5 s @ asrotex

- 1. Doing things Simpler, Efficient and Competitive Through a Habitual change of Continuous Improvement ,Cleaner and Safer working Environment. 5S Philosophy

- 2. ï§ SortSort ï§ Set in orderSet in order ï§ ShineShineetsu ï§ StandardizeStandardize ï§ SustainSustain 5S5S 5S Stand For?

- 3. The first SS focuses on eliminating unnecessary items from the workplace. Seiri SortSort Removing Unwanted

- 4. Segregate What Is Needed Needed Later Not Needed Discard What Is Not Needed Segregate Needed Items By Frequency of Use Seiri SortSort

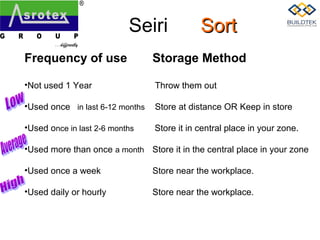

- 5. Seiri SortSort Frequency of use Storage Method âĒNot used 1 Year Throw them out âĒUsed once in last 6-12 months Store at distance OR Keep in store âĒUsed once in last 2-6 months Store it in central place in your zone. âĒUsed more than once a month Store it in the central place in your zone âĒUsed once a week Store near the workplace. âĒUsed daily or hourly Store near the workplace.

- 6. 3 Things You Should Ask âĒ What do I need to do my job? âĒ Where should I locate this item? âĒ How many do I need? The second SS focuses on efficient and effective storage methods. You must ask yourself these questions: Unwanted has been removed Now how to store effectively Seiton Set in order

- 7. ï§ Painting floors ï§ Outlining work areas and locations, Arrows Show Direction. Limit lines- Maxm, Minm ï§ Modular shelving and cabinets, Outlines ï§ Color Coding, Signs Seiton Set in order A Place for Every Thing A Place for Every Thing And And Every thing in Its Place Every thing in Its Place Lines Divider lines Outlines Limit lines (height, minimum/maximum) Arrows show direction

- 8. Shadow Boards Tools Boards Labels Color coding Item location / Sign Boards Office Storage File Cabinets Working Table Shelves, etc. Seiton Set in order

- 9. Unwanted has been removed ; Stored effectively Now Clean it Seiso ShineShine Clean everything, inside and out Inspect through cleaning Prevent dirt, and contamination from reoccurring Results in .Fewer breakdowns âĒ Greater safety âĒ Product quality âĒ More satisfying work environment

- 10. Seiso ShineShine Cleaning Check List âĒ Ceilings âĒ Aisles âĒ Workstations âĒ Corners, under equipment âĒ Loading docks âĒ Walls âĒ Doors âĒ Pillars, posts âĒ Floors âĒ Machines âĒ Conveyance equipment âĒ Plumbing, sinks âĒ Cabinets, shelves, racks âĒ Carts, Racks âĒ Drawers, storage bins âĒ Fixtures, power boxes

- 11. Once the first three of the 5Sâs have been implemented âĒStandardize best practice in work area. âĒDocumentation of such standards. Unwanted has been removed ; Stored effectively ;All are Clean Now How to Adopt best Practices Seiketsu StandardizeStandardize âĒ Sort â Amount of inventory â Tools that belong in the area â How often to remove scrap âĒ Straighten â Location of aisle ways â Location of tools, equipment âĒ Shine â Cleaning schedule â Maintenance tasks â Checklist of what to look for as cleaning is performed

- 12. Sustain SitsukeSitsuke Unwanted has been removed ; Stored effectively ;All are Clean; Adopted best Practices Now how to maintain what we have achieved Determine the methods your team will use to maintain adherence to the standards âĒ 5-S concept training âĒ 5-S communication board âĒ Before and after photos âĒ One point lesson âĒ Visual standards and procedures âĒ Daily 5-minute 5-S activities âĒ Monthly 5-S Audit & Recognition

- 13. Target Area Vision Safety Current Condition Desired Conditions

- 14. Target Area Vision Product Quality Current Condition Desired Conditions

- 15. Target Area Vision Equipment Maintenance Current Condition Desired Conditions

- 16. Target Area Vision Work Efficiency Current Condition Desired Conditions

- 17. Target Area Vision Inventory Levels Current Condition Desired Conditions

- 18. Target Area Vision Information Flow Current Condition Desired Conditions

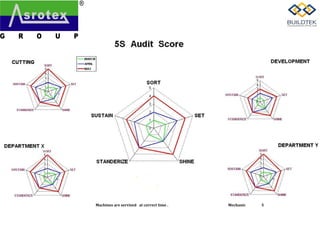

- 20.   Responsible Mark s 1 NOT REQUIRED ITEMS IN THE LINE        Tops and insides of all cupboards, shelves, tables, drawers, etc. free of unwanted/unused items Supervisor 10     2 ITEMS NOT IN CORRECT PLACE    All alleyways area clearly marked and respected PM 5  All floors/walkways clear Supervisor 5  All  tools / files etc. are arranged in a clear order with a file index maintained: Supervisor 5  Garmment at In line - End line -Feeding  areas need on correct placees. Should not be messy around Supervisor/ QC 5  All electrical sockets and wiring are correctly maintained and in working order Mechanic 5    3 LINE NOT FREE FROM DIRT    Floors, are maintained at a high level of cleanliness/dust free: Supervisor 5  Machines, equipment, tools, furniture maintained at a high level of cleanliness Mechanic 5  Machines are servised   at correct time . Mechanic 5

Editor's Notes

- #3: Listed above is the implementation plan for a 5S program. Each step is explained on the upcoming slides.