Aggregate planning

- 2. Aggregate planning ï Aggregate planning involves planning the best quantity to produce in the intermediate-range horizon (3 months to one year) ï Aggregate production planning is the process of determining output levels of product groups over the next 6 to 18 months period.

- 3. Objectives of Aggregate Planning ï§ The overall objective is to balance conflicting objectives involving customer service, work force stability, cost and profit. ï§ To establish company-wide strategic plan for allocating resources. ï§ To develop an economic strategy to meet customer demand.

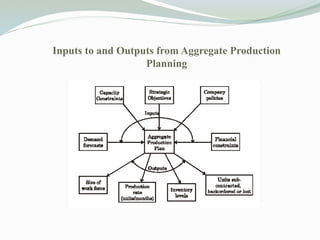

- 4. Inputs to and Outputs from Aggregate Production Planning

- 5. Importance of Aggregate Plans ï The various inputs to aggregate plans that affect the performance of production and operations managers are: i. Engineering ii. Materials iii. Operations iv. Marketing and distribution v. Accounting and finance vi. Human resources

- 6. Aggregate Planning or Aggregate Capacity Planning ï Need for Aggregate Capacity Planning 1. It facilitates fully loaded facilities and minimizes overloading and underloading and keeps production costs low. 2. Adequate production capacity is provided to meet expected aggregate demand. 3. Orderly and systematic transition of production capacity to meet the peaks and valleys of expected customer demand is facilitated. 4. In times of Scarce resources, getting the maximum output for the amount of resources is enhanced. 5. To manage change in operations management by planning for production resources that adapt to the changes in customer demand.

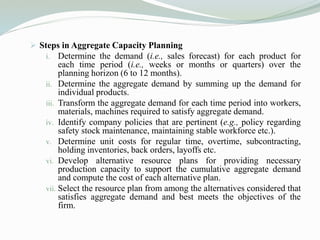

- 7. ï Steps in Aggregate Capacity Planning i. Determine the demand (i.e., sales forecast) for each product for each time period (i.e., weeks or months or quarters) over the planning horizon (6 to 12 months). ii. Determine the aggregate demand by summing up the demand for individual products. iii. Transform the aggregate demand for each time period into workers, materials, machines required to satisfy aggregate demand. iv. Identify company policies that are pertinent (e.g., policy regarding safety stock maintenance, maintaining stable workforce etc.). v. Determine unit costs for regular time, overtime, subcontracting, holding inventories, back orders, layoffs etc. vi. Develop alternative resource plans for providing necessary production capacity to support the cumulative aggregate demand and compute the cost of each alternative plan. vii. Select the resource plan from among the alternatives considered that satisfies aggregate demand and best meets the objectives of the firm.

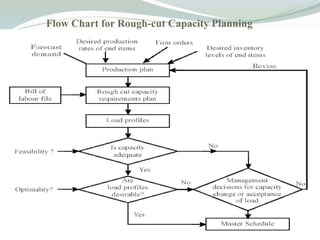

- 8. Approaches to Aggregate Planning 1. Top down approach 2. A bottom-up approach or subplan consolidation approach ï Rough-cut Capacity Planning This is done in conjunction with the tentative master production schedule to test its feasibility in terms of capacity before the master production schedule (MPS) is finalised.

- 9. Flow Chart for Rough-cut Capacity Planning

- 10. Capacity Planning and Capacity Requirement Planning (CRP) ï Production capacity is defined as the maximum production rate of a facility or a plant. ï Types of Capacity 1. Fixed capacity 2. Adjustable capacity 3. Design capacity 4. System capacity 5. Potential capacity 6. Immediate capacity 7. Effective capacity 8. Normal capacity or rated capacity 9. Actual or utilised capacity

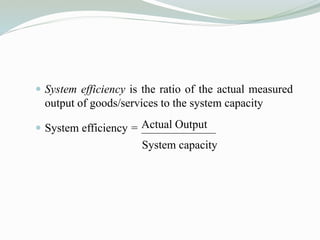

- 11. Actual Output ï System efficiency is the ratio of the actual measured output of goods/services to the system capacity ï System efficiency = System capacity

- 12. ï Capacity Decisions ï Major considerations in capacity decisions are a. What size of plant? How much capacity to install? b. When capacity is needed? When to phase-in capacity or phase-out capacity? c. At what cost? How to budget for the cost? ï Factors Affecting Determination of Plant Capacity 1. Market demand for a product/service. 2. The amount of capital that can be invested. 3. Degree of automation desired. 4. Level of integration (i.e., vertical integration). 5. Type of technology selected. 6. Flexibility for capacity additions.

- 13. Capacity Planning ï Capacity planning involves activities such as: a. Assessing existing capacity b. Forecasting future capacity needs c. Identifying alternative ways to modify capacity d. Evaluating financial, economical and technological capacity alternatives e. Selecting a capacity alternative most suited to achieve the strategic mission of the firm. Capacity planning involves capacity decisions that must merge consumer demands with human, material and financial resources of the organization.

- 14. 4 Types of Capacity Planning are: âĒ Long term Capacity Planning âĒ Short-term Capacity Planing âĒ Finite Capacity Planning âĒ Infinite Capacity Planning. ï Two catagories of factors affecting capacity planning are: âĒ Controllable Factors âĒ Less Controllable Factors. ï Capacity Requirement Planning (CRP): A technique to determine the labour and equipment capacities needed to meet the objectives.

- 15. Capacity Requirement Planning (CRP) Process Capacity Requirement Planning Process (Flow Chart)

- 16. Master Production Scheduling ï Sets the quantity of each finished product to be completed in each time period of the short range planning horizon. ï Objectives of Master Production Scheduling 1. To schedule end items to be completed promptly and when promised to customers. 2. To avoid overloading or underloading the production facility so that production capacity is efficiently utilized and low production costs result.

- 17. Functions of MPS: âĒ Translating aggregate plans âĒ Evaluating alternative master schedules âĒ Generating material and capacity requirements âĒ Facilitating information processing âĒ Maintaining priorities âĒ Utilizing the capacity effectively.

- 18. Master Production Schedule - Flow Chart

- 19. Guidelines for Master Scheduling 1. Work from an aggregate production plan 2. Schedule common modules when possible 3. Load facilities realistically 4. Release orders on a timely basis 5. Monitor inventory levels closely 6. Reschedule as required

- 20. MPS in Produce-to-stock and Produce-to- order Firms ï The elements of the MPS that are affected by the type of production system are: a. Demand management b. Lot-sizing c. Number of products to be scheduled (product-mix).

- 21. Practical Problems ï A work centre operates 5 days a week on a 2 shifts per day basis, each shift of 8 hours duration. There are five machines of the same capacity in this work centre. If the machines are utilized 80 % of the time at a system efficiency of 90%, what is the rated output in standard hours per week. ï A steel plant has a design capacity of 50,000 tons of steel per day, effective capacity of 40,000 tons of steel per day and an actual output of 36,000 tons of steel per day. Compute the efficiency of the plant and its utilization.

- 22. ï The following is a tentative master schedule for four weeks: The bill of Labour in key work centres for the companyâs three major products A, B and C is as below: Product Week 1 Week 2 Week 3 Week 4 A 3000 4000 1200 2500 B 2000 1500 3000 3500 C 1200 1800 2500 2000

- 23. Determine the Load on deptt X, Y and Z over the next 4 weeks. Deptt. Product A Product B Product C X 0.20 hr 0.005 hr 0.10 hr Y 0.08 hr 0.15 hr 0.20 hr Z 0.11 hr 0.08 hr 0.05 hr

- 24. ï A deptt. Works on 8 hours shift , 250 days a year and has the usage data of a machine, as given below. Determine the number of Machines required. ï Product Annual demand Std. Time (hrs) X 300 4.0 Y 400 6.0 Z 500 3.0