Ace 402 lec 5 effective

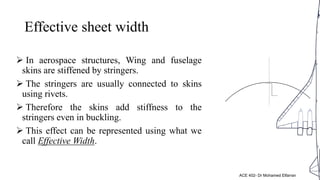

- 2. Effective sheet width ï In aerospace structures, Wing and fuselage skins are stiffened by stringers. ï The stringers are usually connected to skins using rivets. ï Therefore the skins add stiffness to the stringers even in buckling. ï This effect can be represented using what we call Effective Width. ACE 402- Dr Mohamed Elfarran

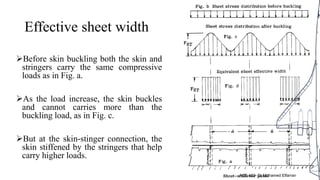

- 3. Effective sheet width ïBefore skin buckling both the skin and stringers carry the same compressive loads as in Fig. a. ïAs the load increase, the skin buckles and cannot carries more than the buckling load, as in Fig. c. ïBut at the skin-stinger connection, the skin stiffened by the stringers that help carry higher loads. ACE 402- Dr Mohamed Elfarran

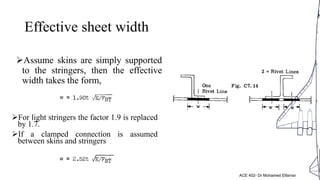

- 4. Effective sheet width ïAssume skins are simply supported to the stringers, then the effective width takes the form, ïFor light stringers the factor 1.9 is replaced by 1.7. ïIf a clamped connection is assumed between skins and stringers ACE 402- Dr Mohamed Elfarran

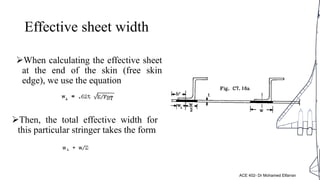

- 5. Effective sheet width ïWhen calculating the effective sheet at the end of the skin (free skin edge), we use the equation ïThen, the total effective width for this particular stringer takes the form ACE 402- Dr Mohamed Elfarran

- 6. Effective sheet width ïIf the stringers and skins have different material properties. We multiply the effective width equation by a correction factor . Notice that the symbol F used by Bruhn refers to stress which we usually refers to it by the symbol sigma ACE 402- Dr Mohamed Elfarran

- 7. Inter-Rivet Buckling ACE 402- Dr Mohamed Elfarran

- 8. Inter-Rivet Buckling âĒ If the distance between the skin rivets are too long, this can leads to inter-rivet buckling. âĒ Therefore, the rivet spacing is designed such that to prevent the inter- rivet buckling. âĒ To do so, we assume the sheets between rivets act as a column with restrained ends. ACE 402- Dr Mohamed Elfarran

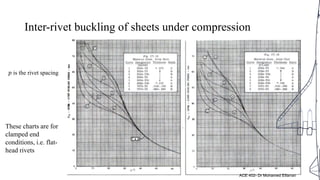

- 9. Inter-rivet buckling of sheets under compression is the rivet spacing These charts are for clamped end conditions, i.e. flat- head rivets ACE 402- Dr Mohamed Elfarran

- 10. Inter-rivet buckling of sheets under compression For other end conditions we use equivalent rivet spacing = 4 where C: rivets fixity coefficient P: rivet spacing And get Fir form figure C7.14 The rivets fixity coefficient For flat head 4 For spot welds 3.5 Brazier 3 counter-sunk 1 ACE 402- Dr Mohamed Elfarran

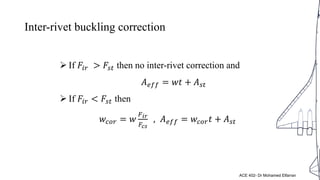

- 11. Inter-rivet buckling correction ï If > then no inter-rivet correction and = + ï If < then = , = + ACE 402- Dr Mohamed Elfarran