ALS MOVUS Case Study - Scrubber Fan

- 1. 1 Right Solutions • Right Partner Right Solutions • Right Partner www.alsglobal.com ALS – FitMachine Case Study: Scrubber Fan Blockage Steel Tube Mill, April 2019

- 2. 2 Right Solutions • Right Partner Application Scrubber Fan Application • FitMachine implemented on scrubber fan provide continuous condition monitoring in-between routine vibration surveys. • Fan is crucial to keeping plant operating

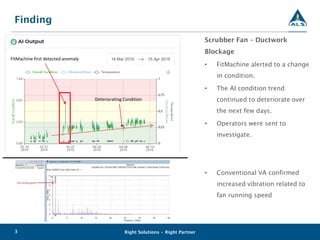

- 3. 3 Right Solutions • Right Partner Finding Scrubber Fan – Ductwork Blockage • FitMachine alerted to a change in condition. • The AI condition trend continued to deteriorate over the next few days. • Operators were sent to investigate. • Conventional VA confirmed increased vibration related to fan running speed FitMachine first detected anomaly Deteriorating Condition

- 4. 4 Right Solutions • Right Partner Result • Operators inspected the fan and found significant dirt build-up on the fan and within the ductwork. • Accessible areas were cleaned immediately to keep the machine running. • The customer was able to avoid costly prolonged downtime and schedule full ductwork clean for a planned shutdown. • MOVUS FitMachine provides cost effective online condition monitoring of rotating equipment that supports handheld vibration data collection and analysis.

- 5. 5 Right Solutions • Right Partner Contact Braham Breytenbach Reliability Systems Lead T +61 7 3816 5500 D +61 7 3816 5529 F +61 7 3282 0118 M +61 438 743 673 braham.breytenbach@alsglobal.com 7 Brisbane Road Riverview, QLD 4303 Right Solutions • Right Partner www.alsglobal.com Peter Caldwell Senior Engineer, Industrial Western Region T +61 8 9232 0300 D +61 8 9232 0343 F +61 8 9232 0396 M +61 0 437 862 138 peter.caldwell@alsglobal.com 109 Bannister Road Canning Vale WA 6155 Right Solutions • Right Partner www.alsglobal.com