4 day. Abrasion + Practice oil and gas.pptx

- 1. Abrasion Novomet Application Engineers School

- 2. 2 Sand production reasons ŌĆó Removal of separate particles or their conglomerates by flow ŌĆó Structural fracture and structure change of producing formation ŌĆó Development of formation fracture processes ŌĆó Reservoir deformation and structure in bottom-hole area

- 3. 3 Factors influencing formation fracture ŌĆó High fluid rates; ŌĆó Low bottom-hole pressure and high pressure drawdown; ŌĆó Size, rounded shape and inhomogeneity of sand; ŌĆó Rock friction factor, formation consolidation; ŌĆó Compressibility and natural permeability of formation; ŌĆó Well completion type;

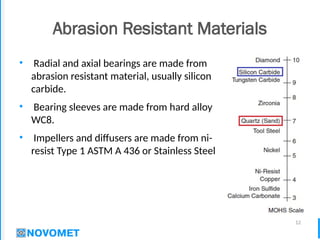

- 4. 4 Characteristics of Abrasive Materials The hardness of the abrasive particles as compared to that of the attacked metal has a direct effect on the damage made. Since no abrasive will cut anything harder than itself, metal surfaces in ESP pumps used for abrasive service must be harder than the abrasive contained in the fluid. As seen, sand or quartz (SiO2) is harder than tool steel or nickel but cannot damage the much harder materials like tungsten carbide or zirconia. The materials of other solids usually present in fluid (iron sulfate, calcium carbonate) are much softer than sand; it is the reason why sand is considered the key abrasive substance in oil wells.

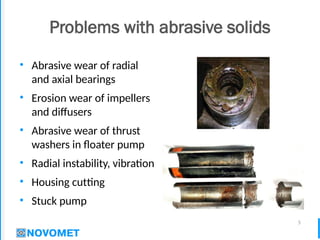

- 5. 5 Problems with abrasive solids ŌĆó Abrasive wear of radial and axial bearings ŌĆó Erosion wear of impellers and diffusers ŌĆó Abrasive wear of thrust washers in floater pump ŌĆó Radial instability, vibration ŌĆó Housing cutting ŌĆó Stuck pump

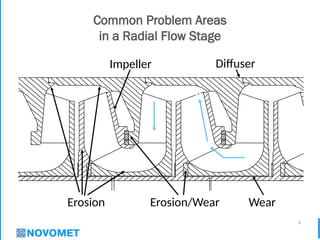

- 6. 6 Common Problem Areas in a Radial Flow Stage Impeller Diffuser Flowpath Erosion Wear Erosion/Wear

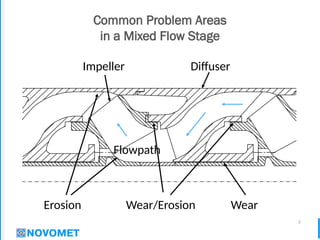

- 7. 7 Common Problem Areas in a Mixed Flow Stage Impeller Diffuser Erosion Wear Wear/Erosion Flowpath

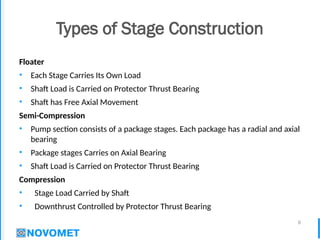

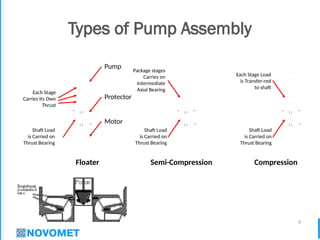

- 8. 8 Types of Stage Construction Floater ŌĆó Each Stage Carries Its Own Load ŌĆó Shaft Load is Carried on Protector Thrust Bearing ŌĆó Shaft has Free Axial Movement Semi-Compression ŌĆó Pump section consists of a package stages. Each package has a radial and axial bearing ŌĆó Package stages Carries on Axial Bearing ŌĆó Shaft Load is Carried on Protector Thrust Bearing Compression ŌĆó Stage Load Carried by Shaft ŌĆó Downthrust Controlled by Protector Thrust Bearing

- 9. 9 Types of Pump Assembly Floater Compression Semi-Compression Each Stage Carries Its Own Thrust Motor Protector Pump Shaft Load is Carried on Thrust Bearing Shaft Load is Carried on Thrust Bearing Shaft Load is Carried on Thrust Bearing Package stages Carries on Intermediate Axial Bearing Each Stage Load is Transfer-red to shaft

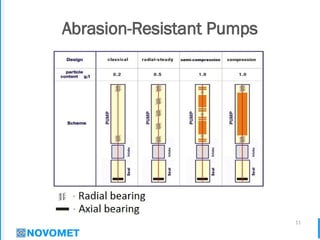

- 12. 12 Abrasion Resistant Materials ŌĆó Radial and axial bearings are made from abrasion resistant material, usually silicon carbide. ŌĆó Bearing sleeves are made from hard alloy WC8. ŌĆó Impellers and diffusers are made from ni- resist Type 1 ASTM A 436 or Stainless Steel

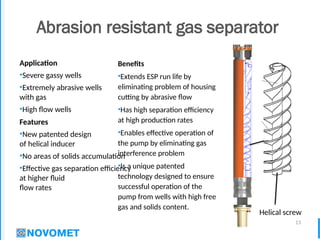

- 13. 13 Abrasion resistant gas separator Benefits ŌĆóExtends ESP run life by eliminating problem of housing cutting by abrasive flow ŌĆóHas high separation efficiency at high production rates ŌĆóEnables effective operation of the pump by eliminating gas interference problem ŌĆóIs a unique patented technology designed to ensure successful operation of the pump from wells with high free gas and solids content. Application ŌĆóSevere gassy wells ŌĆóExtremely abrasive wells with gas ŌĆóHigh flow wells Features ŌĆóNew patented design of helical inducer ŌĆóNo areas of solids accumulation ŌĆóEffective gas separation efficiency at higher fluid flow rates Helical screw

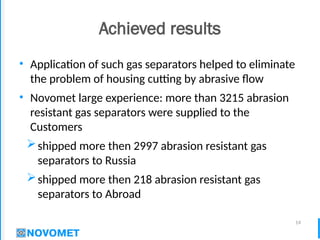

- 14. 14 Achieved results ŌĆó Application of such gas separators helped to eliminate the problem of housing cutting by abrasive flow ŌĆó Novomet large experience: more than 3215 abrasion resistant gas separators were supplied to the Customers ’āśshipped more then 2997 abrasion resistant gas separators to Russia ’āśshipped more then 218 abrasion resistant gas separators to Abroad

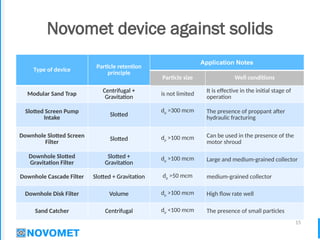

- 15. 15 Novomet device against solids Type of device Particle retention principle Application Notes Particle size Well conditions Modular Sand Trap Centrifugal + Gravitation is not limited It is effective in the initial stage of operation Slotted Screen Pump Intake Slotted dp >300 mcm The presence of proppant after hydraulic fracturing Downhole Slotted Screen Filter Slotted dp >100 mcm Can be used in the presence of the motor shroud Downhole Slotted Gravitation Filter Slotted + Gravitation dp >100 mcm Large and medium-grained collector Downhole Cascade Filter Slotted + Gravitation dp >50 mcm medium-grained collector Downhole Disk Filter Volume dp >100 mcm High flow rate well Sand Catcher Centrifugal dp <100 mcm The presence of small particles

- 16. 16 Modular Sand Trap (MST) Set up place ŌĆó as a additional section between intake (gas separator) and lower pump section. Features ŌĆósolids due to gravitational force are settle in the pocket Benefits ŌĆórunlife increase; ŌĆórun and pull with ESP; ŌĆórepair ability; ŌĆóapplication with ESPs of different manufacturers Parameters series 362, 406 series Flow rate 750 and 1500 bpd Flow rate Length 4-6 m Length

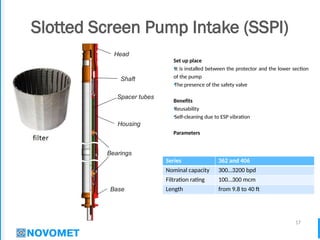

- 17. 17 Slotted Screen Pump Intake (SSPI) Set up place ŌĆóIt is installed between the protector and the lower section of the pump ŌĆóThe presence of the safety valve Benefits ŌĆóReusability ŌĆóSelf-cleaning due to ESP vibration Parameters Series 362 and 406 Nominal capacity 300ŌĆ”3200 bpd Filtration rating 100ŌĆ”300 mcm Length from 9.8 to 40 ft Bearings Base Head Shaft Housing Spacer tubes

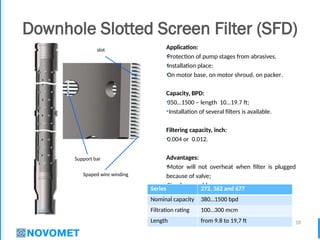

- 18. 18 Downhole Slotted Screen Filter (SFD) Application: ŌĆóProtection of pump stages from abrasives. ŌĆóInstallation place: ŌĆóOn motor base, on motor shroud, on packer. Capacity, BPD: ŌĆó350ŌĆ”1500 ŌĆō length 10ŌĆ”19.7 ft; ŌĆóInstallation of several filters is available. Filtering capacity, inch: ŌĆó0.004 or 0.012. Advantages: ŌĆóMotor will not overheat when filter is plugged because of valve; ŌĆóSimple assembly; ŌĆóHigh strength of filter element. Spaped wire winding Support bar slot Series 272, 362 and 677 Nominal capacity 380ŌĆ”1500 bpd Filtration rating 100ŌĆ”300 mcm Length from 9.8 to 19,7 ft

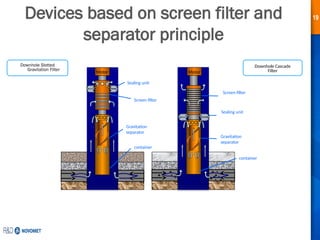

- 19. 19 Devices based on screen filter and separator principle Screen filter Gravitation separator Sealing unit Motor Screen filter Gravitation separator container Sealing unit Motor Downhole Slotted Gravitation Filter container Downhole Cascade Filter

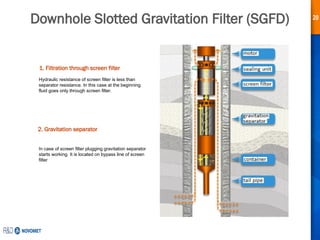

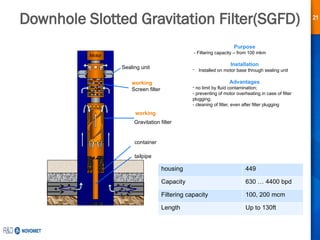

- 20. 20 Downhole Slotted Gravitation Filter (SGFD) 1. Filtration through screen filter 2. Gravitation separator Hydraulic resistance of screen filter is less than separator resistance. In this case at the beginning fluid goes only through screen filter. In case of screen filter plugging gravitation separator starts working. It is located on bypass line of screen filter

- 21. 21 Downhole Slotted Gravitation Filter(SGFD) Motor Screen filter Gravitation filter container working working Sealing unit Purpose - Filtering capacity ŌĆō from 100 mkm Installation - Installed on motor base through sealing unit Advantages - no limit by fluid contamination; - preventing of motor overheating in case of filter plugging; - cleaning of filter, even after filter plugging tailpipe housing 449 Capacity 630 ŌĆ” 4400 bpd Filtering capacity 100, 200 mcm Length Up to 130ft

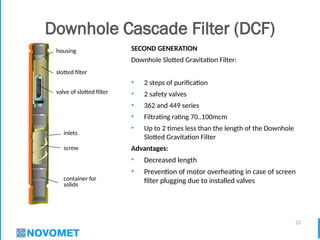

- 22. 22 Downhole Cascade Filter (DCF) SECOND GENERATION Downhole Slotted Gravitation Filter: ŌĆó 2 steps of purification ŌĆó 2 safety valves ŌĆó 362 and 449 series ŌĆó Filtrating rating 70..100mcm ŌĆó Up to 2 times less than the length of the Downhole Slotted Gravitation Filter Advantages: ŌĆó Decreased length ŌĆó Prevention of motor overheating in case of screen filter plugging due to installed valves container for solids screw inlets valve of slotted filter slotted filter housing

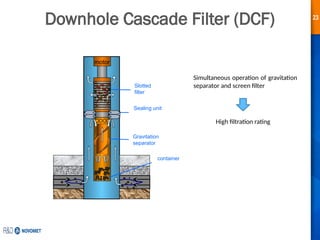

- 23. 23 Downhole Cascade Filter (DCF) Slotted filter Gravitation separator container Sealing unit motor Simultaneous operation of gravitation separator and screen filter High filtration rating

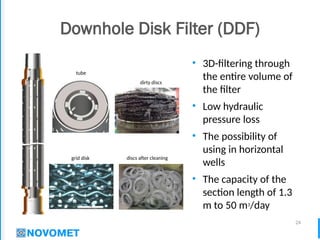

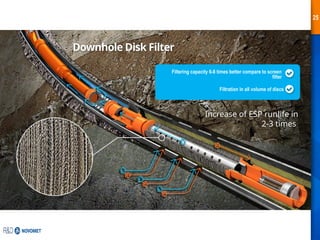

- 24. 24 Downhole Disk Filter (DDF) ŌĆó 3D-filtering through the entire volume of the filter ŌĆó Low hydraulic pressure loss ŌĆó The possibility of using in horizontal wells ŌĆó The capacity of the section length of 1.3 m to 50 m3 /day tube grid disk dirty discs discs after cleaning

- 25. 25 Downhole Disk Filter Increase of ESP runlife in 2-3 times Filtering capacity 6-8 times better compare to screen filter Filtration in all volume of discs

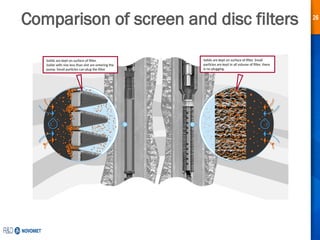

- 26. 26 Comparison of screen and disc filters Solids are kept on surface of filter. Solids with size less than slot are entering the pump. Small particles can plug the filter Solids are kept on surface of filter. Small particles are kept in all volume of filter, there is no plugging.

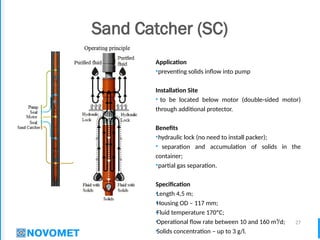

- 27. 27 Sand Catcher (SC) Application ŌĆópreventing solids inflow into pump Installation Site ŌĆó to be located below motor (double-sided motor) through additional protector. Benefits ŌĆóhydraulic lock (no need to install packer); ŌĆó separation and accumulation of solids in the container; ŌĆópartial gas separation. Specification ŌĆóLength 4,5 m; ŌĆóHousing OD ŌĆō 117 mm; ŌĆóFluid temperature 170┬║ąĪ; ŌĆóOperational flow rate between 10 and 160 m┬│/d; ŌĆóSolids concentration ŌĆō up to 3 g/l.

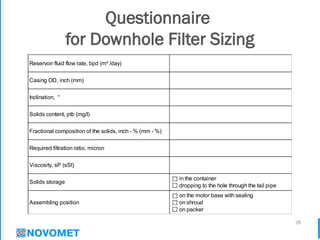

- 28. 28 Questionnaire for Downhole Filter Sizing Viscosity, sP (sSt) in the container dropping to the hole through the tail pipe Required filtration ratio, micron Solids storage Reservoir fluid flow rate, bpd (m┬│ /day) Casing OD, inch (mm) Fractional composition of the solids, inch - % (mm - %) Inclination, ┬░ Solids content, ptb (mg/l) on the motor base with sealing on shroud on packer Assembling position

- 29. 29 Practice

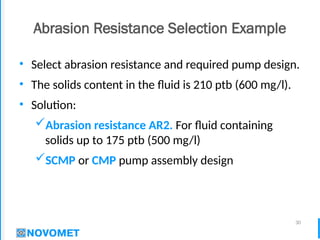

- 30. 30 Abrasion Resistance Selection Example ŌĆó Select abrasion resistance and required pump design. ŌĆó The solids content in the fluid is 210 ptb (600 mg/l). ŌĆó Solution: ’ā╝Abrasion resistance AR2. For fluid containing solids up to 175 ptb (500 mg/l) ’ā╝SCMP or CMP pump assembly design

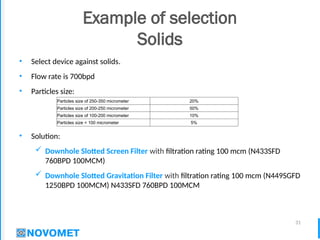

- 31. 31 Example of selection Solids ŌĆó Select device against solids. ŌĆó Flow rate is 700bpd ŌĆó Particles size: ŌĆó Solution: ’ā╝ Downhole Slotted Screen Filter with filtration rating 100 mcm (N433SFD 760BPD 100MCM) ’ā╝ Downhole Slotted Gravitation Filter with filtration rating 100 mcm (N449SGFD 1250BPD 100MąĪM) N433SFD 760BPD 100MCM Particles size of 250-350 micrometer 20% Particles size of 200-250 micrometer 50% Particles size of 100-200 micrometer 10% Particles size < 100 micrometer 5%

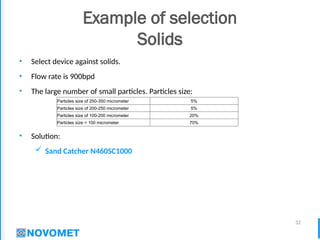

- 32. 32 Example of selection Solids ŌĆó Select device against solids. ŌĆó Flow rate is 900bpd ŌĆó The large number of small particles. Particles size: ŌĆó Solution: ’ā╝ Sand Catcher N460SC1000 Particles size of 250-350 micrometer 5% Particles size of 200-250 micrometer 5% Particles size of 100-200 micrometer 20% Particles size < 100 micrometer 70%

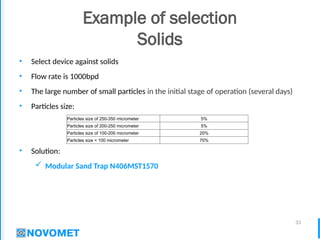

- 33. 33 Example of selection Solids ŌĆó Select device against solids ŌĆó Flow rate is 1000bpd ŌĆó The large number of small particles in the initial stage of operation (several days) ŌĆó Particles size: ŌĆó Solution: ’ā╝ Modular Sand Trap N406MST1570 Particles size of 250-350 micrometer 5% Particles size of 200-250 micrometer 5% Particles size of 100-200 micrometer 20% Particles size < 100 micrometer 70%

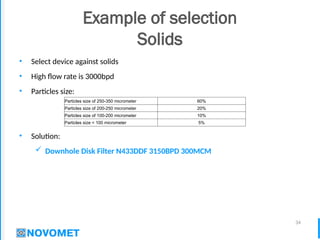

- 34. 34 Example of selection Solids ŌĆó Select device against solids ŌĆó High flow rate is 3000bpd ŌĆó Particles size: ŌĆó Solution: ’ā╝ Downhole Disk Filter N433DDF 3150BPD 300MCM Particles size of 250-350 micrometer 60% Particles size of 200-250 micrometer 20% Particles size of 100-200 micrometer 10% Particles size < 100 micrometer 5%

Editor's Notes

- #21: ąÉąĮąĖą╝ą░čåąĖčÅ ą┐ąŠ čēąĄą╗čćą║čā ą╝čŗčłąĖ