5S Management System

- 1. Prepared By Sajedur Rahman Head of IE Flaxen Dress Maker Ltd

- 2. 5S is a basic, fundamental, systematic approach for productivity, quality and safety improvement in all types of business

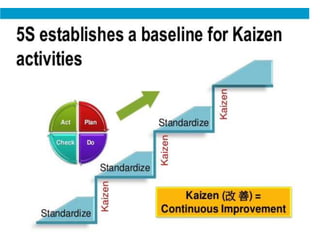

- 3. What is 5S? a 5s (five s) program is usually a part of, and the key component of establishing a visual workplace and are both a part of kaizen - a system of continual improvement - which is a component of lean manufacturing.

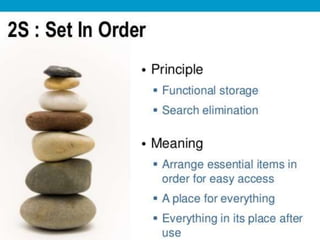

- 4. The 5S program focus on having visual order organization cleanliness standardization

- 19. Thank you all We Hope We Can successfully applied 5s System In Our Garments