5s

- 1. Lack of 5 S practices in Colleges Canteen Presentedby Saloni Nagar,Saloni Singhal and Komal Grewal.

- 2. OBJECTIVES ’āÆ First to introduce the 5 s process EPIC Owner members and non members ’āÆ To illustrate the importance of the 5 s process in the work area and everyday living ’āÆ To equip EPIC owner members and the non members with the knowledge of the 5 s process that they can apply in their present future work.

- 11. SEIRI ’āÆ Seiri is sorting the contents of the workplace and removing unnecessary items. This is an action to identify and eliminate all unnecessary items from different places in the workplace. This refers to the practice of sorting all the materials in the canteen and keeping only essential items. Everything else is stored or discarded. This leads to lesser hazards and less clutter to affect the productive work. Seiri helps in maintaining a clean place and also help in increasing the productivity.

- 12. TAKING EXAMPLE OF JAGRAT UNIVERSITY CANTEEN ’āÆ The basement of college is used for various purposes like ,it has the canteen, it is utilized as the place for dining purpose. The outer area of the basement has hand washing basins ,placed for drinking water and placed for disposing the used plates.

- 13. The glasses are not very well maintained in the rack making it difficult for the students to understand the difference between the used and the unused glasses

- 14. The plates are also in messed way ..!!they should be in a more orderly manner ..!!

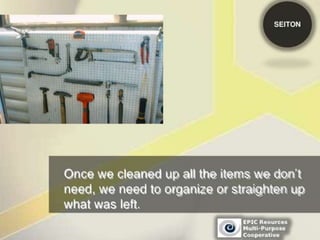

- 15. SEITON-SET IN ORDER ’āś ŌĆ£One place for everything and everything in its placeŌĆØ becomes the way of thinking for every member when the second stage of 5S implemented. The main aim for this stage is that it helps the people to know the correct place to find the things for which he or she is searching around. ’āś This phase helps in removing the muda i.e. waste which does arise in day to day lifeŌĆ”!!! ’üČ Motion waste ’üČ Searching waste ’üČ The waste of human energy ’üČ The waste of unsafe conditions

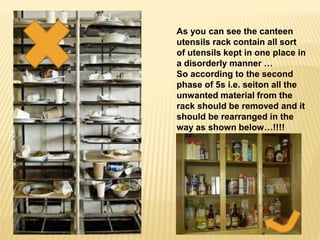

- 16. As you can see the canteen utensils rack contain all sort of utensils kept in one place in a disorderly manner ŌĆ” So according to the second phase of 5s i.e. seiton all the unwanted material from the rack should be removed and it should be rearranged in the way as shown belowŌĆ”!!!!

- 17. SEISO-SHINE ’āÆ We know that cleanliness is next to GOD, this step indicates to keep the place i.e. the institute clean and neat. Regular cleaning in a proper way helps to identify and eliminate the wastes. During cleaning the cleaning of floors, toilets, canteen, store places etc. ’āÆ Main importance: ’üČ Turn workplace into clean, bright place where we will enjoy working. ’üČ Keep everything in top condition so that when someone needs to use something it is ready to be used. ’üČ Cleaning should become a daily habit like bathing.

- 18. The canteen kitchen is very messy and untidy as it is not regularly cleaned, is very unhygienic and can cause many diseases. In order to avoid endemic environment in the environment seiso the third technique of 5S should be implemented..!!

- 19. SEIKETSU-STANDARDIZE ’āÆ Seiketsu involves in creating visual controls and guidelines for keeping the institute in an organized and orderly place and also keep it clean. In this step very high standard of housekeeping is been followed. Seiketsu helps to return back and work in a standard order or way. ’āÆ The problem that can be avoided by implementing seiketsu are: ’üČ Conditions go back to their old undesirable levels even after implementing 5S throughout the college. ’üČ At the end of the day piles of waste items are left out. ’üČ Any storage place become disorganized and must be put back in order at the end of the day.

- 21. SHITSUKE-SUSTAIN ’āÆ The final stage is that of being discipline to retain the initial use of s it is needed to sustain and be self disciplined. The way in which management achieves this establishment of ongoing commitment within the work force depends, on the culture and disciplined they follow from starting. This step increases the consciousness of staff and decreases the number of waste goods and processes. problems that can be avoided by implementing this phase of 5S: ’üČ Unneeded items begin piling up as soon as sorting is completed. ’üČ No matter how well set in order is planned and implemented, tools and jigs do not get returned to their designated places after use. ’üČ Little or nothing is done to clean the equipments even when it gets ready. ’üČ Dark, dirty disorganized institute will affect the education system in the institute.

- 22. FOLLOWINGS CAN BE HARNESSED FROM THE 5S 1. NEAT & CLEAN WORKPLACE 2. SMOOTH WORKING 3. NO OBSTRUCTION 4. SAFETY INCREASES 5. PRODUCTIVITY IMPROVES

- 23. CONT. 6. QUALITY IMPROVES 7. WASTAGE DECREASE 8. MACHINE MAINTENANCE 9. VISUAL CONTROL SYSTEM 10. EMPLOYEES MOTIVATED 11. WORKSTATIONS BECOME SPACIOUS

- 24. Thank you