Air compressor

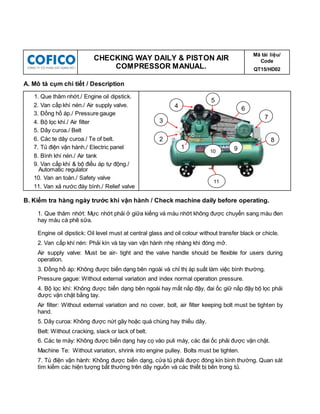

- 1. CHECKING WAY DAILY & PISTON AIR COMPRESSOR MANUAL. M├Ż t├Āi liß╗ću/ Code QT15/HD02 A. M├┤ tß║Ż cß╗źm chi tiß║┐t / Description 1. Que th─ām nhß╗øt./ Engine oil dipstick. 2. Van cß║źp kh├Ł n├®n./ Air supply valve. 3. ─Éß╗ōng hß╗ō ├Īp./ Pressure gauge 4. Bß╗Ö lß╗Źc kh├Ł./ Air filter 5. D├óy curoa./ Belt 6. C├Īc te d├óy curoa./ Te of belt. 7. Tß╗¦ ─æiß╗ćn vß║Łn h├Ānh./ Electric panel 8. B├¼nh kh├Ł n├®n./ Air tank 9. Van cß║źp kh├Ł & bß╗Ö ─æiß╗üu ├Īp tß╗▒ ─æß╗Öng./ Automatic regulator 10. Van an to├Ān./ Safety valve 11. Van xß║Ż nŲ░ß╗øc ─æ├Īy b├¼nh./ Relief valve B. Kiß╗ām tra h├Āng ng├Āy trŲ░ß╗øc khi vß║Łn h├Ānh / Check machine daily before operating. 1. Que th─ām nhß╗øt: Mß╗▒c nhß╗øt phß║Żi ß╗¤ giß╗»a kiß║┐ng v├Ā m├Āu nhß╗øt kh├┤ng ─æŲ░ß╗Żc chuyß╗ān sang m├Āu ─æen hay m├Āu c├Ā ph├¬ sß╗»a. Engine oil dipstick: Oil level must at central glass and oil colour without transfer black or chicle. 2. Van cß║źp kh├Ł n├®n: Phß║Żi k├Łn v├Ā tay van vß║Łn h├Ānh nhß║╣ nh├Āng khi ─æ├│ng mß╗¤. Air supply valve: Must be air- tight and the valve handle should be flexible for users during operation. 3. ─Éß╗ōng hß╗ō ├Īp: Kh├┤ng ─æŲ░ß╗Żc biß║┐n dß║Īng b├¬n ngo├Āi v├Ā chß╗ē thß╗ŗ ├Īp suß║źt l├Ām viß╗ćc b├¼nh thŲ░ß╗Øng. Pressure gague: Without external variation and index normal operation pressure. 4. Bß╗Ö lß╗Źc kh├Ł: Kh├┤ng ─æŲ░ß╗Żc biß║┐n dß║Īng b├¬n ngo├Āi hay mß║źt nß║»p ─æß║Ły, ─æai ß╗æc giß╗» nß║»p ─æß║Ły bß╗Ö lß╗Źc phß║Żi ─æŲ░ß╗Żc vß║Ęn chß║Ęt bß║▒ng tay. Air filter: Without external variation and no cover, bolt, air filter keeping bolt must be tighten by hand. 5. D├óy curoa: Kh├┤ng ─æŲ░ß╗Żc nß╗®t g├Ży hoß║Ęc qu├Ī ch├╣ng hay thiß║┐u d├óy. Belt: Without cracking, slack or lack of belt. 6. C├Īc te m├Īy: Kh├┤ng ─æŲ░ß╗Żc biß║┐n dß║Īng hay cß╗Ź v├Āo puli m├Īy, c├Īc ─æai ß╗æc phß║Żi ─æŲ░ß╗Żc vß║Ęn chß║Ęt. Machine Te: Without variation, shrink into engine pulley. Bolts must be tighten. 7. Tß╗¦ ─æiß╗ćn vß║Łn h├Ānh: Kh├┤ng ─æŲ░ß╗Żc biß║┐n dß║Īng, cß╗Ła tß╗¦ phß║Żi ─æŲ░ß╗Żc ─æ├│ng k├Łn b├¼nh thŲ░ß╗Øng. Quan s├Īt t├¼m kiß║┐m c├Īc hiß╗ćn tŲ░ß╗Żng bß║źt thŲ░ß╗Øng tr├¬n d├óy nguß╗ōn v├Ā c├Īc thiß║┐t bß╗ŗ b├¬n trong tß╗¦. 11 7 6 3 2 5 1 4 8 910

- 2. Electric panel: Without variation, normal tight-closing panel door. Observe to find changeable phenomenon on power wire and component in electric panle. 8. B├¼nh kh├Ł n├®n: T├¼nh trß║Īng b├¼nh thŲ░ß╗Øng kh├┤ng biß║┐n dß║Īng hay bß║źt cß╗® r├▓ rß╗ē n├Āo. Air tank: without variation or any leak. 9. Van cß║źp kh├Ł & bß╗Ö ─æiß╗üu ├Īp tß╗▒ ─æß╗Öng: Tay van vß║Łn h├Ānh nhß║╣ nh├Āng v├Ā ß╗¤ vß╗ŗ tr├Ł mß╗¤ khi vß║Łn h├Ānh. Kiß╗ām tra t├¼nh trß║Īng l├Ām viß╗ćc cß╗¦a bß╗Ö ─æiß╗üu ├Īp trŲ░ß╗øc khi vß║Łn h├Ānh. Automatic regulator: The light operating handel and at opening place while operating. 10. Van an to├Ān: K├®o van an to├Ān xß║Ż kh├Ł ─æß╗ā kiß╗ām tra t├¼nh trß║Īng hoß║Īt ─æß╗Öng. Safety valve: check operating state by vale opening to let out air. 11. Van xß║Ż nŲ░ß╗øc ─æ├Īy b├¼nh: Phß║Żi k├Łn v├Ā tay van vß║Łn h├Ānh nhß║╣ nh├Āng khi ─æ├│ng mß╗¤. Thß╗▒c hiß╗ćn viß╗ćc xß║Ż nŲ░ß╗øc ngŲ░ng tß╗ź h├Āng ng├Āy trŲ░ß╗øc khi vß║Łn h├Ānh. Relief valve: Must be tighten and tight operating handle while using. Carry out condensate relief daily before operating. 12. Kh├┤ng vß║Łn h├Ānh m├Īy n├®n nß║┐u b├¼nh chß╗®a kh├Ł ─æ├Ż hß║┐t hß║Īn kiß╗ām ─æß╗ŗnh. Without air compressor operating while expiring inspection of the air tank. ’ā░ Sau khi kiß╗ām tra nß║┐u c├│ ph├Īt hiß╗ćn bß║źt thŲ░ß╗Øng, phß║Żi dß╗½ng vß║Łn h├Ānh m├Īy v├Ā b├Īo c├Īo cho cß║źp quß║Żn l├Į. ’ā░ After inspecting. The discovered changeable state must be stop machine operating and report to management. C. Vß║Łn h├Ānh m├Īy / Manual 1. Kh├│a van cß║źp kh├Ł n├®n tr├¬n b├¼nh, kiß╗ām tra van cß║źp kh├Ł cho bß╗Ö ─æiß╗üu ├Īp ß╗¤ vß╗ŗ tr├Ł mß╗¤. Lock valve on tank, check valve for regulator at opening place. 2. Khß╗¤i ─æß╗Öng m├Īy bß║▒ng CB hay n├║t On/Off v├Ā ─æß╗Żi m├Īy ─æß║Īt ├Īp suß║źt l├Ām viß╗ćc cao nhß║źt. Start machine by CB or ON/ Off botton and to reach peak working pressure. 3. Mß╗¤ van cß║źp kh├Ł tß╗½ tß╗½ v├Āo hß╗ć thß╗æng hay ß╗æng dß║½n v├Ā bß║»t ─æß║¦u vß║Łn h├Ānh. Open valve to air into system or duck and operating start. 4. Khi kh├┤ng c├▓n nhu cß║¦u sß╗Ł dß╗źng kh├│a van cß║źp kh├Ł, tß║»t m├Īy v├Ā c├║p CB cß║»t ─æiß╗ćn nguß╗ōn. Unless using demand must lock valve, stop machine and isolate CB, power cut. Trong qu├Ī tr├¼nh vß║Łn h├Ānh, lß║Łp tß╗®c dß╗½ng m├Īy khi ph├Īt hiß╗ćn c├Īc hiß╗ćn tŲ░ß╗Żng bß║źt thŲ░ß╗Øng hay tiß║┐ng ß╗ōn lß║Ī v├Ā th├┤ng b├Īo cho cß║źp quß║Żn l├Į./ On operating process, stop immediately machine while discovering changeable state or strange noise and report to management.