85 54.90 391.75 20 2 7 3.16 23.38 928.73 391.46 1320.19 0.0838 612 1069 1324 390 389.25 50.81 440.06 20 2 7 3.04 24.72 1073.18 362.29 1435.47 0.0731 662 1163 1442 405 402.83 52.15 454.98 20 2 7 3.08 25.14 1110.62 371.89 1482.51 0.0706 676 1189 1475 480 479.69 47.20 526.89 35 3 7 2.93 26.98 1329.03 336.55 1665.58 0.0600 733 1298 1613 490 489.57 63.55 553.13 24 2 7 3.40 27.70 1349.78 453.18 1802.96 0.0581 759 1347 1676 525 523.67 26.85 550.53 30 3 7 2.21 27.50 1450.88 191.47 1642.35 0.0556 763 1354 1685 590 586.76 41.28 628.03 33 3 7 2.74 29.40 1625.66 294.31 1919.97 0.0494 820 1464 1825 625 625.07 79.63 704.69 38 3 19 2.31 31.32 1731.79 569.72 2301.51 0.0458 862 1549 1935 640 636.97 44.03 681.00 35 3 7 2.83 30.60 1764.78 313.97 2078.75 0.0455 860 1542 1925 680 676.24 85.95 762.20 39 3 19 2.40 32.58 1873.58 614.97 2488.55 0.0423 903 1630 2037 690 688.96 47.52 736.48 36 3 7 2.94 31.80 1908.82 338.85 2247.67 0.0421 899 1620 2024 725 725.09 91.78 816.87 39 3 19 2.48 33.72 2008.91 656.66 2665.57 0.0395 940 1703 2131 730 726.41 91.78 818.19 39 3 19 2.48 33.75 2012.56 656.66 2669.22 0.0394 941 1705 2134 740 737.40 51.14 788.54 36 3 7 3.05 32.92 2043.02 364.68 2407.70 0.0393 936 1692 2117 780 776.92 98.56 875.49 39 3 19 2.57 34.90 2152.52 705.18 2857.70 0.0368 979 1780 2231 790 789.13 54.55 843.69 36 3 7 3.15 34.05 2186.36 388.98 2575.34 0.0367 973 1767 2213 820 821.87 108.79 930.65 39 3 19 2.70 36.00 2277.05 778.33 3055.38 0.0348 1012 1847 2316 840 839.80 58.07 897.88 36 3 7 3.25 35.14 2326.74 414.07 2740.81 0.0345 1008 1837 2304 880 876.90 111.22 988.11 42 3 19 2.73 37.10 2429.50 795.72 3225.22 0.0326 1050 1923 2414 890 891.08 61.70 952.78 42 3 7 3.35 36.18 2468.81 439.95 2908.76 0.0325 1043 1907 2394 900 901.93 73.54 975.47 42 3 19 2.22 36.70 2498.85 526.19 3025.04 0.0320 1054 1931 2425 980 976.36 123.77 1100.13 42 3 19 2.88 39.12 2705.08 885.56 3590.64 0.0293 1115 2056 2587 990 987.86 68.90 1056.76 42 3 7 3.54 38.10 2736.95 491.27 3228.22 0.0293 1105 2035 2560 NOTE : Current capacity based on referenced conductor temperature, 0.56 m/s wind, 0 m Elevation, 0.45 Emmisivity, 0.80 absorptivity, 45°C Ambient temperature, 1045 W/m² Solar radiation Customized conductor sizes based on customer's requirement can also be designed. Current Capacity STAL Invar Total No. of STAL Wires No. of STAL Layers No. of Invar Wires Dia. of Invar Wires STAL Cross-Sectional Area Stranding Diameter of Complete Conductor Weight Invar Total DC Resistance @ 20°C Conductor Size Rated Strength (KN) 100.95 105.55 109.47 112.86 123.00 136.19 185.14 246.40 177.43 141.60 191.75 151.77 107.39 131.16 195.42 213.21 274.28 217.12 205.21 205.41 162.72 218.33 173.95 235.56