5s system - greendot management solution

- 1. 5 S By: Yogendra Paida

- 2. •High efficiency •Organized work place •Highest quality •Safety •Housekeeping etc………………… And ultimately protect its investment What would any organisation like

- 3. What is 5S It is a system which creates a workplace that has •Minimized waste •More productive activities •Reduced chance of error •Reduced rework •High safety etc… Ultimately reducing cost and increasing productivity

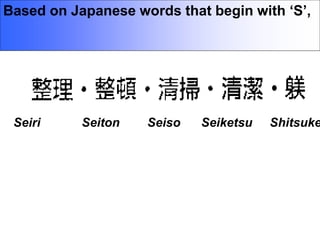

- 4. Seiri Seiton Seiso Seiketsu Shitsuke Based on Japanese words that begin with ‘S’,

- 5. The first ‘S’ Sort – (Seiri) Focuses on eliminating unnecessary items •Visual methods used to identify unneeded items like red tagging •These are moved to a central holding area and then discarded •Occasionally used items are moved to a more organized storage location outside of the work area Free’s up valuable floor space

- 6. Focuses on efficient and effective storage methods. • What is needed to do the job • Where should these be kept • How many items needed Strategies for effective Set In Order are: • Systematic arrangement • painting floors, • outlining work areas • cabinets for needed items "A place for everything and everything in its place." Second ‘S’ Set In Order (Seiton)

- 7. Focusses on clean work area • Daily cleaning is necessary • People will slowly take pride in a clean work area • Shine step helps create ownership It reduces equipment failure and loss of production. Third ‘S’ Shine (Seiso)

- 8. Focusses on standardizing best practice • everybody participates in development of standards. • valuable but often overlooked source of information regarding work. Improves productivity and efficiency Fourth ‘S’ Standardize: (Seiketsu)

- 9. Difficult, S focusses on Self-discipline • People resist change • The tendency is to return to comfort zone of the "old way" of doing things. Sustain focuses on defining a new status quo and standard of work place organization. Fifth ‘S’ (To keep first 4 S alive ) Sustain: (Shitsuke)

- 10.  Reduces Cost  Increases productivity  Minimized waste  Reduces the chance of error,  Reduced rework /defects-Better quality  Reduces equipment downtime  Safety  Improve efficiency  Organized work place  Reduced lead time Advantages

- 11. ANYWHERE Where can 5S be applied

- 12. Pens can be kept in a proper place, Where can 5S be applied

- 13. Books can be arranged properly Where can 5S be applied

- 14. Do not allow dustbin to overflow with regular cleaning Where can 5S be applied

- 15. THANK YOU Yogendra Paida Officer (HR&A)