5S-TPM

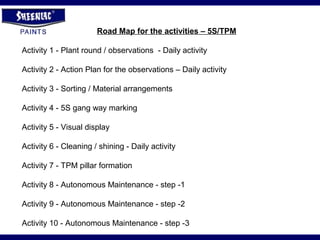

- 1. Road Map for the activities â 5S/TPM Activity 1 - Plant round / observations - Daily activity Activity 2 - Action Plan for the observations â Daily activity Activity 3 - Sorting / Material arrangements Activity 4 - 5S gang way marking Activity 5 - Visual display Activity 6 - Cleaning / shining - Daily activity Activity 7 - TPM pillar formation Activity 8 - Autonomous Maintenance - step -1 Activity 9 - Autonomous Maintenance - step -2 Activity 10 - Autonomous Maintenance - step -3

- 2. 5S Activity â BEFORE AND AFTER PICS

- 3. 5S Activity â BEFORE AND AFTER PICS

- 4. 5S Activity â BEFORE AND AFTER PICS

- 5. 5S Activity â BEFORE AND AFTER PICS

- 6. 5S Activity â BEFORE AND AFTER PICS

- 7. 5S Activity â BEFORE AND AFTER PICS

- 8. 5S Activity â BEFORE AND AFTER PICS

- 9. View of FG floor after 5S arrangement

- 10. ENGINEERING STORES AFTER 5S Activity

- 11. OFFICE AFTER 5S RE-ARRANGEMENT ACTIVITY

- 12. 1S & 2S benefits Removal of unwanted Items Identified the locked Cash by 1S & 2S Activity alone.

- 13. Unidentified and unused Materials details Unidentified / unused materials stored in the barrels are tested and Identified for usage. Total no. of Barrels â 551 = 75T / approx. value â Rs. 50 lakh Consumed in the month of Julâ14 â 170 barrels = 23T / Value â Rs. 16.78 lakh Stock for consumption Sepâ14 to Novâ14 â 168 barrels = 24T Other plant transfer â 14 barrels = 2.4T R&D test & confirmation â 31 barrels = 5.3T Not usable â 159 barrels = 24T FG/ SFG /D3 not usable & Packing materials not usable identified and separated from the usable materials.