Alaa Mohamed CV

0 likes27 views

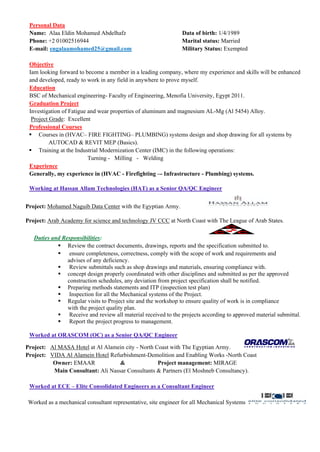

Alaa Eldin Mohamed Abdelhafz is looking for a position that allows him to enhance his experience and skills. He has a BSC in Mechanical Engineering from Menofia University and professional experience in HVAC, firefighting, infrastructure and plumbing systems. His previous roles include working as a Senior QA/QC Engineer on data center and hotel projects and as a Consultant and Site Engineer on various industrial projects. He is skilled in AutoCAD, Revit MEP and has experience in production engineering.

1 of 2

Download to read offline

Recommended

hikal CV June 2016

hikal CV June 2016Ahmed Hikal

Ěý

Ahmed Hikal is a senior mechanical engineer with 14 years of experience in project management for mechanical systems in a wide range of construction projects. He has worked on projects in Egypt, Qatar, and Saudi Arabia. His responsibilities include studying technical drawings, supervising shop drawings, coordinating between teams, reviewing materials, and ensuring quality and compliance with codes and standards. He received a B.Sc. in Mechanical Engineering from Zagazig University in Egypt and is fluent in Arabic and English.aaa

aaaAmr elhoseny

Ěý

Amr Khaled Elhoseny is a mechanical engineer from Egypt seeking a challenging position in engineering. He has a B.Sc. in mechanical power engineering from Cairo University and experience as a QA/QC and site engineer. His responsibilities have included inspections, monitoring mechanical works, and ensuring quality standards. He is proficient in AutoCAD, Matlab, and HVAC systems and software.-04,016-CURRICULUM VITA-Engسيرة ذاتية معتمدة

-04,016-CURRICULUM VITA-Engسيرة ذاتية معتمدةMohammad Ehsan

Ěý

Mohammed Ali Ehsan is an electrical engineer from Jordan with over 25 years of experience in Saudi Arabia. He has a BSc in Electrical Engineering and has held several leadership roles managing electrical, HVAC, and maintenance departments for various construction projects. His experience includes implementing electrical and mechanical systems for universities, residential buildings, factories, and a royal palace in Saudi Arabia.Professional resume

Professional resumeayman adawy

Ěý

Ayman Sayed Adawy is seeking a challenging career in construction where he can utilize his academic background and experience. He has over 10 years of experience in construction projects including roles as a procurement engineer, site manager, project engineer, and site engineer. He holds a Master's degree in mechanical engineering from Ain Shams University and is proficient in various computer programs, construction management software, and has technical certifications.Ahmed Zahran C.V

Ahmed Zahran C.VAhmed Zahran

Ěý

Eng. Ahmed Zahran has over 11 years of experience in electrical engineering in Egypt, Saudi Arabia, and Morocco. He has worked on a variety of projects including hospitals, hotels, office buildings, and infrastructure. His roles have included design, construction supervision, quality control, and maintenance engineering. He has a Bachelor's degree in Electrical Power and Machines Engineering and professional affiliations.Eng Jihad Amro C.V-2015 new

Eng Jihad Amro C.V-2015 newJihad Amro

Ěý

This document contains the resume of Jihad Mahmoud Mohammed Amro. It details his objective, education, practical experiences, training courses and skills. For practical experiences, it lists his roles as MEP Coordinator and Technical Engineer at Thermo Saudi L.L.C. and as a Mechanical Project Engineer for several projects in Saudi Arabia and the UAE. It also provides details on 15 famous projects he worked on as an HVAC Design Engineer at ELMACS Co. in Abu Dhabi.CV_Alaa Eldin_Mech

CV_Alaa Eldin_MechAlaa El Deen

Ěý

The document is a resume for Alaa Eldin Mohammed Hosni, an Egyptian mechanical engineer seeking a new position. It outlines his education, including a degree from Helwan University in mechanical power, and work experience on various mechanical engineering projects in Egypt, including roles as both a site engineer and office engineer. His responsibilities have involved mechanical systems design, installation, and commissioning of HVAC, firefighting, and plumbing systems. He also lists relevant coursework, skills, and computer proficiencies.Mechatronics Engineer (2015) (1)

Mechatronics Engineer (2015) (1)ramy samhoud

Ěý

This document is a CV for Ramy Saleh Ahmed Samhoud, a Saudi national. It outlines his personal information, objective of seeking a project management role in mechanical engineering, skills in mechanical engineering principles and tools as well as PLC and SCADA systems, and communication skills. It details his work experience from 2012 to present as a building utility inspector for ARAMCO, and other previous roles. It also provides information on his 2011 bachelor's degree in mechatronics engineering, 2005 diploma in computer programming and technology, university training in PLC and SCADA systems, and proficiency in English. Contact information is included at the end.Resume_Justin

Resume_JustinJustin N Lopez

Ěý

Justin N. Lopez is a senior facilities management engineer with over 16 years of experience in construction and facilities management in the UAE, Bahrain, India, and the Kingdom of Saudi Arabia. He has extensive experience managing MEP systems, facilities operations, and health and safety procedures. His roles have included overseeing teams, budgets, and client relationships. He holds qualifications in building automation, asset management, CAFM systems, tendering, and electrical and mechanical maintenance.Sanoop CV 2016

Sanoop CV 2016Sanoop Ashraf

Ěý

Sanoop Ashraf is a mechanical engineer with over 6 years of experience in installation, supervision, testing, and commissioning of HVAC, plumbing, drainage, and fire fighting systems. He is currently a Site Mechanical Engineer at Elmech Electromechanical Works LLC in Dubai. Previously he has worked on projects in Qatar and India. He is seeking a new position as a Mechanical Engineer or Inspector where he can utilize his skills in project management, planning, quality control, and team leadership.Amr Desoky

Amr Desokymuhammed deusoky

Ěý

Muhammed Deusoky is seeking a position in Mechanical Engineering. He has a Bachelor's degree in Mechanical Power Engineering and over 8 years of experience in mechanical construction including HVAC, ventilation and plumbing. His experience includes consulting, installation of HVAC equipment, freezing room design, and installation of central air conditioning and chilled water units. He has worked as a Mechanical Consulting Engineer and Mechanical Site Engineer in Egypt.F.M.Camus (CV 2016)

F.M.Camus (CV 2016)FERNANDO CAMUS

Ěý

This document provides a summary of qualifications and experience for Fernando M. Camus, an electrical engineer with over 20 years of experience in testing, commissioning, and project management of electrical systems and installations in Qatar, the Philippines, and the UAE. He has managed electrical commissioning projects for numerous high-profile buildings and infrastructure projects such as airports, hospitals, and stadiums. Camus holds a Bachelor's degree in Electrical Engineering and is proficient in AutoCAD.CV mohamed

CV mohamedMohamed EL Saadani, PMP

Ěý

This document is a curriculum vitae for Mohamed Mahmud Elsaadani. It summarizes his professional experience and qualifications. He has over 20 years of experience managing construction projects in Egypt and Qatar, including hotels, resorts, roads, and other major developments. He is a certified Project Management Professional (PMP) with the Project Management Institute and holds an MBA degree. His experience includes planning, scheduling, budgeting, and overseeing all aspects of large construction projects from start to completion.CV_WALEED

CV_WALEEDwaleed thabet

Ěý

Waleed Thabet Mohamed is an Egyptian project electrical engineer with over 11 years of experience in MEP construction in the UAE. He holds a B.S. in Electrical Power & Machine Engineering and is currently working as a Project Electrical Engineer for United Masters Electromechanical Company in Dubai. His objective is to utilize his analytical and leadership skills while furthering his career stability.OMRAN CV

OMRAN CVOmran Ahmed Omran Ahmed

Ěý

Omran Ahmed Omran is seeking a challenging opportunity as a MEP Project Manager, having over 20 years of experience managing MEP projects in the UAE and Egypt. He has managed numerous hospital, hotel, commercial and residential building projects with budgets over $100 million. Omran is proficient in coordinating HVAC, fire protection, plumbing, BMS and electrical systems and ensuring projects are delivered on time, on budget and meeting quality standards. He aims to achieve success for his employers and clients.Emad Medhat Resume

Emad Medhat ResumeEmad Ghobrial

Ěý

Emad Mounier is seeking a position that utilizes his engineering background and interpersonal skills. He has a Bachelor's degree in Mechanical Power Engineering from Zagazig University in Egypt. His work experience includes positions in production, maintenance, and as a site mechanical engineer for fire fighting and plumbing systems where he led teams and coordinated projects. He has skills in AutoCAD, Microsoft Office, and problem solving.Mamoud Maani_CV

Mamoud Maani_CVMahmoud Ma'ani

Ěý

Mahmoud Ma’ani is a mechanical engineer from Jordan with over 4 years of experience in construction projects in Dubai. He has worked as a mechanical engineer and site engineer on projects involving HVAC, plumbing, and mechanical systems design and installation. His experience includes working on projects such as villas, housing complexes, and commercial buildings. He is proficient in AutoCAD, Primavera, and Microsoft Office applications. He is looking for new opportunities as a mechanical engineer in Dubai.Eng.ahmed_Yousef CV

Eng.ahmed_Yousef CVahmed yousef

Ěý

Ahmed Mohammed Yousef Baghdadi is an Egyptian civil engineer with over 15 years of experience in project management and technical engineering roles in Saudi Arabia and Egypt. He holds a Bachelor's degree in Civil Engineering and has managed projects such as tower buildings, fire stations, schools, and housing developments with budgets up to $50 million. His skills include construction planning, scheduling, cost estimation, quality and safety coordination, and issue resolution. He is seeking new project management opportunities.Baher mohamed ali ahmed resume ###

Baher mohamed ali ahmed resume ###Baher Elziady

Ěý

This document contains a summary of Baher Elziady's experience as a mechanical engineer, including his education and skills. It lists his previous roles as a senior mechanical engineer, mechanical project manager, senior mechanical engineer, project engineer, site engineer mechanical, mechanical engineer, and junior engineer. It also lists his skills in areas such as HVAC, AutoCAD, Revit, and languages including English. Ahmed_Mohammed

Ahmed_Mohammedahmed ali

Ěý

Ahmed Mohammed Mahmoud Ali is an Egyptian electrical engineer seeking a challenging position. He has over 7 years of experience in electrical engineering projects including residential compounds, commercial buildings, and infrastructure works. He has worked in technical office, site, and tender roles managing projects and teams. His education includes a bachelor's degree in electrical power and machinery from Helwan University.ahmed amer

ahmed amerAhmed abdaljawad

Ěý

1) Ahmed Amer is an Egyptian electrical engineer with 15 years of experience managing electrical teams and projects in Egypt, Saudi Arabia, and internationally.

2) He has a BSc in electrical engineering from Cairo University and is seeking a position utilizing his experience in electrical design, project management, and maintenance.

3) His background includes overseeing electrical work for several large-scale projects in Saudi Arabia and Egypt, such as the Prophet's Mosque expansion and Mubarak TV studio complex.Mechanical Engineer - Plumbing and Fire Fighting

Mechanical Engineer - Plumbing and Fire FightingHazem Mahdy

Ěý

This document provides a resume for Hazem Amr Mohamed, a mechanical engineer with over 6 years of experience in mechanical engineering design for fire protection and plumbing systems. It details his work history with ECG Engineering Consultants Group where he has served as a senior mechanical engineer on various projects including hospitals, warehouses, hotels, and government buildings. It also lists his education, technical skills, computer skills, and language abilities.isalmrashed cv

isalmrashed cvIslam Rashed

Ěý

Islam Abdelhaliem Ali Rashed is a highly motivated and goal-oriented professional with over 10 years of experience in instrumentation and control engineering. He has worked on projects in Egypt for clients such as ENI, BP, and PHPC. His experience includes commissioning, maintenance, and troubleshooting of instrumentation systems for LNG, gas, and industrial plants. He has strong technical skills in instrumentation design, calibration, loop checking, and preventative maintenance. He is proficient in MAXIMO and holds certifications in measurement and control fundamentals, networking, and safety training.MOHAMMED SAMEER.docx

MOHAMMED SAMEER.docxSadathAhmed2

Ěý

This document provides a summary of the qualifications and experience of Mohammed Sameer, a mechanical engineer with experience in HVAC system design, installation, and commissioning for residential and commercial projects. He has over 17 months of experience in HVAC site execution. His roles have included system design using HVAC software, procurement, coordinating installation, ensuring quality, and assisting with commissioning and handover. He holds a BTech in Mechanical Engineering and diploma in Mechanical Engineering and is proficient in AutoCAD, MS Office, and HVAC design software.Khaled Mahfouz

Khaled MahfouzKhaled Mahfouz

Ěý

This document provides a summary of Khaled Mahfouz Abd ALLAH Abd Al kader's career objective, education, and work experience. His objective is to seek a challenging opportunity in mechanical engineering where he can utilize and develop his studies, experience, and skills. He has a Bachelor's degree in Mechanical Power Engineering from Benha University in Egypt. His work experience includes roles as a Quality Assurance/Quality Control Engineer for GEA GRADE Refrigeration in the UAE and as a Mechanical Quality Control Engineer for Orascom Construction & Industries in Egypt.Veronica Atef Ramzy

Veronica Atef RamzyVeronica Tawfik

Ěý

Veronica Atef Ramzy Tawfik is an Egyptian mechanical engineer with over 10 years of experience in designing HVAC, plumbing, and firefighting systems. She is currently a Senior Technical Office Mechanical Engineer at Orascom Construction Industries, where she reviews designs and provides technical support for the Egyptian Army Conference Hall project. Previously, she worked as a Senior and Junior Technical Office Mechanical Engineer at URS/CONTRACK International Inc., designing mechanical systems for Egyptian Air Force bases. She holds a B.Sc. in Mechanical Engineering from Ain Shams University and has extensive training in areas like HVAC design, plumbing, and AutoCAD.Mohamed Ahmed Zeyada, Dec. 2015

Mohamed Ahmed Zeyada, Dec. 2015???? ?????

Ěý

Mohamed Ahmed Zeyada has over 15 years of experience in project management and engineering roles at ABB Power Systems & Automation Technologies. He has successfully led numerous electrical and instrumentation projects in Egypt for industries such as oil and gas, mining, and utilities. His roles have included project manager, project engineering leader, and site construction leader. He has extensive experience developing project plans, schedules, specifications, and managing project execution according to safety, quality and budget targets. He holds a B.Sc. in Electrical Engineering and has received training in project management, leadership, safety and other relevant areas from ABB and other organizations.Instrument and Control Engineer Anas

Instrument and Control Engineer AnasAnas Bin Ahmad

Ěý

Anas Bin Ahmad is an experienced Instrumentation and Control Engineer with over 9 years of experience in the field. He has strong experience in all areas of instrumentation and control engineering including understanding P&IDs, developing I/O lists, control system architecture, loop diagrams, and more. He is proficient in various engineering standards and has worked on projects in Pakistan and the UAE. Anas seeks to utilize his skills and experience to contribute to successful project completion.Ahmed abd elazim c.v

Ahmed abd elazim c.vAhmed Abd elazim

Ěý

This document contains a resume for Ahmed Abd Elazim Abd Elfatah. It includes his contact information, objective of seeking a mechanical engineering position, education credentials including a bachelor's degree in mechanical engineering, work experience in several mechanical engineering and project management roles in Egypt, skills and qualifications, and hobbies. His most recent role is as a Lead Mechanical Engineer for a power plant project in Egypt.Saeed Fadl CV

Saeed Fadl CVsaeed981

Ěý

Saeed Fadl is a Syrian project engineer and mechanical site inspector with 13 years of experience in building, district cooling plant, ETS room, and pipe network construction projects in Dubai. He has worked as a project engineer, coordinator, and mechanical site inspector at Emirates Central Cooling Company, supervising the installation of pipe networks, energy transfer stations, and temporary plants. He is proficient in English and familiar with MS Office and international codes and standards.More Related Content

What's hot (20)

Resume_Justin

Resume_JustinJustin N Lopez

Ěý

Justin N. Lopez is a senior facilities management engineer with over 16 years of experience in construction and facilities management in the UAE, Bahrain, India, and the Kingdom of Saudi Arabia. He has extensive experience managing MEP systems, facilities operations, and health and safety procedures. His roles have included overseeing teams, budgets, and client relationships. He holds qualifications in building automation, asset management, CAFM systems, tendering, and electrical and mechanical maintenance.Sanoop CV 2016

Sanoop CV 2016Sanoop Ashraf

Ěý

Sanoop Ashraf is a mechanical engineer with over 6 years of experience in installation, supervision, testing, and commissioning of HVAC, plumbing, drainage, and fire fighting systems. He is currently a Site Mechanical Engineer at Elmech Electromechanical Works LLC in Dubai. Previously he has worked on projects in Qatar and India. He is seeking a new position as a Mechanical Engineer or Inspector where he can utilize his skills in project management, planning, quality control, and team leadership.Amr Desoky

Amr Desokymuhammed deusoky

Ěý

Muhammed Deusoky is seeking a position in Mechanical Engineering. He has a Bachelor's degree in Mechanical Power Engineering and over 8 years of experience in mechanical construction including HVAC, ventilation and plumbing. His experience includes consulting, installation of HVAC equipment, freezing room design, and installation of central air conditioning and chilled water units. He has worked as a Mechanical Consulting Engineer and Mechanical Site Engineer in Egypt.F.M.Camus (CV 2016)

F.M.Camus (CV 2016)FERNANDO CAMUS

Ěý

This document provides a summary of qualifications and experience for Fernando M. Camus, an electrical engineer with over 20 years of experience in testing, commissioning, and project management of electrical systems and installations in Qatar, the Philippines, and the UAE. He has managed electrical commissioning projects for numerous high-profile buildings and infrastructure projects such as airports, hospitals, and stadiums. Camus holds a Bachelor's degree in Electrical Engineering and is proficient in AutoCAD.CV mohamed

CV mohamedMohamed EL Saadani, PMP

Ěý

This document is a curriculum vitae for Mohamed Mahmud Elsaadani. It summarizes his professional experience and qualifications. He has over 20 years of experience managing construction projects in Egypt and Qatar, including hotels, resorts, roads, and other major developments. He is a certified Project Management Professional (PMP) with the Project Management Institute and holds an MBA degree. His experience includes planning, scheduling, budgeting, and overseeing all aspects of large construction projects from start to completion.CV_WALEED

CV_WALEEDwaleed thabet

Ěý

Waleed Thabet Mohamed is an Egyptian project electrical engineer with over 11 years of experience in MEP construction in the UAE. He holds a B.S. in Electrical Power & Machine Engineering and is currently working as a Project Electrical Engineer for United Masters Electromechanical Company in Dubai. His objective is to utilize his analytical and leadership skills while furthering his career stability.OMRAN CV

OMRAN CVOmran Ahmed Omran Ahmed

Ěý

Omran Ahmed Omran is seeking a challenging opportunity as a MEP Project Manager, having over 20 years of experience managing MEP projects in the UAE and Egypt. He has managed numerous hospital, hotel, commercial and residential building projects with budgets over $100 million. Omran is proficient in coordinating HVAC, fire protection, plumbing, BMS and electrical systems and ensuring projects are delivered on time, on budget and meeting quality standards. He aims to achieve success for his employers and clients.Emad Medhat Resume

Emad Medhat ResumeEmad Ghobrial

Ěý

Emad Mounier is seeking a position that utilizes his engineering background and interpersonal skills. He has a Bachelor's degree in Mechanical Power Engineering from Zagazig University in Egypt. His work experience includes positions in production, maintenance, and as a site mechanical engineer for fire fighting and plumbing systems where he led teams and coordinated projects. He has skills in AutoCAD, Microsoft Office, and problem solving.Mamoud Maani_CV

Mamoud Maani_CVMahmoud Ma'ani

Ěý

Mahmoud Ma’ani is a mechanical engineer from Jordan with over 4 years of experience in construction projects in Dubai. He has worked as a mechanical engineer and site engineer on projects involving HVAC, plumbing, and mechanical systems design and installation. His experience includes working on projects such as villas, housing complexes, and commercial buildings. He is proficient in AutoCAD, Primavera, and Microsoft Office applications. He is looking for new opportunities as a mechanical engineer in Dubai.Eng.ahmed_Yousef CV

Eng.ahmed_Yousef CVahmed yousef

Ěý

Ahmed Mohammed Yousef Baghdadi is an Egyptian civil engineer with over 15 years of experience in project management and technical engineering roles in Saudi Arabia and Egypt. He holds a Bachelor's degree in Civil Engineering and has managed projects such as tower buildings, fire stations, schools, and housing developments with budgets up to $50 million. His skills include construction planning, scheduling, cost estimation, quality and safety coordination, and issue resolution. He is seeking new project management opportunities.Baher mohamed ali ahmed resume ###

Baher mohamed ali ahmed resume ###Baher Elziady

Ěý

This document contains a summary of Baher Elziady's experience as a mechanical engineer, including his education and skills. It lists his previous roles as a senior mechanical engineer, mechanical project manager, senior mechanical engineer, project engineer, site engineer mechanical, mechanical engineer, and junior engineer. It also lists his skills in areas such as HVAC, AutoCAD, Revit, and languages including English. Ahmed_Mohammed

Ahmed_Mohammedahmed ali

Ěý

Ahmed Mohammed Mahmoud Ali is an Egyptian electrical engineer seeking a challenging position. He has over 7 years of experience in electrical engineering projects including residential compounds, commercial buildings, and infrastructure works. He has worked in technical office, site, and tender roles managing projects and teams. His education includes a bachelor's degree in electrical power and machinery from Helwan University.ahmed amer

ahmed amerAhmed abdaljawad

Ěý

1) Ahmed Amer is an Egyptian electrical engineer with 15 years of experience managing electrical teams and projects in Egypt, Saudi Arabia, and internationally.

2) He has a BSc in electrical engineering from Cairo University and is seeking a position utilizing his experience in electrical design, project management, and maintenance.

3) His background includes overseeing electrical work for several large-scale projects in Saudi Arabia and Egypt, such as the Prophet's Mosque expansion and Mubarak TV studio complex.Mechanical Engineer - Plumbing and Fire Fighting

Mechanical Engineer - Plumbing and Fire FightingHazem Mahdy

Ěý

This document provides a resume for Hazem Amr Mohamed, a mechanical engineer with over 6 years of experience in mechanical engineering design for fire protection and plumbing systems. It details his work history with ECG Engineering Consultants Group where he has served as a senior mechanical engineer on various projects including hospitals, warehouses, hotels, and government buildings. It also lists his education, technical skills, computer skills, and language abilities.isalmrashed cv

isalmrashed cvIslam Rashed

Ěý

Islam Abdelhaliem Ali Rashed is a highly motivated and goal-oriented professional with over 10 years of experience in instrumentation and control engineering. He has worked on projects in Egypt for clients such as ENI, BP, and PHPC. His experience includes commissioning, maintenance, and troubleshooting of instrumentation systems for LNG, gas, and industrial plants. He has strong technical skills in instrumentation design, calibration, loop checking, and preventative maintenance. He is proficient in MAXIMO and holds certifications in measurement and control fundamentals, networking, and safety training.MOHAMMED SAMEER.docx

MOHAMMED SAMEER.docxSadathAhmed2

Ěý

This document provides a summary of the qualifications and experience of Mohammed Sameer, a mechanical engineer with experience in HVAC system design, installation, and commissioning for residential and commercial projects. He has over 17 months of experience in HVAC site execution. His roles have included system design using HVAC software, procurement, coordinating installation, ensuring quality, and assisting with commissioning and handover. He holds a BTech in Mechanical Engineering and diploma in Mechanical Engineering and is proficient in AutoCAD, MS Office, and HVAC design software.Khaled Mahfouz

Khaled MahfouzKhaled Mahfouz

Ěý

This document provides a summary of Khaled Mahfouz Abd ALLAH Abd Al kader's career objective, education, and work experience. His objective is to seek a challenging opportunity in mechanical engineering where he can utilize and develop his studies, experience, and skills. He has a Bachelor's degree in Mechanical Power Engineering from Benha University in Egypt. His work experience includes roles as a Quality Assurance/Quality Control Engineer for GEA GRADE Refrigeration in the UAE and as a Mechanical Quality Control Engineer for Orascom Construction & Industries in Egypt.Veronica Atef Ramzy

Veronica Atef RamzyVeronica Tawfik

Ěý

Veronica Atef Ramzy Tawfik is an Egyptian mechanical engineer with over 10 years of experience in designing HVAC, plumbing, and firefighting systems. She is currently a Senior Technical Office Mechanical Engineer at Orascom Construction Industries, where she reviews designs and provides technical support for the Egyptian Army Conference Hall project. Previously, she worked as a Senior and Junior Technical Office Mechanical Engineer at URS/CONTRACK International Inc., designing mechanical systems for Egyptian Air Force bases. She holds a B.Sc. in Mechanical Engineering from Ain Shams University and has extensive training in areas like HVAC design, plumbing, and AutoCAD.Mohamed Ahmed Zeyada, Dec. 2015

Mohamed Ahmed Zeyada, Dec. 2015???? ?????

Ěý

Mohamed Ahmed Zeyada has over 15 years of experience in project management and engineering roles at ABB Power Systems & Automation Technologies. He has successfully led numerous electrical and instrumentation projects in Egypt for industries such as oil and gas, mining, and utilities. His roles have included project manager, project engineering leader, and site construction leader. He has extensive experience developing project plans, schedules, specifications, and managing project execution according to safety, quality and budget targets. He holds a B.Sc. in Electrical Engineering and has received training in project management, leadership, safety and other relevant areas from ABB and other organizations.Instrument and Control Engineer Anas

Instrument and Control Engineer AnasAnas Bin Ahmad

Ěý

Anas Bin Ahmad is an experienced Instrumentation and Control Engineer with over 9 years of experience in the field. He has strong experience in all areas of instrumentation and control engineering including understanding P&IDs, developing I/O lists, control system architecture, loop diagrams, and more. He is proficient in various engineering standards and has worked on projects in Pakistan and the UAE. Anas seeks to utilize his skills and experience to contribute to successful project completion.Similar to Alaa Mohamed CV (20)

Ahmed abd elazim c.v

Ahmed abd elazim c.vAhmed Abd elazim

Ěý

This document contains a resume for Ahmed Abd Elazim Abd Elfatah. It includes his contact information, objective of seeking a mechanical engineering position, education credentials including a bachelor's degree in mechanical engineering, work experience in several mechanical engineering and project management roles in Egypt, skills and qualifications, and hobbies. His most recent role is as a Lead Mechanical Engineer for a power plant project in Egypt.Saeed Fadl CV

Saeed Fadl CVsaeed981

Ěý

Saeed Fadl is a Syrian project engineer and mechanical site inspector with 13 years of experience in building, district cooling plant, ETS room, and pipe network construction projects in Dubai. He has worked as a project engineer, coordinator, and mechanical site inspector at Emirates Central Cooling Company, supervising the installation of pipe networks, energy transfer stations, and temporary plants. He is proficient in English and familiar with MS Office and international codes and standards.Saeed Fadl CV

Saeed Fadl CVsaeed981

Ěý

Saeed Fadl is a Syrian project engineer and mechanical site inspector with 13 years of experience in building, district cooling plant, ETS room, and pipe network construction projects in Dubai and Abu Dhabi. He has worked as a project engineer, coordinator, and mechanical site inspector for Emirates Central Cooling Company on numerous large projects. Currently based in Dubai, he holds an mechanical engineering degree from Aleppo University and is proficient in Arabic, English, and MS Office software.Senior MEP Engineer_Hossam Abdel Fattah TAG ELDIN

Senior MEP Engineer_Hossam Abdel Fattah TAG ELDINHossam Fattah

Ěý

Hossam is applying for a Senior MEP engineering position and has over 14 years of experience in MEP installations for large infrastructure projects. He has extensive experience managing HVAC, electrical, plumbing and other systems. Hossam is looking for an interview to discuss how he can help with the company's projects using his strong background in electromechanical systems.Ahmed El- Kholy CV

Ahmed El- Kholy CVAHMED EL-KHOLY

Ěý

Ahmed El-Kholy is a mechanical/piping engineer and commissioning specialist with over 9 years of experience in oil and gas, power plants, and other process industries. He has extensive experience in piping design, construction, commissioning, and project management. His resume lists responsibilities such as piping design, construction supervision, commissioning, training, and ensuring projects meet quality, schedule, and safety standards. He is proficient in AutoCAD, PDMS, stress analysis software, and other engineering tools.Abo-Eldardaa_CV_2015 & Duties

Abo-Eldardaa_CV_2015 & Dutiesabo.eldardaa mahmoud

Ěý

AboEldardaa MohamedAhmedMahmoud has over 28 years of experience as a civil engineer and project manager. He holds a B.Sc. in Civil Engineering from Assiut University in Egypt and a graduate diploma in structural engineering from Cairo University. Throughout his career, he has worked on numerous construction projects in Egypt, Kuwait, and Saudi Arabia, taking on roles such as senior planning engineer, construction management manager, site engineer, resident engineer, and project manager. His responsibilities have included project scheduling, monitoring progress, managing project teams, and ensuring quality standards.Copy of Eng.OMARA CV

Copy of Eng.OMARA CVMohamed Omara

Ěý

This curriculum vitae is for Mohamed Omara Elsayed, an Egyptian national seeking a challenging position where he can apply his academic and professional experience. He has a bachelor's degree in mechanical power engineering from Helwan University and over 10 years of work experience in project engineering, maintenance, and as a technical office engineer. He has skills in AutoCAD, refrigeration, HVAC, management, and languages including English and Arabic.Ahmad fathy cv

Ahmad fathy cvahmed fathy

Ěý

This CV summarizes the qualifications and experience of Ahmad Fathi Mohamed, a Mechanical Engineer from Egypt. He received a Bachelor's degree in Power Mechanics from Helwan University in 2014. His experience includes working as a Technical Office Engineer for Misr Contraco Group from 2015 to present, where his duties include HVAC and firefighting project management and documentation. He also has experience working on hospital, shopping mall, and hotel HVAC system installation projects.Anas Khalifa's CV_JAN.-2017

Anas Khalifa's CV_JAN.-2017Anas Khalifa

Ěý

This document is a resume for AnAs Ahmed Ahmed KhAlifA, a mechanical engineer seeking a position utilizing his education and experience in project management, construction, and MEP engineering. His qualifications include a B.S.C. in mechanical engineering from Alexandria University and over 7 years of experience in Qatar and other countries. He has numerous certifications in areas such as project management, risk management, HVAC design, and safety. His experience includes roles in mechanical engineering, construction, fabrication, installation, testing, and commissioning of MEP and oil and gas projects.Anas Khalifa's CV_JAN.-2017

Anas Khalifa's CV_JAN.-2017Anas Khalifa

Ěý

This document is a resume for AnAs Ahmed Ahmed KhAlifA, a mechanical engineer seeking a position utilizing his education and experience in project engineering, construction, and MEP systems. It lists his qualifications including a B.S. in mechanical engineering, various technical certifications, and over 7 years of experience in mechanical, construction, fabrication, and commissioning of MEP, oil and gas, and other industrial projects in Qatar, Saudi Arabia, Egypt, and the United States.Mariam cv

Mariam cvMariam Atef

Ěý

This document is a resume for Mariam Atef Saleeb, an Egyptian mechanical engineer with over 8 years of experience in project and sales engineering. She holds a Bachelor's degree in Mechanical Engineering from Helwan University, Egypt. Her career experience includes roles as a project and sales engineer and mechanical engineer for The Egyptian company for supplies, where she was responsible for following various projects in oil, gas, marine, and other industries. She also lists relevant skills, education history, and personal details.Asim_Siraj__Mechanical_updated

Asim_Siraj__Mechanical_updatedasim siraj

Ěý

Asim Siraj is a mechanical engineer seeking a position in mechanical engineering. He has over 15 years of experience in HVAC projects in India and the Middle East. His skills include project management, planning, coordination, material management, and commissioning of mechanical systems. He has managed projects such as schools, hotels, and commercial buildings. His qualifications include a Diploma in Mechanical Engineering and a BE degree. He is proficient in English, Hindi, and Arabic.omar CV

omar CVOmar Bou Ghannam

Ěý

Omar Bou Ghannam is a Lebanese Project Engineer with over 15 years of experience in mechanical engineering. He has specialized skills in HVAC engineering, construction project management, and manufacturing process supervision. Currently he works as a Project Engineer for a central air conditioning company in Saudi Arabia, where he is responsible for carrying out HVAC engineering works, coordinating with clients, and managing project budgets and schedules. Previously he held engineering supervisory roles overseeing production operations and quality control.CV(Mechanical maintenance Engineer-project Manager)Alaa Abd ElKader - Last up...

CV(Mechanical maintenance Engineer-project Manager)Alaa Abd ElKader - Last up...Alaa abdelkader

Ěý

This document provides a summary of a maintenance manager's qualifications and experience. The maintenance manager has over 10 years of experience in mechanical maintenance roles in various industries like sugar, food, and oil crushing plants. He is seeking a role to lead the mechanical maintenance function and has experience managing teams of up to 80 personnel. He has a bachelor's degree in mechanical engineering and various technical certifications. His experience includes equipment maintenance, tendering, project management, and overseeing construction activities.Mostafa omar el beh 2015 cv

Mostafa omar el beh 2015 cvMostafa Omar

Ěý

(1) El-Mostafa Mohammed Omar Ahmed Beh is seeking a position in mechanical engineering where he can utilize over 15 years of experience in mechanical and piping projects. (2) He has extensive experience managing piping projects in various industries including oil and gas, petrochemical, and power plants. (3) His responsibilities have included supervision of fabrication, installation, testing, and commissioning of piping systems as well as managing health and safety.Ayman curriculum vitae2

Ayman curriculum vitae2Ayman Hassan Refaie

Ěý

Sr.mechanical engineer have more than 17 years experience in MEP field starting from design up to handing over to client and follow up the maintenance, Able to manage and coordinate all construction activities successful career by working for a ambitious & exciting company.Ayman curriculum vitae

Ayman curriculum vitaeAyman Hassan Refaie

Ěý

Ayman Hassan Refae is an experienced mechanical engineer seeking new opportunities. He has over 20 years of experience managing MEP works on construction projects in Egypt, UAE, and Qatar. His background includes roles as a senior mechanical engineer for the National Authority for Tunnels in Egypt and as a senior electro-mechanical engineer for SYSTRA in Dubai. He is proficient in English and Arabic and has experience with AutoCAD, Microsoft Office, and construction project management software.Ayman curriculum vitae

Ayman curriculum vitaeAyman Hassan Refaie

Ěý

Ayman Hassan Refae is an experienced mechanical engineer seeking new opportunities. He has over 20 years of experience managing MEP works on construction projects in Egypt, UAE, and Qatar. His background includes roles as a senior mechanical engineer, senior electro-mechanical engineer, and mechanical engineer. He is proficient in English and Arabic with skills in AutoCAD, Microsoft Office, and construction project management software.Mohamed Melouk CV - Septmeber 2016 - MEP

Mohamed Melouk CV - Septmeber 2016 - MEPMohamed Melouk

Ěý

Mohamed Magdi Melouk is a mechanical engineer from Egypt with over 5 years of experience in MEP construction and facility management projects in the UAE. He has a B.Sc. in Mechanical Engineering from Alexandria University and is a certified mechanical engineer. His experience includes working as a mechanical engineer and project engineer on residential and commercial projects, supervising installation and ensuring compliance with specifications. Currently he works as a mechanical engineer and inspector for Dorsch Holding on a 162 villa residential complex, overseeing water, drainage, HVAC and fire protection systems.Osama Hussein CV.

Osama Hussein CV.osama hussein

Ěý

This document is the resume of Osama Hussein, an Egyptian electrical engineer with over 12 years of experience working on projects in the cement, waste water, and chemical industries. It provides his personal details, education history, professional experience working for companies like ASEC Automation and CEGELEC, and capabilities like electrical design, commissioning, project management, and working in foreign countries.Recently uploaded (20)

How to Build a Maze Solving Robot Using Arduino

How to Build a Maze Solving Robot Using ArduinoCircuitDigest

Ěý

Learn how to make an Arduino-powered robot that can navigate mazes on its own using IR sensors and "Hand on the wall" algorithm.

This step-by-step guide will show you how to build your own maze-solving robot using Arduino UNO, three IR sensors, and basic components that you can easily find in your local electronics shop.Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...

Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...slayshadow705

Ěý

This presentation provides an in-depth analysis of structural quality control in the KRP 401600 section of the Copper Processing Plant-3 (MOF-3) in Uzbekistan. As a Structural QA/QC Inspector, I have identified critical welding defects, alignment issues, bolting problems, and joint fit-up concerns.

Key topics covered:

✔ Common Structural Defects – Welding porosity, misalignment, bolting errors, and more.

✔ Root Cause Analysis – Understanding why these defects occur.

✔ Corrective & Preventive Actions – Effective solutions to improve quality.

✔ Team Responsibilities – Roles of supervisors, welders, fitters, and QC inspectors.

✔ Inspection & Quality Control Enhancements – Advanced techniques for defect detection.

📌 Applicable Standards: GOST, KMK, SNK – Ensuring compliance with international quality benchmarks.

🚀 This presentation is a must-watch for:

âś… QA/QC Inspectors, Structural Engineers, Welding Inspectors, and Project Managers in the construction & oil & gas industries.

âś… Professionals looking to improve quality control processes in large-scale industrial projects.

📢 Download & share your thoughts! Let's discuss best practices for enhancing structural integrity in industrial projects.

Categories:

Engineering

Construction

Quality Control

Welding Inspection

Project Management

Tags:

#QAQC #StructuralInspection #WeldingDefects #BoltingIssues #ConstructionQuality #Engineering #GOSTStandards #WeldingInspection #QualityControl #ProjectManagement #MOF3 #CopperProcessing #StructuralEngineering #NDT #OilAndGasGauges are a Pump's Best Friend - Troubleshooting and Operations - v.07

Gauges are a Pump's Best Friend - Troubleshooting and Operations - v.07Brian Gongol

Ěý

No reputable doctor would try to conduct a basic physical exam without the help of a stethoscope. That's because the stethoscope is the best tool for gaining a basic "look" inside the key systems of the human body. Gauges perform a similar function for pumping systems, allowing technicians to "see" inside the pump without having to break anything open. Knowing what to do with the information gained takes practice and systemic thinking. This is a primer in how to do that.Industrial Valves, Instruments Products Profile

Industrial Valves, Instruments Products Profilezebcoeng

Ěý

We’re excited to share our product profile, showcasing our expertise in Industrial Valves, Instrumentation, and Hydraulic & Pneumatic Solutions.

We also supply API-approved valves from globally trusted brands, ensuring top-notch quality and internationally certified solutions. Let’s explore valuable business opportunities together!

We specialize in:

• Industrial Valves (Gate, Globe, Ball, Butterfly, Check)

• Instrumentation (Pressure Gauges, Transmitters, Flow Meters)

• Pneumatic Products (Cylinders, Solenoid Valves, Fittings)

As authorized partners of trusted global brands, we deliver high-quality solutions tailored to meet your industrial needs with seamless support.Lecture -3 Cold water supply system.pptx

Lecture -3 Cold water supply system.pptxrabiaatif2

Ěý

The presentation on Cold Water Supply explored the fundamental principles of water distribution in buildings. It covered sources of cold water, including municipal supply, wells, and rainwater harvesting. Key components such as storage tanks, pipes, valves, and pumps were discussed for efficient water delivery. Various distribution systems, including direct and indirect supply methods, were analyzed for residential and commercial applications. The presentation emphasized water quality, pressure regulation, and contamination prevention. Common issues like pipe corrosion, leaks, and pressure drops were addressed along with maintenance strategies. Diagrams and case studies illustrated system layouts and best practices for optimal performance.How Engineering Model Making Brings Designs to Life.pdf

How Engineering Model Making Brings Designs to Life.pdfMaadhu Creatives-Model Making Company

Ěý

This PDF highlights how engineering model making helps turn designs into functional prototypes, aiding in visualization, testing, and refinement. It covers different types of models used in industries like architecture, automotive, and aerospace, emphasizing cost and time efficiency.Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptx

Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptxppkmurthy2006

Ěý

Mathematics behind machine learning INT255 US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load

Current Delay which delays the creation and storage of created Electromagnetic Field Energy around

the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field

Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the

generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of

an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In

Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be

generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing

zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity

Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any

magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared

to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy

performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to

the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and

the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads,

additional Input Power must be supplied to the Prime Mover and additional Mechanical Input

Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator,

an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive

Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1

MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the

Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric

Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the

Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field

Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the

system.

Engineering at Lovely Professional University (LPU).pdf

Engineering at Lovely Professional University (LPU).pdfSona

Ěý

LPU’s engineering programs provide students with the skills and knowledge to excel in the rapidly evolving tech industry, ensuring a bright and successful future. With world-class infrastructure, top-tier placements, and global exposure, LPU stands as a premier destination for aspiring engineers.decarbonization steel industry rev1.pptx

decarbonization steel industry rev1.pptxgonzalezolabarriaped

Ěý

Webinar Decarbonization steel industryLessons learned when managing MySQL in the Cloud

Lessons learned when managing MySQL in the CloudIgor Donchovski

Ěý

Managing MySQL in the cloud introduces a new set of challenges compared to traditional on-premises setups, from ensuring optimal performance to handling unexpected outages. In this article, we delve into covering topics such as performance tuning, cost-effective scalability, and maintaining high availability. We also explore the importance of monitoring, automation, and best practices for disaster recovery to minimize downtime.15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdf

15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdfNgocThang9

Ěý

Smart Cities Big Data, Civic Hackers, and the Quest for a New UtopiaUS Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Alaa Mohamed CV

- 1. Personal Data Name: Alaa Eldin Mohamed Abdelhafz Data of birth: 1/4/1989 Phone: +2 01002516944 Marital status: Married E-mail: engalaamohamed25@gmail.com Military Status: Exempted Objective Iam looking forward to become a member in a leading company, where my experience and skills will be enhanced and developed, ready to work in any field in anywhere to prove myself. Education BSC of Mechanical engineering- Faculty of Engineering, Menofia University, Egypt 2011. Graduation Project Investigation of Fatigue and wear properties of aluminum and magnesium AL-Mg (Al 5454) Alloy. Project Grade: Excellent Professional Courses ▪ Courses in (HVAC– FIRE FIGHTING– PLUMBING) systems design and shop drawing for all systems by AUTOCAD & REVIT MEP (Basics). ▪ Training at the Industrial Modernization Center (IMC) in the following operations: Turning - Milling - Welding Experience Generally, my experience in (HVAC - Firefighting –- Infrastructure - Plumbing) systems. Working at Hassan Allam Technologies (HAT) as a Senior QA/QC Engineer Project: Mohamed Naguib Data Center with the Egyptian Army. Project: Arab Academy for science and technology JV CCC at North Coast with The League of Arab States. Duties and Responsibilities: ▪ Review the contract documents, drawings, reports and the specification submitted to. ▪ ensure completeness, correctness, comply with the scope of work and requirements and advises of any deficiency. ▪ Review submittals such as shop drawings and materials, ensuring compliance with. ▪ concept design properly coordinated with other disciplines and submitted as per the approved construction schedules, any deviation from project specification shall be notified. ▪ Preparing methods statements and ITP (inspection test plan) ▪ Inspection for all the Mechanical systems of the Project. ▪ Regular visits to Project site and the workshop to ensure quality of work is in compliance with the project quality plan. ▪ Receive and review all material received to the projects according to approved material submittal. ▪ Report the project progress to management. Worked at ORASCOM (OC) as a Senior QA/QC Engineer Project: Al MASA Hotel at Al Alamein city - North Coast with The Egyptian Army. Project: VIDA Al Alamein Hotel Refurbishment-Demolition and Enabling Works -North Coast Owner: EMAAR & Project management: MIRAGE Main Consultant: Ali Nassar Consultants & Partners (El Moshneb Consultancy). Worked at ECE – Elite Consolidated Engineers as a Consultant Engineer Worked as a mechanical consultant representative, site engineer for all Mechanical Systems

- 2. Projects with ECE: 1-Danone Owner: Danone Main Consultant: ECE Elite Consolidated Engineers & Contractor: Consukorra 2-Pepsi –Tanta Owner: PepsiCo Main Consultant: ECE Elite Consolidated Engineers & Contractor: Technonet 3-Horus New Pharmaceutical Plan Owner: EVA Pharma /Armanious Group Main Consultant: ECE Elite Consolidated Engineers & Contractor: Consukorra Duties and Responsibilities: • Inspection of all mechanical activities on site like (HVAC-firefighting– plumbing –infra) systems. • Reviewing shop drawings, invoices and time schedule. • Checking technical submittals and shop drawings submitted by the contractor. • Inspecting and testing the Welders for approval. • Reviewing and approving methods of statement. • Inspecting all equipment and materials delivered to the site. • Respond to RFI’s, MIR’s, IR's, invoice and CVI. • Supervising the work done by contractor to be matching with the design and specification. Worked at HORUS for systems and contracting as a Site Engineer Project: TULIP (Hotel & Mall) at El Rehab city. Duties and Responsibilities: • Responsible of all mechanical activities for firefighting activities. • Inspecting all equipment and materials delivered to the site. • Review the contract documents, Electrical drawings, reports, specification • submitted to ensure completeness, correctness, comply with the scope of work and requirements and advise of any deficiency. • Review submittals such as shop drawings and materials, ensuring compliance with concept design, properly coordinated with other disciplines and submitted as per the approved construction schedules. Any deviation from project specification shall be notified. • Review alternatives to the Design submitted, prepare and submit a report including recommendation highlighting advantages and disadvantages of each alternative addressing any foreseen cost and Time Impact • Submit methods statement. • Coordinate with QC Engineer to establish the intervention point in the proposed Inspection and Test Plan. • properly coordinated with the site inspection team to make sure that it matches all site changes. Worked at EL HELAL AND GOLDEN STAR as a Production Engineer Duties and Responsibilities: • Prepares operational programs, follows-up implementation and provides technical support to field's operations personnel on line production or injection molding and associated problems. • Preparation of Daily, Monthly Production reports. • Production planning & control • Preparation of raw material indents as per the production requirement • Troubleshooting and solving technical problems. Languages: Arabic: Mother Tongue & English: Very Good Skills : Generally, Iam a quick learner to any skill.