5S AWARENESS.docx

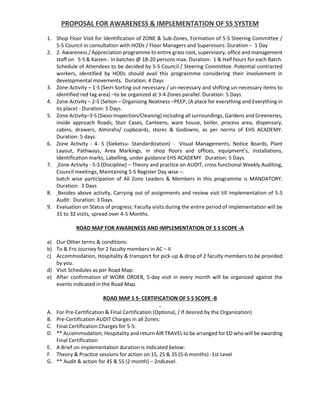

- 1. PROPOSAL FOR AWARENESS & IMPLEMENTATION OF 5S SYSTEM 1. Shop Floor Visit for Identification of ZONE & Sub-Zones, Formation of 5-S Steering Committee / 5-S Council in consultation with HODs / Floor Managers and Supervisors: Duration â 1 Day 2. 2. Awareness / Appreciation programme to entire grass root, supervisory, office and management staff on 5-S & Kaizen.: In batches @ 18-20 persons max. Duration: 1 & Half hours for each Batch. Schedule of Attendees to be decided by 5-S Council / Steering Committee. Potential contracted workers, identified by HODs should avail this prograsmme considering their involvement in developmental movements. Duration: 4 Days 3. Zone Activity â 1-S (Seiri-Sorting out necessary / un-necessary and shifting un-necessary items to identified red tag area) âto be organized at 3-4 Zones parallel. Duration: 5 Days 4. Zone Activity â 2-S (Seiton â Organizing Neatness âPEEP, (A place for everything and Everything in its place) - Duration: 5 Days. 5. Zone Activityâ3-S (Sieso-Inspection/Cleaning) including all surroundings, Gardens and Greeneries, inside approach Roads, Stair Cases, Canteens, ware house, boiler, process area, dispensary, cabins, drawers, Almirahs/ cupboards, stores & Godowns, as per norms of EHS ACADEMY. Duration: 5 days. 6. Zone Activity - 4- S (Sieketsu- Standardization) - Visual Managements, Notice Boards, Plant Layout, Pathways, Area Markings, in shop floors and offices, equipmentâs, Installations, Identification marks, Labelling, under guidance EHS ACADEMY Duration: 5 Days. 7. Zone Activity - 5-S (Discipline) â Theory and practice on AUDIT, cross functional Weekly Auditing, Council meetings, Maintaining 5-S Register Day wise â. batch wise participation of All Zone Leaders & Members in this programme is MANDATORY. Duration: 3 Days 8. Besides above activity, Carrying out of assignments and review visit till implementation of 5-S Audit: Duration: 3 Days. 9. Evaluation on Status of progress: Faculty visits during the entire period of implementation will be 31 to 32 visits, spread over 4-5 Months. ROAD MAP FOR AWARENESS AND IMPLEMENTATION OF 5 S SCOPE -A a) Our Other terms & conditions: b) To & Fro Journey for 2 faculty members in AC â II c) Accommodation, Hospitality & transport for pick-up & drop of 2 faculty members to be provided by you. d) Visit Schedules as per Road Map: e) After confirmation of WORK ORDER, 5-day visit in every month will be organized against the events indicated in the Road Map. ROAD MAP 5 S- CERTIFICATION OF 5 S SCOPE -B . A. For Pre-Certification & Final Certification (Optional, / If desired by the Organization) B. Pre-Certification AUDIT Charges in all Zones: C. Final Certification Charges for 5-S: D. ** Accommodation, Hospitality and return AIR TRAVEL to be arranged for ED who will be awarding Final Certification E. A Brief on implementation duration is indicated below: F. Theory & Practice sessions for action on 1S, 2S & 3S (5-6 months) -1st Level G. ** Audit & action for 4S & 5S (2 month) â 2ndLevel.