AMS┬« CAT BOSSŌäó Cleaner Brochure

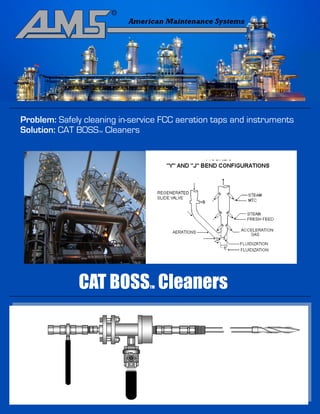

- 1. Problem: Safely cleaning in-service FCC aeration taps and instruments Solution: CAT BOSS Cleaners TM CAT BOSS Cleaners TM

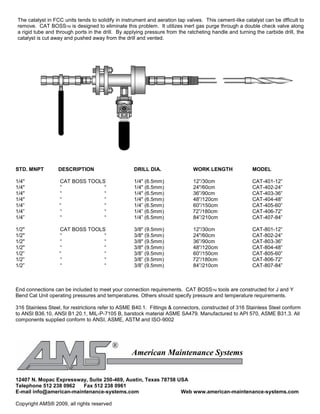

- 2. The catalyst in FCC units tends to solidify in instrument and aeration tap valves. This cement-like catalyst can be dfficult to remove. CAT BOSSTM is designed to eliminate this problem. It utilizes inert gas purge through a double check valve along a rigid tube and through ports in the drill. By applying pressure from the ratcheting handle and turning the carbide drill, the catalyst is cut away and pushed away from the drill and vented. STD. MNPT DESCRIPTION DRILL DIA. WORK LENGTH MODEL 1/4" CAT BOSS TOOLS 1/4" (6.5mm) 12ŌĆØ/30cm CAT-401-12ŌĆØ 1/4" ŌĆ£ ŌĆ£ 1/4" (6.5mm) 24"/60cm CAT-402-24ŌĆØ 1/4" ŌĆ£ ŌĆ£ 1/4" (6.5mm) 36ŌĆØ/90cm CAT-403-36ŌĆØ 1/4" ŌĆ£ ŌĆ£ 1/4" (6.5mm) 48ŌĆØ/120cm CAT-404-48ŌĆØ 1/4ŌĆØ ŌĆ£ ŌĆ£ 1/4ŌĆØ (6.5mm) 60ŌĆØ/150cm CAT-405-60ŌĆØ 1/4ŌĆØ ŌĆ£ ŌĆ£ 1/4ŌĆØ (6.5mm) 72ŌĆØ/180cm CAT-406-72ŌĆØ 1/4ŌĆØ ŌĆ£ ŌĆ£ 1/4ŌĆØ (6.5mm) 84ŌĆØ/210cm CAT-407-84ŌĆØ 1/2" CAT BOSS TOOLS 3/8" (9.5mm) 12ŌĆØ/30cm CAT-801-12ŌĆØ 1/2" ŌĆ£ ŌĆ£ 3/8" (9.5mm) 24"/60cm CAT-802-24ŌĆØ 1/2" ŌĆ£ ŌĆ£ 3/8" (9.5mm) 36ŌĆØ/90cm CAT-803-36ŌĆØ 1/2" ŌĆ£ ŌĆ£ 3/8" (9.5mm) 48ŌĆØ/120cm CAT-804-48ŌĆØ 1/2ŌĆØ ŌĆ£ ŌĆ£ 3/8ŌĆØ (9.5mm) 60ŌĆØ/150cm CAT-805-60ŌĆØ 1/2ŌĆØ ŌĆ£ ŌĆ£ 3/8ŌĆØ (9.5mm) 72ŌĆØ/180cm CAT-806-72ŌĆØ 1/2ŌĆØ ŌĆ£ ŌĆ£ 3/8ŌĆØ (9.5mm) 84ŌĆØ/210cm CAT-807-84ŌĆØ End connections can be included to meet your connection requirements. CAT BOSS TM tools are constructed for J and Y Bend Cat Unit operating pressures and temperatures. Others should specify pressure and temperature requirements. 316 Stainless Steel, for restrictions refer to ASME B40.1. Fittings & connectors, constructed of 316 Stainless Steel conform to ANSI B36.10, ANSI B1.20.1, MIL-P-7105 B, barstock material ASME SA479. Manufactured to API 570, ASME B31.3. All components supplied conform to ANSI, ASME, ASTM and ISO-9002 ┬« American Maintenance Systems 12407 N. Mopac Expressway, Suite 250-469, Austin, Texas 78758 USA Telephone 512 238 0962 Fax 512 238 0961 E-mail info@american-maintenance-systems.com Web www.american-maintenance-systems.com Copyright AMS┬« 2009, all rights reserved