ADVIA Concept & Principles

Download as PPTX, PDF7 likes11,533 views

The document describes the ADVIA2120i hematology analyzer. It discusses the components, principles of operation, and maintenance of the analyzer. The key components are the analyzer unit, which contains the sampling and analysis mechanisms, and the personal computer. Samples are aspirated automatically or manually and analyzed using techniques like hydrodynamic focusing to provide a complete blood count, differential count, and reticulocyte results. Daily maintenance includes running control samples and performing a system wash cycle.

1 of 38

Downloaded 203 times

Recommended

Automation in hematology

Automation in hematologyDr Siddartha

╠²

Automation In Haematology.

Dept Of Lab Medicine

Basavatarakam Indo American Hospital And Research Institute

Automation in haematology bernard

Automation in haematology bernardBosco Mbonimpa

╠²

Automated cell counters provide several advantages over manual cell counting including objectivity, elimination of errors, higher precision, and ability to measure more parameters. They work using principles of impedance, optical light scattering, or both. Quality control and daily maintenance are important to ensure accurate results. While automated counts are precise, manual review of films is still needed when results are abnormal. Newer automated hematology analyzers can measure over 30 parameters using technologies like flow cytometry.cell-counters1575.ppt.pptx

cell-counters1575.ppt.pptxWaqarRaees

╠²

Wallace Coulter developed the Coulter Principle for counting and sizing microscopic particles like blood cells in the late 1940s-early 1950s. Modern cell counters use various technologies including impedance, absorbance spectrophotometry, optics, fluorescence, conductivity, and monoclonal antibodies. Cell counters must run within specifications to provide accurate results.Automation in clinical hematology

Automation in clinical hematologyTitto Rahim

╠²

The document discusses automated hematology analyzers and their advantages over manual methods. Automated analyzers can measure numerous blood parameters quickly and precisely using various techniques including electrical impedance, light scattering, fluorescence and absorption. They provide counts and indices for red blood cells, white blood cells, platelets, as well as reticulocytes. While automated analyzers offer speed, accuracy and ability to perform multiple tests, they may have issues with abnormal cells and require human examination of flags.Automated cell counter & its quality control

Automated cell counter & its quality controlSaikat Mandal

╠²

Automated hematology analyzers provide several advantages over manual methods including speed, accuracy, precision, and the ability to perform multiple tests on a single sample. They work using various principles such as electrical impedance, optical light scatter, and fluorescence to count and characterize red blood cells, white blood cells, and platelets. Quality control measures like the use of controls analyzed daily and the application of rules like the Westgard rules help monitor the performance of these automated analyzers.Osmotic fragility test pathology... .ppt

Osmotic fragility test pathology... .pptJahanviPatel41

╠²

The document discusses an osmotic fragility test, which measures the susceptibility of red blood cells to hemolysis (rupture) when exposed to saline solutions of varying concentrations. Red blood cells that are more spherical, such as in hereditary spherocytosis, have increased fragility and hemolyze in more dilute solutions. Conversely, conditions like thalassemia and iron deficiency decrease fragility as the cells have a greater surface area. The test can aid in diagnosing conditions like hereditary spherocytosis and thalassemia by noting the saline concentration at which hemolysis begins.RBC morphology and Disease that may be associated with abnormal morphologies.

RBC morphology and Disease that may be associated with abnormal morphologies.Faheem Javed

╠²

This presentation contain information about red blood cell morphology with images and with disease information.Automated cell counters

Automated cell countersRicha Sharma

╠²

There are three main types of cell counting: manual, semi-automated, and automated. Fully automated cell counters use either impedance or optical methods like light scattering to count and classify cells. Automated counting has advantages over manual counting like being objective, eliminating errors, and providing additional parameters. Automated counters can provide a 3, 5, or 7-part differential count based on cell volume, staining properties, and light scattering characteristics. Newer technologies like flow cytometry provide more detailed analysis of cellular features.Updated - Platelet histogram

Updated - Platelet histogramjadcaesar

╠²

The document discusses platelet histogram parameters including MPV, PDW, and P-LCR. It notes that thrombocytosis can present with low MPV and describes how giant platelets and micro RBCs can cause platelet/RBC overlap on histograms. Conditions like thalassemia major can affect WBC, RBC, and platelet parameters. It also mentions that chemotherapy can result in platelet anisocytosis. The document is authored by Caesar Abu Arra and focuses on interpreting platelet histogram results. CBC Histogram DR NARMADA PRASAD TIWARI

CBC Histogram DR NARMADA PRASAD TIWARINarmada Tiwari

╠²

This document provides information about interpreting histograms generated by hematology analyzers when performing complete blood count (CBC) tests. It includes histograms showing normal and abnormal patterns for red blood cells, white blood cells, and platelets. Abnormal indicators are described that may indicate issues like schistocytes, transfusion, autoagglutination, microcytosis, macrocytosis, nucleated red blood cells, atypical lymphocytes, and more. The document emphasizes the importance of correlating histogram findings with peripheral blood smear examination to make an accurate diagnosis.Automated tissue stainer - Xmatrx infinity

Automated tissue stainer - Xmatrx infinityBioGenex

╠²

Xmatrx Infinity is a fully automated molecular pathology workstation designed to accelerate life sciences research and drug discovery and development. It is an open system that allows simultaneous optimization of 40 assay parameters in a single run. The 40 independently thermal cyclable workstations enable any slide-based staining assays, including IHC, ISH, CISH, FISH, multiplexing and co-detection, special stain, in situ PCR and miRNA. The Infinity system adapts and completely automates any manual protocols such as denaturation, hybridization, stringency washes, counter stain and final coverslip to maximize testing capacity, minimize hands-on time and ensure consistent results every time.Quality Assurance in Hematology laboratory

Quality Assurance in Hematology laboratoryMohammed Abdalla Elhassan

╠²

This document discusses quality assurance in hematology laboratories. It defines key terms like accuracy, precision, and components of quality assurance like pre-analytical, analytical, and post-analytical stages. It describes the importance of proper specimen collection and handling in the pre-analytical stage. The analytical stage involves internal and external quality control. Specific controls for hematology analyzers like Latron beads and 6C & retics controls are discussed. The importance of result verification, critical value notification, and collaboration in the post-analytical stage is highlighted. Calibration, proficiency testing, and the role of risk assessment in ensuring patient safety are also summarized.Automated cell counters

Automated cell countersKasturba Medical College

╠²

Dr. Sadaf Khan discusses automated cell counters and complete blood count (CBC) analysis. Automated cell counters have advanced from semi-automated in the 1950s to fully automated today. CBC analysis involves counting red blood cells, white blood cells, platelets, and other parameters. Automated cell counters use various principles including impedance, light scattering, and flow cytometry to analyze CBC samples and provide accurate and efficient results. Proper sample handling and quality control are important to obtain reliable results from automated cell counters.serous fluid Dr shweta [Autosaved].pptx![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

serous fluid Dr shweta [Autosaved].pptxsandeepkumarGarg4

╠²

This document provides information about examining serous fluids, including pleural, pericardial, and ascitic fluids. It discusses the normal formation of serous fluids and how to differentiate transudates from exudates. It outlines various routine tests that can be performed on serous fluids, such as physical examination, microscopic examination including cell counts and differentials, and chemical tests including measurements of protein, glucose, LDH, and others. Approaches to examining different types of serous fluids are also summarized.Automation in hematology part 1

Automation in hematology part 1Dr. Varughese George

╠²

This document discusses automation in hematology. It begins by outlining the necessity for automation in cell counting, diagnosing various blood conditions, and performing multiple tests on a single platform. The document then covers the advantages and disadvantages of automation, including increased speed and accuracy versus high costs. It describes the various principles used in automated hematology analyzers, such as electrical impedance, optical light scattering, and flow cytometry. Finally, it provides details on specific analyzers like the Pentra ES 60 and Pentra DF Nexus. cytology of body fluid

cytology of body fluidMusa Khan

╠²

1. Cytology of body fluids involves examining fluids from various body cavities including cerebrospinal fluid, pleural fluid, peritoneal fluid, pericardial fluid, and synovial fluid. Specimen collection and laboratory analysis includes gross examination, cell counts, biochemical analysis, and microscopic examination.

2. Transudates and exudates are distinguished based on characteristics like protein content and cell differentials. Infection, inflammation, and malignancy can be identified by analyzing changes in fluid characteristics.

3. Cytology of body fluids provides diagnostic information for conditions affecting various organ systems. Proper collection and analysis of physical and chemical properties aids in differential diagnosis.cbc Histogram

cbc HistogramTONY SCARIA

╠²

- The document discusses histograms generated by cell counters that graphically represent cell population data. It focuses on histograms for red blood cells (RBCs), white blood cells (WBCs), and platelets.

- Key parameters for each type of histogram are defined, such as how cells are counted and measured, normal ranges, and flags that indicate potential issues. Common causes for shifts or abnormalities in the histograms are also outlined.

- The information provides guidance on interpreting cell counter histograms and histograms to help evaluate a patient's blood cell counts and detect possible blood disorders or interferences.Automated cell counters: principle and types

Automated cell counters: principle and typesSivaranjini N

╠²

Automated cell counters provide a fast, accurate, and precise method for enumerating blood cells compared to manual methods. There are three main types of automated cell counters - three-part differential counters differentiate cells into granulocytes, lymphocytes, and monocytes/mixed cells; five-part differential counters further differentiate granulocytes into neutrophils, eosinophils, and basophils; and seven-part differential counters can also distinguish nucleated red blood cells and abnormal/atypical cells. The Coulter principle of impedance counting is commonly used and involves suspending cells in a conductive fluid and counting changes in electrical impedance as cells pass through an aperture. Automated cell counters provide various blood cellAutomation in cytology.

Automation in cytology.Manan Shah

╠²

This presentation in mainly focused of understanding of automation and its utility in cytopathology. It will be very usefull for postgraduate in pathology, cytopathologist and cytotechnicians.Automation in Hematology part 2

Automation in Hematology part 2Dr. Varughese George

╠²

This document discusses quality control procedures for automated hematology analyzers. It describes the use of histograms, flags, and quality control measures to ensure accurate results. Key points:

- Histograms provide graphical representations of cell populations to analyze size, distribution, and detect abnormalities. Flags signal when abnormalities are detected to mandate blood smear examination.

- Internal quality control involves continuous validation of test reliability using control samples processed like patient samples. External quality control evaluates comparability to peer laboratories.

- Accuracy measures closeness to true values while precision measures reproducibility. Controls contain same constituents as patient samples to monitor analyzer performance. Results are plotted on Levey-Jennings charts against manufacturer ranges.

- Westgardquality control in clinical pathology

quality control in clinical pathologyIshaque Vadakkethil

╠²

This document discusses quality control in pathology, with a focus on histopathology. It defines key terms like quality control, quality assurance, and defines the goals of a quality system. It outlines the quality assurance cycle and different factors that can influence quality, including pre-analytical, analytical, and post-analytical phases. Specific areas of quality control in histopathology are discussed, including sample collection and handling, tissue processing, section cutting, and staining. Maintaining standards and addressing errors at each step of the histopathology process is important for accurate diagnosis.CSF BIOCHEMICAL EXAMINATION

CSF BIOCHEMICAL EXAMINATIONHussein Al-tameemi

╠²

The document discusses biochemical analysis of cerebrospinal fluid (CSF) in medical laboratories. Routinely tested parameters in CSF include glucose, protein, electrolytes, lactate, and enzymes. Proper handling and centrifugation of CSF samples is important to avoid contamination. Abnormal levels of glucose, protein, lactate and enzymes can indicate conditions like meningitis or tumors. The Pandy's test and Biuret method are described for measuring CSF protein levels, along with normal ranges. Spectrophotometry is used to analyze results from colorimetric assays.Quality assurance in haematology

Quality assurance in haematologyIshwar Bihana

╠²

This document discusses quality assurance in haematology. It defines quality and introduces the concepts of quality control and quality assurance. Quality control aims to minimize errors through statistical sampling and verification of consistent performance. Quality assurance ensures reliable test results through adherence to standards within and outside the laboratory. This includes internal quality control, external quality assessment, and standardization using reference materials and methods. Several examples are provided of potential pre-analytical errors in sample collection, transport, and handling that can affect test results. Adherence to proper procedures is emphasized to avoid issues like hemolysis, clotting, and dilution.05 peripheral blood smear examination

05 peripheral blood smear examination Ajay Agade

╠²

This document provides information about performing and interpreting a peripheral blood smear examination. It discusses preparing the smear, staining it using Romanowsky staining techniques, and systematically examining it under the microscope. The summary includes evaluating red blood cells for abnormalities in size, shape, inclusions and other features. White blood cell differential counts and platelet assessment are also reviewed. The document outlines various morphological abnormalities that may be observed and their potential clinical significance.Apheresis

ApheresisSUNIL KUMAR PEDDANA

╠²

Apheresis is a medical technology in which blood is withdrawn from a donor or patient, separated into components, and at least one component is retained while the remainder is returned to the circulation. It is used to collect blood components like platelets, plasma, and stem cells for transfusion or therapeutic purposes. Apheresis can be performed manually or using automated machines that utilize centrifugation or filtration to separate components. It has various applications including collection of platelets, plasma exchange to remove antibodies or toxins, and stem cell collection for transplantation. Complications are usually minor but may include hypocalcemia, hypotension, and allergic reactions.Compatibility testing

Compatibility testingKalaivaniGanapathy

╠²

This document discusses compatibility testing for blood transfusions, specifically the process of cross matching. Cross matching involves two parts, the major and minor cross matches, to determine compatibility between donor and recipient blood. It describes different methods for performing the saline cross match, including the open slide method and saline tube method. The saline tube method is preferred as it allows detection of agglutination and hemolysis as indicators of incompatibility. Proper testing and cross matching are necessary to ensure a safe transfusion.Reticulocyte count

Reticulocyte countMedina College

╠²

This document provides information on reticluocyte count, which assesses bone marrow erythropoietic activity. It describes how a reticluocyte is an immature red blood cell that contains RNA aggregates. The routine reticluocyte count involves staining a blood sample and counting the number of reticluocytes per 1000 red blood cells under a microscope. Quality control measures and different counting methods using a calibrated disk are discussed. The reticluocyte percentage, absolute count, corrected count, and production index are defined and their clinical significance and reference ranges are explained.QUALITY control in hematology by Dr yogeeta Tanty.pptx

QUALITY control in hematology by Dr yogeeta Tanty.pptxYogeetaTanty1

╠²

This document discusses quality control in hematology. It defines quality as freedom from defects achieved through adherence to standards. Quality assurance ensures reliability of lab tests through standardization. Quality control detects, reduces, and corrects deficiencies in the internal analytical process. Important aspects of quality control in hematology include instrument calibration, monitoring accuracy and precision, and verifying reliable test results. Internal quality control uses controls for immediate decision making while external quality control compares results to other labs. Statistical methods like mean, standard deviation, and Levey Jennings charts are used for quality control assessment.Biomedical Instrumentation auto analyser.pptx

Biomedical Instrumentation auto analyser.pptxDrAyyarKandasamy

╠²

Automated analyzers provide several key advantages over manual testing in clinical laboratories. There are four basic types of automated analyzers: continuous flow, centrifugal, discrete, and dry chemical. They increase testing throughput, improve accuracy and precision, and reduce human error. However, they also require more space and waste than manual methods. Each type has distinct principles, such as using pumps to continuously move fluids or spinning cuvettes to mix and analyze samples simultaneously. Automated analyzers are essential for efficiently processing high test volumes in modern clinical labs.Auto analyzer

Auto analyzerTapeshwar Yadav

╠²

Automated analyzers have advanced diagnostic testing by increasing efficiency and accuracy while reducing human error. There are four basic approaches to automated analyzers: continuous flow analyzers, centrifugal analyzers, discrete auto analyzers, and dry chemical analyzers. Each type has its own principles and advantages such as processing multiple samples simultaneously, using small sample volumes, and eliminating manual steps. Automated analyzers have improved healthcare by providing faster, higher quality, and more standardized test results.More Related Content

What's hot (20)

Updated - Platelet histogram

Updated - Platelet histogramjadcaesar

╠²

The document discusses platelet histogram parameters including MPV, PDW, and P-LCR. It notes that thrombocytosis can present with low MPV and describes how giant platelets and micro RBCs can cause platelet/RBC overlap on histograms. Conditions like thalassemia major can affect WBC, RBC, and platelet parameters. It also mentions that chemotherapy can result in platelet anisocytosis. The document is authored by Caesar Abu Arra and focuses on interpreting platelet histogram results. CBC Histogram DR NARMADA PRASAD TIWARI

CBC Histogram DR NARMADA PRASAD TIWARINarmada Tiwari

╠²

This document provides information about interpreting histograms generated by hematology analyzers when performing complete blood count (CBC) tests. It includes histograms showing normal and abnormal patterns for red blood cells, white blood cells, and platelets. Abnormal indicators are described that may indicate issues like schistocytes, transfusion, autoagglutination, microcytosis, macrocytosis, nucleated red blood cells, atypical lymphocytes, and more. The document emphasizes the importance of correlating histogram findings with peripheral blood smear examination to make an accurate diagnosis.Automated tissue stainer - Xmatrx infinity

Automated tissue stainer - Xmatrx infinityBioGenex

╠²

Xmatrx Infinity is a fully automated molecular pathology workstation designed to accelerate life sciences research and drug discovery and development. It is an open system that allows simultaneous optimization of 40 assay parameters in a single run. The 40 independently thermal cyclable workstations enable any slide-based staining assays, including IHC, ISH, CISH, FISH, multiplexing and co-detection, special stain, in situ PCR and miRNA. The Infinity system adapts and completely automates any manual protocols such as denaturation, hybridization, stringency washes, counter stain and final coverslip to maximize testing capacity, minimize hands-on time and ensure consistent results every time.Quality Assurance in Hematology laboratory

Quality Assurance in Hematology laboratoryMohammed Abdalla Elhassan

╠²

This document discusses quality assurance in hematology laboratories. It defines key terms like accuracy, precision, and components of quality assurance like pre-analytical, analytical, and post-analytical stages. It describes the importance of proper specimen collection and handling in the pre-analytical stage. The analytical stage involves internal and external quality control. Specific controls for hematology analyzers like Latron beads and 6C & retics controls are discussed. The importance of result verification, critical value notification, and collaboration in the post-analytical stage is highlighted. Calibration, proficiency testing, and the role of risk assessment in ensuring patient safety are also summarized.Automated cell counters

Automated cell countersKasturba Medical College

╠²

Dr. Sadaf Khan discusses automated cell counters and complete blood count (CBC) analysis. Automated cell counters have advanced from semi-automated in the 1950s to fully automated today. CBC analysis involves counting red blood cells, white blood cells, platelets, and other parameters. Automated cell counters use various principles including impedance, light scattering, and flow cytometry to analyze CBC samples and provide accurate and efficient results. Proper sample handling and quality control are important to obtain reliable results from automated cell counters.serous fluid Dr shweta [Autosaved].pptx![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

![serous fluid Dr shweta [Autosaved].pptx](https://cdn.slidesharecdn.com/ss_thumbnails/serousfluiddrshwetaautosaved-221213040107-a9b2a766-thumbnail.jpg?width=560&fit=bounds)

serous fluid Dr shweta [Autosaved].pptxsandeepkumarGarg4

╠²

This document provides information about examining serous fluids, including pleural, pericardial, and ascitic fluids. It discusses the normal formation of serous fluids and how to differentiate transudates from exudates. It outlines various routine tests that can be performed on serous fluids, such as physical examination, microscopic examination including cell counts and differentials, and chemical tests including measurements of protein, glucose, LDH, and others. Approaches to examining different types of serous fluids are also summarized.Automation in hematology part 1

Automation in hematology part 1Dr. Varughese George

╠²

This document discusses automation in hematology. It begins by outlining the necessity for automation in cell counting, diagnosing various blood conditions, and performing multiple tests on a single platform. The document then covers the advantages and disadvantages of automation, including increased speed and accuracy versus high costs. It describes the various principles used in automated hematology analyzers, such as electrical impedance, optical light scattering, and flow cytometry. Finally, it provides details on specific analyzers like the Pentra ES 60 and Pentra DF Nexus. cytology of body fluid

cytology of body fluidMusa Khan

╠²

1. Cytology of body fluids involves examining fluids from various body cavities including cerebrospinal fluid, pleural fluid, peritoneal fluid, pericardial fluid, and synovial fluid. Specimen collection and laboratory analysis includes gross examination, cell counts, biochemical analysis, and microscopic examination.

2. Transudates and exudates are distinguished based on characteristics like protein content and cell differentials. Infection, inflammation, and malignancy can be identified by analyzing changes in fluid characteristics.

3. Cytology of body fluids provides diagnostic information for conditions affecting various organ systems. Proper collection and analysis of physical and chemical properties aids in differential diagnosis.cbc Histogram

cbc HistogramTONY SCARIA

╠²

- The document discusses histograms generated by cell counters that graphically represent cell population data. It focuses on histograms for red blood cells (RBCs), white blood cells (WBCs), and platelets.

- Key parameters for each type of histogram are defined, such as how cells are counted and measured, normal ranges, and flags that indicate potential issues. Common causes for shifts or abnormalities in the histograms are also outlined.

- The information provides guidance on interpreting cell counter histograms and histograms to help evaluate a patient's blood cell counts and detect possible blood disorders or interferences.Automated cell counters: principle and types

Automated cell counters: principle and typesSivaranjini N

╠²

Automated cell counters provide a fast, accurate, and precise method for enumerating blood cells compared to manual methods. There are three main types of automated cell counters - three-part differential counters differentiate cells into granulocytes, lymphocytes, and monocytes/mixed cells; five-part differential counters further differentiate granulocytes into neutrophils, eosinophils, and basophils; and seven-part differential counters can also distinguish nucleated red blood cells and abnormal/atypical cells. The Coulter principle of impedance counting is commonly used and involves suspending cells in a conductive fluid and counting changes in electrical impedance as cells pass through an aperture. Automated cell counters provide various blood cellAutomation in cytology.

Automation in cytology.Manan Shah

╠²

This presentation in mainly focused of understanding of automation and its utility in cytopathology. It will be very usefull for postgraduate in pathology, cytopathologist and cytotechnicians.Automation in Hematology part 2

Automation in Hematology part 2Dr. Varughese George

╠²

This document discusses quality control procedures for automated hematology analyzers. It describes the use of histograms, flags, and quality control measures to ensure accurate results. Key points:

- Histograms provide graphical representations of cell populations to analyze size, distribution, and detect abnormalities. Flags signal when abnormalities are detected to mandate blood smear examination.

- Internal quality control involves continuous validation of test reliability using control samples processed like patient samples. External quality control evaluates comparability to peer laboratories.

- Accuracy measures closeness to true values while precision measures reproducibility. Controls contain same constituents as patient samples to monitor analyzer performance. Results are plotted on Levey-Jennings charts against manufacturer ranges.

- Westgardquality control in clinical pathology

quality control in clinical pathologyIshaque Vadakkethil

╠²

This document discusses quality control in pathology, with a focus on histopathology. It defines key terms like quality control, quality assurance, and defines the goals of a quality system. It outlines the quality assurance cycle and different factors that can influence quality, including pre-analytical, analytical, and post-analytical phases. Specific areas of quality control in histopathology are discussed, including sample collection and handling, tissue processing, section cutting, and staining. Maintaining standards and addressing errors at each step of the histopathology process is important for accurate diagnosis.CSF BIOCHEMICAL EXAMINATION

CSF BIOCHEMICAL EXAMINATIONHussein Al-tameemi

╠²

The document discusses biochemical analysis of cerebrospinal fluid (CSF) in medical laboratories. Routinely tested parameters in CSF include glucose, protein, electrolytes, lactate, and enzymes. Proper handling and centrifugation of CSF samples is important to avoid contamination. Abnormal levels of glucose, protein, lactate and enzymes can indicate conditions like meningitis or tumors. The Pandy's test and Biuret method are described for measuring CSF protein levels, along with normal ranges. Spectrophotometry is used to analyze results from colorimetric assays.Quality assurance in haematology

Quality assurance in haematologyIshwar Bihana

╠²

This document discusses quality assurance in haematology. It defines quality and introduces the concepts of quality control and quality assurance. Quality control aims to minimize errors through statistical sampling and verification of consistent performance. Quality assurance ensures reliable test results through adherence to standards within and outside the laboratory. This includes internal quality control, external quality assessment, and standardization using reference materials and methods. Several examples are provided of potential pre-analytical errors in sample collection, transport, and handling that can affect test results. Adherence to proper procedures is emphasized to avoid issues like hemolysis, clotting, and dilution.05 peripheral blood smear examination

05 peripheral blood smear examination Ajay Agade

╠²

This document provides information about performing and interpreting a peripheral blood smear examination. It discusses preparing the smear, staining it using Romanowsky staining techniques, and systematically examining it under the microscope. The summary includes evaluating red blood cells for abnormalities in size, shape, inclusions and other features. White blood cell differential counts and platelet assessment are also reviewed. The document outlines various morphological abnormalities that may be observed and their potential clinical significance.Apheresis

ApheresisSUNIL KUMAR PEDDANA

╠²

Apheresis is a medical technology in which blood is withdrawn from a donor or patient, separated into components, and at least one component is retained while the remainder is returned to the circulation. It is used to collect blood components like platelets, plasma, and stem cells for transfusion or therapeutic purposes. Apheresis can be performed manually or using automated machines that utilize centrifugation or filtration to separate components. It has various applications including collection of platelets, plasma exchange to remove antibodies or toxins, and stem cell collection for transplantation. Complications are usually minor but may include hypocalcemia, hypotension, and allergic reactions.Compatibility testing

Compatibility testingKalaivaniGanapathy

╠²

This document discusses compatibility testing for blood transfusions, specifically the process of cross matching. Cross matching involves two parts, the major and minor cross matches, to determine compatibility between donor and recipient blood. It describes different methods for performing the saline cross match, including the open slide method and saline tube method. The saline tube method is preferred as it allows detection of agglutination and hemolysis as indicators of incompatibility. Proper testing and cross matching are necessary to ensure a safe transfusion.Reticulocyte count

Reticulocyte countMedina College

╠²

This document provides information on reticluocyte count, which assesses bone marrow erythropoietic activity. It describes how a reticluocyte is an immature red blood cell that contains RNA aggregates. The routine reticluocyte count involves staining a blood sample and counting the number of reticluocytes per 1000 red blood cells under a microscope. Quality control measures and different counting methods using a calibrated disk are discussed. The reticluocyte percentage, absolute count, corrected count, and production index are defined and their clinical significance and reference ranges are explained.QUALITY control in hematology by Dr yogeeta Tanty.pptx

QUALITY control in hematology by Dr yogeeta Tanty.pptxYogeetaTanty1

╠²

This document discusses quality control in hematology. It defines quality as freedom from defects achieved through adherence to standards. Quality assurance ensures reliability of lab tests through standardization. Quality control detects, reduces, and corrects deficiencies in the internal analytical process. Important aspects of quality control in hematology include instrument calibration, monitoring accuracy and precision, and verifying reliable test results. Internal quality control uses controls for immediate decision making while external quality control compares results to other labs. Statistical methods like mean, standard deviation, and Levey Jennings charts are used for quality control assessment.Similar to ADVIA Concept & Principles (20)

Biomedical Instrumentation auto analyser.pptx

Biomedical Instrumentation auto analyser.pptxDrAyyarKandasamy

╠²

Automated analyzers provide several key advantages over manual testing in clinical laboratories. There are four basic types of automated analyzers: continuous flow, centrifugal, discrete, and dry chemical. They increase testing throughput, improve accuracy and precision, and reduce human error. However, they also require more space and waste than manual methods. Each type has distinct principles, such as using pumps to continuously move fluids or spinning cuvettes to mix and analyze samples simultaneously. Automated analyzers are essential for efficiently processing high test volumes in modern clinical labs.Auto analyzer

Auto analyzerTapeshwar Yadav

╠²

Automated analyzers have advanced diagnostic testing by increasing efficiency and accuracy while reducing human error. There are four basic approaches to automated analyzers: continuous flow analyzers, centrifugal analyzers, discrete auto analyzers, and dry chemical analyzers. Each type has its own principles and advantages such as processing multiple samples simultaneously, using small sample volumes, and eliminating manual steps. Automated analyzers have improved healthcare by providing faster, higher quality, and more standardized test results.19039 automated analyser lect_1__instrumentation lect 2nd yr mt_2nd semester

19039 automated analyser lect_1__instrumentation lect 2nd yr mt_2nd semesterguayacan87

╠²

This document discusses different types of automated analyzers used in diagnostic laboratories, including their basic approaches, advantages, and disadvantages. It describes continuous flow analyzers, centrifugal analyzers, discrete auto analyzers, and dry chemical analyzers. Continuous flow analyzers were an early approach but had issues like wasting reagents. Centrifugal analyzers can rapidly analyze batches of samples but only one test type at a time. Discrete auto analyzers are the most versatile as they can run multiple tests on one sample or multiple samples on one test. Dry chemical analyzers use reagent slides but samples with high protein can cause errors. Future trends include more system integration, miniaturization, and artificial intelligence in automated analyzers.PHOXEN

PHOXENAndrey Kulikov

╠²

The document describes 6 models of the Stat Profile pHOx blood gas and critical care analyzer that provide different test menus and capabilities. The analyzers offer rapid turnaround times of 45-52 seconds and sample volumes as low as 45 microliters. Key features include an all-liquid calibration cartridge that eliminates gas tanks, automated on-board quality control, and connectivity to laboratory information systems. The analyzers provide physicians with comprehensive patient diagnostics using a compact point-of-care design.istatprocedure.PDF

istatprocedure.PDFArnoldoFelix3

╠²

This procedure manual provides guidelines for using the i-STAT system to analyze blood samples. It describes the

components of the i-STAT system including the analyzers, cartridges, test strips and data management software. It provides

details on supplies, storage requirements, suitable blood specimens, collection and handling procedures, quality control

testing, and interpretation of results. The goal is to customize this template for a site's specific policies and procedures for

point-of-care blood analysis using the i-STAT system.Good chromatography practices - requisites and guidelines

Good chromatography practices - requisites and guidelinessuprajakotam

╠²

Analytical techniques and instrumental methods Automation.pptx

Automation.pptxHarpreetBurmi1

╠²

This document discusses automation in biochemistry laboratory testing. It defines automation as using instruments to perform tests with minimal human involvement. There are different phases and types of analyzers used in automation. Continuous flow analyzers and discrete autoanalyzers are described in detail. The document also discusses specific automated machines used in the author's laboratory, including their main components and functions. Benefits of automation include higher throughput, reduced errors and variability, lower sample/reagent use, and labor savings, though automation has high initial costs.Automation in Clinical Biochemistry.pptx

Automation in Clinical Biochemistry.pptxAmit kumar Singh

╠²

Automation in clinical biochemistry provides several benefits such as reducing workload, increasing throughput, improving accuracy, and eliminating human error. There are various steps in automated analysis including sample collection, identification, delivery, preparation, and analysis. Automation uses laboratory instruments and equipment to perform assays with minimal human involvement. Common types of automated analyzers are continuous flow analyzers, discrete analyzers, batch analyzers, and random access analyzers. Automation allows for processing of larger sample volumes and multiple tests per sample.Automation in Biochemistry (Autoanalyzers)

Automation in Biochemistry (Autoanalyzers)Pradeep Singh Narwat

╠²

Automation in biochemistry refers to using instruments to perform biochemical tests with minimal human involvement. Automated systems can perform many steps like sample handling, reagent addition, reaction incubation, and measurement that were previously done manually. The main types of automated analyzers are continuous flow analyzers, discrete autoanalyzers, and random access analyzers. Continuous flow analyzers pass samples and reagents sequentially through a single analytical pathway. Discrete autoanalyzers separate each sample and reagent in individual containers, allowing multiple tests per sample. Random access analyzers perform tests on batches of samples, selecting tests for each sample. Automated systems provide benefits like higher throughput, reduced variability, and less manual labor, but also have high initial costs.DMLT (2nd Year) : Automation in Clinical Biochemistry and POCT - Some basic c...

DMLT (2nd Year) : Automation in Clinical Biochemistry and POCT - Some basic c...PrabhatNigam6

╠²

Automation in clinical biochemistry - vacuum extraction accessories, barcoded specimen collection, laboratory information system (LIS), conveyor belt systems, pneumatic tube systems, open & closed system, Continuous flow processing, discrete processing, batch analyzer, random access analyzer, wet & dry analyzers

POCT - laboratory type, cartridge bases, strip based, glucometer, QC of POCT

Automatic stationary sampler-Liquistation CSF34

Automatic stationary sampler-Liquistation CSF34Edress Hauser: Flow Meter, Level, Pressure, Temperature

╠²

Automatic stationary sampler. Controller with up to four measuring channels and optional digital. Email: lam.nguyen@vietan-enviro.com HP: 0945 293292URINE AND BF AUTOMATION.pptx

URINE AND BF AUTOMATION.pptxMicrisDizon

╠²

This document discusses the automation of urinalysis and body fluid analysis. It notes that automation improves reproducibility, standardization, and productivity while reducing subjectivity. Automated instruments can perform sample processing, reagent strip analysis, urine sediment analysis, and reporting. Advantages include reduced hands-on time, online computer capabilities, data storage, and flagging of abnormal results. Semi-automated instruments still require some operator involvement while fully automated systems can load many samples and operate walk-away. Automated microscopy provides standardized, quantitative results faster than manual methods. Combining automated chemistry analyzers and cell analyzers into integrated systems allows a complete urinalysis to be performed automatically.Automated Method of Analysis

Automated Method of AnalysisProf. Sanket P. Shinde

╠²

Complete automation will lead to human prohibition in pharma industries.

Analytical techniques in drug discovery and development stage generate large amounts of data that is not possible for humans to statistically analyze.Hplc ppt

Hplc pptShweta Tyagi

╠²

High Performance Liquid Chromatography (HPLC) is a separation technique that uses pumps to force a liquid mobile phase through a column packed with solid particles. Sample components interact differently with the stationary and mobile phases allowing separation. HPLC instruments consist of pumps, injectors, columns, detectors and computers. Samples are injected and the separated components are detected and data is analyzed to identify and quantify the components. HPLC is used in various fields to analyze complex mixtures like pharmaceuticals, chemicals, and biological samples.High performance liquid chromatography

High performance liquid chromatographyVaishali Dudhabale

╠²

This presentation involves all d information about HPLC and its important components useful in academic sessions.Flow control software for flow Chemistry overview from Uniqsis

Flow control software for flow Chemistry overview from UniqsisPaul Pergande

╠²

FlowControl software allows researchers to program Uniqsis flow chemistry equipment and automate sequences of experiments. It can control a custom system built from Uniqsis modules like pumps, reactors, and fraction collectors. Experiments are planned by defining reagents, temperatures, times and fraction collection. FlowControl monitors experiments in real-time, logs data, and allows viewing past results. It provides flexible, automated control of Uniqsis flow chemistry systems.RX-monaco.pdf

RX-monaco.pdfMarketingtechnobmed

╠²

The RX monaco is a fully automated clinical chemistry analyzer capable of performing 170 tests per hour. It has a discrete, random access design and features include a large test menu, quality control capabilities, intuitive Windows-based software, and remote diagnostics. The analyzer provides cost-effective and reliable testing for small to medium sized clinical laboratories.What is Nephelometry,and a fully automated Nephlometer analyzer for protein a...

What is Nephelometry,and a fully automated Nephlometer analyzer for protein a...Shahid Nawaz

╠²

Nephelometry is commonly used to determine protein levels in body fluids like serum and urine. It works by measuring the light scattered by antigen-antibody complexes formed when a sample containing antigen is mixed with corresponding antiserum. The amount of light scattered is proportional to the antigen concentration in the sample. This document provides instructions for using a nephelometer to test samples for C-reactive protein (CRP) levels, including preparing reagents and standards, running samples, generating a calibration curve from standards, and recording results. CRP levels between 0.0-1.0 mg/dL are considered normal.Auto analyser

Auto analyserMicky782523

╠²

This ppt describes the auto analyser which is used in biochemistry department in hospitals for analysing the composition of various constituents in the blood and other body fluids.Automatic stationary sampler-Liquistation CSF34

Automatic stationary sampler-Liquistation CSF34Edress Hauser: Flow Meter, Level, Pressure, Temperature

╠²

ADVIA Concept & Principles

- 1. Presented by: NARGIS KHOSO 14th Oct 2015

- 3. -What is ADVIA2120i? -Components of ADVIA2120i -Principle -Reagents and Loading reagents -Running samples -Quality Control -Maintenance

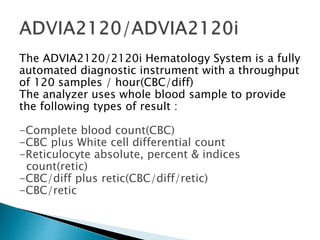

- 4. The ADVIA2120/2120i Hematology System is a fully automated diagnostic instrument with a throughput of 120 samples / hour(CBC/diff) The analyzer uses whole blood sample to provide the following types of result : -Complete blood count(CBC) -CBC plus White cell differential count -Reticulocyte absolute, percent & indices count(retic) -CBC/diff plus retic(CBC/diff/retic) -CBC/retic

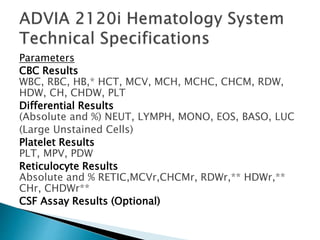

- 5. Parameters CBC Results WBC, RBC, HB,* HCT, MCV, MCH, MCHC, CHCM, RDW, HDW, CH, CHDW, PLT Differential Results (Absolute and %) NEUT, LYMPH, MONO, EOS, BASO, LUC (Large Unstained Cells) Platelet Results PLT, MPV, PDW Reticulocyte Results Absolute and % RETIC,MCVr,CHCMr, RDWr,** HDWr,** CHr, CHDWr** CSF Assay Results (Optional)

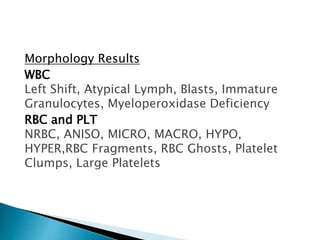

- 6. Morphology Results WBC Left Shift, Atypical Lymph, Blasts, Immature Granulocytes, Myeloperoxidase Deficiency RBC and PLT NRBC, ANISO, MICRO, MACRO, HYPO, HYPER,RBC Fragments, RBC Ghosts, Platelet Clumps, Large Platelets

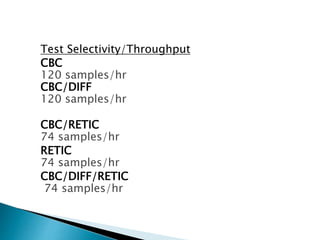

- 7. Test Selectivity/Throughput CBC 120 samples/hr CBC/DIFF 120 samples/hr CBC/RETIC 74 samples/hr RETIC 74 samples/hr CBC/DIFF/RETIC 74 samples/hr

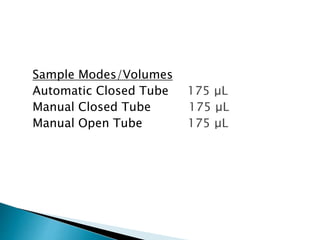

- 8. Sample Modes/Volumes Automatic Closed Tube 175 ╬╝L Manual Closed Tube 175 ╬╝L Manual Open Tube 175 ╬╝L

- 9. Data Management Database 10,000-patient storage capacity including graphics Workstation Specifications Computer Windows 2000,® 40-gigabyte hard disk drive,256-MB memory, CD-RW, full-size keyboard

- 10. The ADVIA2021i Hematology System is made up of 2 major components : A- The analyzer contains all the electronic, pneumatic, hydraulic & sampler mechanisms, as well as the on board reagent storage for all reagents: Defoamer, Wash solution except Sheath RINSE. The waste system is a sub component of analyzer.

- 11. 1 Auto sampler 2 Manual open-tube sampler 3 Manual closed-tube sampler 4 UnifluidicsŌäó technology 5 Perox optical assembly 6 RBC optical assembly 7 Hgb colorimeter assembly 8 Sample, sheath, and diaphragm pumps 9 Reagents, sheath, wash, and rinse 10 Vacuum and pressure regulator knobs 11 Touchpad 12 Manual barcode reader 13 Waste removal system

- 12. B. Personal Computer(PC) includes a monitor , mouse, keyboard & interconnect cabling

- 13. The auto sampler automatically transports, mixes, identifies & aspirates samples in closed tubes. The auto sampler is a rack-style sampler with a capacity of 150 sample tubes: 15 racks of 10 tubes. The individual racks are barcoded for rack and position numbers.

- 14. In open tube aspiration, sample probe is immersed in to the specimen. Pressing the push to aspirate plate , starts the sampling

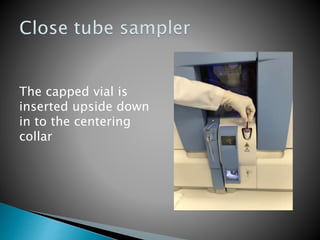

- 15. The capped vial is inserted upside down in to the centering collar

- 16. This block is made up of 8 plates which are pathway for fluid, air flow, valves & reaction chambers. Reaction Chambers are: -Hb reaction chamber -Baso reaction chamber -RBC reaction chamber -Retic reaction chamber -Perox reaction chamber

- 17. Its made up of 2 ceramic discs The rear disk is stationary . The front disc rotates to shear or divide sample into appropriate aliquots for analysis

- 18. The perox optical assembly directs light from halogen lamp to the perox flow cell. The use of a sheath stream in the flow cell allows a cell-by-cell measurement of light scatter and absorption.

- 19. The laser optical assembly uses a laser light source. This optical assembly is shared by RBC/Plt, retic, and baso/lobularity channels. The use of a sheath stream in the flow cell allows cell-by-cell measurement of low- and high-angle light scattering and absorption.

- 20. The hemoglobin colorimeter assembly takes voltage readings that correspond to the amount of transmitted light that passes through the reaction chamber. The system uses the readings to derive the hemoglobin concentration.

- 21. The perox sample & sheath pumps are located on the left side of the analyzer. The RBC/baso/retic sample & sheath pumps are located on the right side of the analyzer.

- 22. The touchpad, located on the lower right of the analyzer, by which you operate the analyzer. On ŌĆō Provides power to the analyzer assemblies and power supplies. After On is pressed, samples through the manual open- and closed-tube samplers can be processed within 2.5 minutes, while samples through the auto sampler can begin processing within four minutes. Standby ŌĆō Sets the analyzer to a lower power state. To exit, press Standby. Start/Stop Sampler ŌĆō Starts the auto sampler operation or stops the auto sampler. Eject Rack ŌĆō Moves all racks within the auto sampler into the output queue. Rack in Sampler ŌĆō Lights up when a sample rack is in the auto sampler, including the input queue. Off ŌĆō Turns off the

- 23. The manual barcode reader is used to enter information from labels on sample tubes, reagent containers, controls, and calibrators.

- 24. All analyzer waste is stored in an 11-liter waste container. This container can be a stand-alone container, which has to be emptied manually, or part of the automatic waste removal system. When the fluid level in either of the containers reaches the maximum-level line (app. 8 liters), an error message appears on the Status line on the personal computer monitor. The analyzer will not aspirate any more samples until the waste container is emptied.

- 26. Laminar flow is induced by injecting a slow moving sample dilution into a stream of fast- moving sheath fluid which prevents mixing. The sheath fluid surrounds the diluted sample and narrows it, so that cells flow through the sensing zone in single fileŌĆ”this process is known as hydrodynamic focusing.

- 28. CBC TIMEPAC DIFF TIMEPAC EZ Wash PEROX SHEATH SHEATTH RINSE DEFOAMER AUTO RETIC

- 31. To run patient samples from the manual open tube sampler: 1.Run samples in the following order : a. Controls(control label) optional b. Patient samples(sample ID label) 2.Scan the tube label or enter the sample information in the manual sample ID tab

- 32. NOTE : Ensure the sample ID displays on the status line before aspirating a sample 4.Aspirate the sample a. Position tube so that probe is immersed into mixed well sample b. Press the aspirate plate sample light flashes during aspiration ,when it stops flashing , remove tube 5.Validate results when available

- 33. Recommended controls are ADVIA TESTpoint Haematology Controls (Low, Normal and High) that should be keep and store at 2-5 degree C. *Run controls at the start of the patient workload, evaluate all controls before reporting patient results. Allow to reach the controls room temperature before use. *Mix controls properly before run. *Scan tube barcode by barcode reader *Sampler probe is immersed in to mix well sample only deep enough (Approximately 0.25 inch) *Press the aspirate plate.

- 34. Daily Maintenance *System wash Time 6.5 min Analyser mode should be ready to run At utilities menu, select Hydrolytic function Select system wash, select 1 cycle and press Start NOTE: Automatic wash cycle has to be at least 3 cycles a day.

- 35. Clean the shear Valve and aspiration pathway in the UFC(Unified Fluid Circuit) by using 3% bleach and Distilled water (DW)

- 36. Replace both sheath filter 1. PEROX filter (0.45 Um) 2. Laser side Filter (0.22 Um) Clean air filter Clean 50Um plunger

- 37. Replace 1000Um plunger Replace 4 drain filter

- 38. ’üĮTHANK YOU