AFS WMS Traceability

- 1. AFS TECHNOLOGIES WMS FEATURES Traceability: Compliance without sacrificing productivity

- 2. AFS TECHNOLOGIES WMS FEATURES Traceabilty Tracing history of an item by means of documented recorded identification. âĒ GS1 Global Traceability Standard defines minimum set of traceability requirements within business processes to achieve full chain traceability. âĒ From grower to manufacturer. To warehouse and final end source. âĒ In event of food outbreak, sharing of traceability information between trading partners in supply chain is critical to ensure a targeted and effective recall.

- 3. AFS TECHNOLOGIES WMS FEATURES âĒ Critical data tracked from beginning to end and throughout the supply chain. âĒ Linking the flow of information to physical products.

- 4. AFS TECHNOLOGIES WMS FEATURES Features Features in WMS allow for ease capturing data and visibility, without increasing labor. âĒ GS1 & GTIN (Global Trade Item Number) âĒ Single Scan Traceability âĒ PTI Compliance (Produce Traceability Initiative) âĒ Reporting and Visibility âĒ Freeze Product Lot

- 5. AFS TECHNOLOGIES WMS FEATURES Features GS1 & GTIN (Global Trade Item Number) GTIN is an identifier developed by GS1. Brand owners assign GTIN to their products to provide full supply Global Trade Item Number chain visibility. âĒ Supported Throughout All Activities of WMS âĒ Scanning GS1 and UCC-128 Barcodes allows packers and manufacturers to include multiple data elements in the same single barcode â like GTIN, Lot and Quantity Single scan increases traceability & productivity

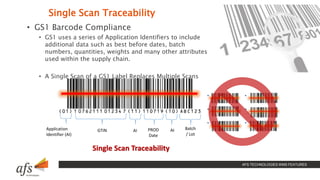

- 6. AFS TECHNOLOGIES WMS FEATURES Single Scan Traceability Application Identifier (AI) GTIN AI PROD Date AI Batch / Lot âĒ Product Code âĒ Quantity âĒ Batch / Lot âĒ Catch Weight âĒ Production Date âĒ Expiry Date Single Scan Traceability âĒ GS1 Barcode Compliance âĒ GS1 uses a series of Application Identifiers to include additional data such as best before dates, batch numbers, quantities, weights and many other attributes used within the supply chain. âĒ A Single Scan of a GS1 Label Replaces Multiple Scans

- 7. AFS TECHNOLOGIES WMS FEATURES Features PTI Compliance (Produce Traceability Initiative) PTI Case-Level Electronic Traceability Ensures Effectiveness of Traceback Procedures âĒ Hybrid Pallet Tags (Inbound/Outbound) âĒ Voice Pick Box Codes âĒ EDI/ASN Compliance Transmissions Standardized industry approach enhances speed & efficiency

- 8. AFS TECHNOLOGIES WMS FEATURES Features Reporting and Visibility âĒ Lot Recall and History Reports âĒ Lookup by Product Lot Ease identifying & locating inventory

- 9. AFS TECHNOLOGIES WMS FEATURES Features Freeze Product Lot âĒ Place Hold Status on Product Lot âĒ Order by Product Lot âĒ Order by Status Prevent inventory being shipped due to product outbreak

- 10. AFS TECHNOLOGIES WMS FEATURES Contact: AFS WMS Product Manager â Fran Rifkin

Editor's Notes

- #6: GTIN is an identifier developed by GS1. Brand owners assign GTIN to their products to provide full supply Global Trade Item Number chain visibility. A product must be configured for Lot to also be configured for GTIN. If the product is configured for GTIN, then when inventory is received or created the GTIN will be required for that product. Scanning GS1 and UCC-128 (Multi-Data) Barcodes. These barcodes allow manufacturer or packers to include multiple data elements in the same single barcode. For example, a meat packer may include the GTIN, lot, weight, pack date, and a box serial number. A produce packer, may include the GTIN, lot, and quantity on the pallet. A manufacturer may use a standard shipping container code for the pallet identification. Having the ability to âgrabâ all this data with a single scan can greatly increase productivity, traceability, and a return on WMS investment. With the release of Enterprise WMS 2014, the system parses ALL the current application identifiers (or AI for short) and will react to and store data relative to the product including GTIN, lot, weight (in kilos or pounds), count in container, pack date, expiration date, serial number, and the shipping container depending on the configuration of the product. These barcodes can also reference pallets, pallet contents, or individual cases. This means that if a GS1 barcode is on the pallet for the GTIN, lot, and quantity, a single scan will capture ALL that information without having to enter the GTIN, or the lot, or even the quantity on the pallet. This element plays a critical role in standards in the Product Traceability Initiative. In short, this can provide âsingle scanâ traceability. Â

- #7: while developing a standardized industry approach to enhance the speed and efficiency of traceability systems for the future. Enterprise WMS 2014 includes complete compliance to ALL seven milestones. Functionality which gives compliance includes: PTI Hybrid Pallet. Handles the inbound and outbound processing of PTI defined Hybrid Pallet Tags, including: Implementing a barcode already widely used in the food industry (GS1) Using existing GS1 Standard data elements inside the barcode (scanning GS1 and UCC128 Labels) Minimizing the information shown on the label to attain supply chain traceability Determining what information is necessary on the label Creating labels that meet the needs of the entire supply chain Providing receivers with standards from which they can build their pallet label scanning processes Voice Pick Box Codes. Per PTI technical best practices, customers using voice picking can confirm individual box GTIN/Lot information by use of a Voice Pick Box code. On inbound the WMS system calculates and stores Voice Pick Box codes for use later in the voice pick process. On outbound the WMS system validates and associates GTIN/Lot information from the Voice Pick Box Codes. PTI Box Labels. Individual case labels printed per quantity for an item.Â

- #8: while developing a standardized industry approach to enhance the speed and efficiency of traceability systems for the future. Enterprise WMS 2014 includes complete compliance to ALL seven milestones. Functionality which gives compliance includes: PTI Hybrid Pallet. Handles the inbound and outbound processing of PTI defined Hybrid Pallet Tags, including: Implementing a barcode already widely used in the food industry (GS1) Using existing GS1 Standard data elements inside the barcode (scanning GS1 and UCC128 Labels) Minimizing the information shown on the label to attain supply chain traceability Determining what information is necessary on the label Creating labels that meet the needs of the entire supply chain Providing receivers with standards from which they can build their pallet label scanning processes Voice Pick Box Codes. Per PTI technical best practices, customers using voice picking can confirm individual box GTIN/Lot information by use of a Voice Pick Box code. On inbound the WMS system calculates and stores Voice Pick Box codes for use later in the voice pick process. On outbound the WMS system validates and associates GTIN/Lot information from the Voice Pick Box Codes. PTI Box Labels. Individual case labels printed per quantity for an item.Â