Analysis of titanic failure - –Ґ–Є—В–∞–љ–Є–Ї —Б“ѓ–є—А—Н–ї –і—Н—Н—А—Е –∞–љ–∞–ї–Є–Ј —Е–Є–є—Е

Download as PPTX, PDF2 likes219 views

The document analyzes the failure of the Titanic, beginning with a brief history of its construction and sinking in 1912 after hitting an iceberg. It then discusses several reasons for the Titanic's failure, including its high speed through icy waters, the late detection of the iceberg, lack of lifeboats, and flaws in the steel and design. Specifically, the steel used in the Titanic had a higher ductile-to-brittle transition temperature than modern steel, causing it to fracture rather than bend when hit by the iceberg in cold waters. While better steel and an alternative design without compartments may have prevented the sinking, the engineering mistakes ultimately led to the Titanic's demise and over 1500 casualties.

1 of 10

Download to read offline

Recommended

Why did the titanic sink year ks2

Why did the titanic sink year ks2Lee Hazeldine

ћэ

The document provides background information on the sinking of the Titanic, including a timeline of events and activities exploring the science and history of the disaster. The timeline indicates that the Titanic collided with an iceberg on April 14th, 1912, resulting in damage that caused it to sink on April 15th at 2:20 AM. The document then outlines science and history learning activities focusing on the materials used to build the Titanic, determining how many compartments would need to fill to cause it to sink, and discussing who or what was to blame.Transatlantic Tunnel

Transatlantic TunnelAiswarya A Kumar

ћэ

Transatlantic Tunnel is a theoretical tunnel that spans between Newyork and London.If constructed it would be a massive project in human history.Tunnelling & underground design (Topic1-introduction to the tunnelling industry)

Tunnelling & underground design (Topic1-introduction to the tunnelling industry)Hamed Zarei

ћэ

This document provides an overview of past and present tunnelling projects and challenges. It discusses the stuck Bertha tunnel boring machine in Seattle which has been stuck since 2013 due to overheating. It also discusses cost overruns and litigation on the Seymour-Capilano Twin Tunnels project in BC. Finally, it provides details on the course topics, lectures, and assignments for an introduction to tunnelling class.Titanic disaster causes

Titanic disaster causeskhuram shahzad

ћэ

CAUSES:

MATERIAL FAILURES

DESIGN FLAWS

MATERIAL FAILURES:

When the Titanic collided with the iceberg, the hull steel and the wrought iron rivets failed because of brittle fracture.

. The causes of brittle fracture include low temperature, high impact loading, and high sulphur content.

. On the night of the Titanic disaster, each of these three factors was present:

The water temperature was below freezing, the Titanic was travelling at a high speed on impact with the iceberg, and the hull steel contained high levels of sulphur.

Material Failure

High sulphur content increases the brittleness of steel by disrupting theћэgrain structureћэ.

The sulphur combines with magnesium in the steel to form stringers of magnesium sulphide, which act as "highways" for crack propagation.

Charpy test is used to measure the brittlness of a material.

A cigarette-sized coupon of steel taken from the Titanic wreck and a piece of modern high quality steel.

Design Flaws:

Although the compartments were called watertight, they were actually only watertight horizontally; their tops were open and the walls extended only a few feet above the waterline

. Some of the scientists studying the disaster have even concluded that the watertight compartments contributed to the disaster by keeping the flood waters in the bow of the ship.

Design failure:

If there had been no compartments at all, the incoming water would have spread out, and the Titanic would have remained horizontal.

Curriculum Vitae Jens Classen 2015_01_e

Curriculum Vitae Jens Classen 2015_01_eJens Classen

ћэ

Jens Classen is a German tunneling engineer with over 30 years of experience managing large tunneling projects around the world. He has extensive experience directing tunnel boring machine (TBM) drives and drill-and-blast excavation for major infrastructure projects. Currently, he is the Director of the Mechanized Tunneling Department at Toto S.p.A. Costruzioni Generali, where he oversees the acquisition, design, and project management of underground construction projects.Titanic engineering aspects

Titanic engineering aspectsMohamedSamarin

ћэ

The document discusses the sinking of the Titanic, which collided with an iceberg and sank in 1912. It describes how the Titanic was built using materials like mild steel and iron rivets that were brittle. When the ship collided with the iceberg, the hull and rivets fractured due to their brittleness combined with the cold water temperature. The Titanic also had design flaws like inadequate water-tight compartments that allowed flooding to spread between areas, and it lacked sufficient lifeboats. The combination of material failures, design flaws, and safety issues led to the rapid sinking of the Titanic within three hours.MATERIALS SCI TECH QUIZ

MATERIALS SCI TECH QUIZ Mudassir Khan

ћэ

MAT-Q The materials quiz by Society of surface protective coating chapter , UNIVERSITY OF PETROLEUM AND ENERGY STUDIES - UPES DEHRADUNUnderwater Tunnels

Underwater TunnelsIshan Parekh

ћэ

1. Underwater tunnels are transport routes that are partly or wholly constructed under bodies of water, with different types including soft ground tunnels dug below the ocean bed, immersed tunnels made on the ocean floor, and floating submerged tunnels that float due to attached tethers.

2. Constructing underwater tunnels presents significant engineering challenges due to the tremendous water pressure from above and squeezing pressure from soft ground. Different tunnel construction methods are used depending on the material and conditions.

3. A proposed transatlantic underwater tunnel would connect North America and Europe, but presents massive challenges including the scales of resources, time, and extreme working conditions required that make completion effectively impossible with current technology.Halley VI: An Antarctic research station

Halley VI: An Antarctic research station Association for Project Management

ћэ

The document discusses Halley VI, a new Antarctic research station being built by the British Antarctic Survey. Halley VI Station Manager Karl Tuplin outlines the construction of the modular steel facility, which is being built off-site and transported by ship due to the extreme weather conditions. The construction process involves fabricating modules, installing mechanical and electrical components, and then relocating the completed modules to the Antarctic site. Halley VI will replace older stations and support ongoing research in the region.Tunnelling & underground design (Topic2-geological uncertainty)

Tunnelling & underground design (Topic2-geological uncertainty)Hamed Zarei

ћэ

The Gotthard Base Tunnel project in Switzerland faced significant geological uncertainties and challenges during construction. Known risks included water inflows and weak ground conditions in brittle fault zones, squeezing ground in weak rock masses, and potential rockbursts in deep, high-stress sections. Unknown risks that emerged included unexpectedly thick and extensive buried valleys during the construction of the L√ґtschberg Base Tunnel, which caused a major flood during construction. For the Gotthard Base Tunnel, running ground conditions in water-saturated dolomite formations and the crossing of subhorizontal faults near Faido presented challenges that led to project delays and cost overruns. Addressing these complex geological conditions and unknowns required extensive geological investigations and flexible tunnel constructionUnderground construction

Underground constructionAglaia Connect

ћэ

Underground Construction provides construction, technical and management services to its customers. The company specializes in power, communications, airport fueling and heavy engineering. Since laying its first pipe in 1936, Underground Construction has completed thousands of projects throughout the United States.

interesting civil engineering topics

civil engineering topics for presentation

underground construction magazine

underground construction contractors

underground construction az

underground construction company

underground construction safety

underground construction company california

underground construction technology 2019

push underground construction llc

seminar topics pdf

best seminar topics for civil engineering

civil seminar topics ppt

civil engineering seminar topics 2019

seminar topics for mechanical engineers

mechanical engineering seminar topics 2018

Titanic

TitanicMoiz Barry

ћэ

On the night of April 14, 1912, the RMS Titanic collided with an iceberg in the North Atlantic Ocean and sank within hours. The iceberg struck the starboard side of the Titanic, damaging its hull and opening compartments to flooding. By 2:20 AM on April 15, the Titanic had sunk with the loss of over 1,500 lives. Debate ensued over who or what was responsible for the sinking, focusing on factors like the ship's speed in icy waters, the design of its watertight compartments, and the material used in its construction.STEEL CONSTRUCTION

STEEL CONSTRUCTIONManuel Andres Rubiano

ћэ

The document discusses the history and development of steel as a building material. It describes how early iron extraction methods led to wrought iron with low strength, and how later techniques on like the Bessemer process improved steel production. Major historical structures that demonstrated the growing use of iron and steel in construction are highlighted, from 18th century cast iron bridges to tall skyscrapers in the early 20th century. The properties and classifications of steel per various codes and standards are also covered.UNDERGROUND-CONSTRUCTION.pptx

UNDERGROUND-CONSTRUCTION.pptxIffalconQled

ћэ

This document discusses underground construction, including what can be built underground, why things are built underground, and how underground construction is carried out. It describes various types of underground facilities like shelters, mines, water systems, transit systems, and critical infrastructure. It also discusses the methods used to build underground, such as tunnel boring machines and cut-and-cover construction. Challenges in underground construction include dealing with variable ground conditions, changing groundwater, and fractured rock that is subject to stress and gravity. Risks are best mitigated through thorough site investigation and characterization of subsurface conditions and modeling potential ground behaviors.17 if g popp teutschenthal v4

17 if g popp teutschenthal v4leann_mays

ћэ

This document summarizes the geomechanical safety concept for closing the Teutschenthal backfill mine in Germany. Key aspects include:

1) Hazardous waste is stored underground through "long-term containment" requiring sophisticated geomechanical safety concepts given the mines were not designed as repositories.

2) The Teutschenthal mine involves backfilling over 15 million cubic meters of underground openings using direct, conditioned, and slurry backfilling techniques.

3) Proof of long-term safety involves assessing geological barriers, geomechanical integrity analysis, and long-term scenario analysis based on site geology, hydrogeology, and waste data.

4) A 1996 rockburst was analyzed through modeling and stress/Material failure of titanic ship.

Material failure of titanic ship.ravi bhivra

ћэ

The document outlines the materials used in constructing the Titanic and analyzes the causes of its sinking. It notes that the Titanic was constructed using thousands of mild steel plates and over 2 million steel and wrought iron rivets. The failure of the wrought iron rivets in sealing the hull plates, along with design flaws of the watertight compartments, caused the ship to sink after colliding with an iceberg. Tests showed the wrought iron rivets were more brittle than steel rivets, and likely fractured on impact due to the low temperature of the water. Had it been constructed using modern steels, the Titanic may not have sunk as quickly. There are many famous (more properly, infamous) examples of catastrop.pdf

There are many famous (more properly, infamous) examples of catastrop.pdfanshuanil26

ћэ

There are many famous (more properly, infamous) examples of catastrophic failures of major

engineering structures and systems. Use the Internet to look up each of the following and briefly

describe whether the failure involved brittle or ductile failure initially (as a cause) and brittle or

ductile failure overall (macroscopically). Tacoma (WA) Narrows Bridge, known as Galloping

Gertie Minnesota I-35W Bridge Space Shuttle Challenger Space Shuttle Columbia RMS

Titanic Aloha Airlines Flight 243

Solution

a. Tacoma bridge failure is considered a ductile failure, because the collapse due to the wind

vibrations lasted for long time so that no human casualities were made. Only one dog was the

casuality.

2. The failure of I-35 bridge in Minnesota was a brittle failure because it occured suddenly and

caused enormous catastrophic consequences.

c. Space shuttle Challenger disaster occured due to the occurence of the brittle failure cracks in

O-rings which allowed the fuel leakage and thereby the explosion. No one in the shuttle

surviced, therefore it is a brittle failure. O-rings are ductile in nature but, at low temperature they

become brittle, so such failures come in category of ductile-to-brittle transition failures.

d. Space Shuttle Columbia failure occured due to the damage to the thermal shielding tiles from

impact with a piece of foam, which fell from the insulation of an external tank during the take

off. Failure occured while returning to the earth, while its speed was very very high, and wing

experienced a high temperature of 1540 degree celsius. Damage to the thermal shield panel was

tested to be a brittle failure, and therefore it also comes in category of brittle failure.

e. RMS titanic was floating at very cold temperature and when near freezing temperature was

met, tests showed that steel became extremely brittle. It was also a ductile-to-brittle transition

failure. Overall ship sunk in 2 hours and about 15 minutes, so overall it could be considered a

ductile failure, but no help was available in that time.

f. It was a gatigue failure, which progressed in 19 years, but the end failure was brittle, therefore

a brittle failure. Overall (maroscopically) failure was a ductile failure, since it happened due to

the corrosion and fatigue of 19 years..Titanic.pptx

Titanic.pptxgamingchannel24

ћэ

The Titanic tragedy is a poignant tale that intertwines ambition, engineering marvels, and human tragedy. The ship was a marvel of its time, considered unsinkable due to its innovative design and luxurious amenities. However, its fate serves as a reminder of the limitations of human ingenuity and the unpredictable forces of nature.

The Titanic was an engineering masterpiece, designed with cutting-edge technology for its era. Constructed by the Harland and Wolff shipyard in Belfast, Ireland, it was a feat of engineering boasting a length of about 882 feet and a width of 92.5 feet. The ship was divided into 16 compartments, supposedly watertight, a design that was believed to make it virtually unsinkable even if several compartments were breached.

Its hull was constructed using high-quality steel, a material believed to be strong and resilient. However, the steel used in the construction had a high sulfur content, making it more brittle in cold temperaturesвАФa crucial factor contributing to the catastrophic iceberg collision.

The ship's opulence was unparalleled, with lavish interiors featuring intricate woodwork, plush furnishings, and state-of-the-art amenities for its passengers. Despite its grandeur, the Titanic was not equipped with enough lifeboats to accommodate all passengers and crew, a tragic oversight that exacerbated the loss of life when disaster struck.

On the fateful night of April 14, 1912, the Titanic, on its maiden voyage from Southampton to New York City, collided with an iceberg in the frigid North Atlantic waters. The impact caused severe damage, breaching multiple compartments and compromising the supposedly watertight design.

The fatal flaw became evident as the compartments filled with water, causing the ship to gradually sink. The inadequate number of lifeboats exacerbated the catastrophe, leading to the loss of over 1,500 lives out of the approximately 2,224 passengers and crew on board.

The Titanic tragedy remains a poignant reminder of the limitations of human hubris, despite advancements in technology and design. It serves as a crucial lesson in maritime safety, influencing subsequent regulations and practices to ensure the safety of passengers and crew on modern-day ships.Construction Forensic

Construction ForensicDr. ABEER KHALID MANSOUR

ћэ

Introduction to the application of forensic in the construction industry , its importance and benefits .mechanical aspect of corrosion.pptx

mechanical aspect of corrosion.pptxssuserd104c2

ћэ

This document provides information about Dr. Abdolali Fayyaz and his research interests in materials science and manufacturing engineering. It also includes a course description for a seminar on mechanical aspects of corrosion taught by Dr. Fayyaz. The course will cover topics like stress corrosion cracking, corrosion fatigue cracking, and hydrogen embrittlement and their role in environmentally induced cracking of materials. It lists some past disasters where environment-assisted cracking like stress corrosion led to catastrophic failures in infrastructure and industrial equipment.PPT CAVITY Tunnel P1 610M--05.02.2021.pptx

PPT CAVITY Tunnel P1 610M--05.02.2021.pptxAGNIVORAY1

ћэ

The excavation of Tunnel T1 in Sivok-Rangpo Rail Link Project encountered a cavity formation due to a sudden shear zone at chainage 610.8 meters. The cavity initially extended to 608.6 meters before remedial measures were taken to backfill the face and install temporary supports. Further collapses occurred despite efforts to control the cavity, eventually extending it to the surface and creating a ditch approximately 7x7 meters. Monitoring shows the tunnel deformations remain within safe limits. The unexpected shear zone in the complex Himalayan geology was determined to be the cause of the cavity.20150908 Tianjin Explosion Analysis_1st DRAFT_show - Copy

20150908 Tianjin Explosion Analysis_1st DRAFT_show - CopyNigel Cann

ћэ

The document analyzes the explosions that occurred in Tianjin, China on August 12, 2015 involving a warehouse storing hazardous chemicals. Through calculations based on the size of the crater and modeling of blast effects, the document estimates that the explosive quantity was around 180 tons of ammonium nitrate, much larger than the initial estimate of 21 tons. The impacts observed in photos and videos such as destroyed buildings up to 500-650 meters away match expected damage ranges calculated for an 180 ton explosion.Deep drilling - Risks and challenges with examples from the German Molasse Basin

Deep drilling - Risks and challenges with examples from the German Molasse BasinGerd Tarand

ћэ

Deep drilling projects in the German Molasse Basin present technical challenges and risks. Drilling very deep wells over 4,000 meters involves problems like borehole failures, fluid losses, and casing stability issues. These problems increased costs for projects like Sauerlach where sidetracks were needed and costs doubled. Managing risks requires detailed feasibility studies, flexible drilling contracts, and drilling rigs capable of addressing geological problems encountered at depth.The Akashi Kaikyo bridge - longest suspension bridge in the world

The Akashi Kaikyo bridge - longest suspension bridge in the worldADARSH _

ћэ

Case Study of the Longest Suspension Bridge in the world - The Akashi Kaikyo Bridge. In this presentation, various structural features of this bridge are discussed and a few videos provided helps us to get a better understanding of it.Tunneling

Tunnelingjagdish lawadiya

ћэ

The document discusses different types of tunnels used for transportation, including those resting on the sea bed, floating in the sea, and tunnels dug below the sea bed. It focuses on submerged floating tunnels, which are tube-like structures that float underwater at a certain depth, fixed by cables. This allows tunnels to be constructed in extremely deep waters where conventional bridges or tunnels are not feasible. The document outlines the principles behind submerged floating tunnels and describes their construction process which involves building segments on dry dock and joining them together underwater. Examples of significant tunnels discussed include the Channel Tunnel between Britain and France, and the Seikan Tunnel in Japan. Tunnel boring machines are also described as the method used to excavate underwater and below sea bed tunnelsUnderground construction

Underground constructionPavan Kumar N

ћэ

This document discusses what can go underground, why things go underground, and how underground construction is carried out. It outlines that shelters, homes, mines, water systems, transit systems, roads, power plants, fuel and material storage, critical infrastructure, research facilities, and public facilities can all be built underground. Key reasons for going underground include addressing urban congestion, creating green space, protection from natural disasters, and isolation. Various methods are used for underground construction including cut-and-cover, tunnel boring machines, retaining walls, and blasting. Challenges can arise from unexpected ground conditions, major excavations, changing groundwater, and need to characterize and account for geologic variability and uncertainties. Risks are best mitigatedLondon Underground

London UndergroundElvis London

ћэ

The London Underground, also known as the Tube, is the oldest underground railway system in the world. It has over 270 stations and 11 lines spanning more than 400 km. While the first underground train opened in 1863, much of the network was constructed over 100 years ago and requires extensive maintenance. Technological challenges included building tunnels near historical structures without damage and addressing water issues near the river Thames. The Underground also played an important role as a bomb shelter during World War II and its iconic map design helped popularize the system.Improving Surgical Robot Performance Through Seal Design.pdf

Improving Surgical Robot Performance Through Seal Design.pdfBSEmarketing

ћэ

Ever wonder how something as "simple" as a seal can impact surgical robot accuracy and reliability? Take quick a spin through this informative deck today, and use what you've learned to build a better robot tomorrow.Turbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

ћэ

High Efficiency Chiller System in HVACMore Related Content

Similar to Analysis of titanic failure - –Ґ–Є—В–∞–љ–Є–Ї —Б“ѓ–є—А—Н–ї –і—Н—Н—А—Е –∞–љ–∞–ї–Є–Ј —Е–Є–є—Е (20)

Halley VI: An Antarctic research station

Halley VI: An Antarctic research station Association for Project Management

ћэ

The document discusses Halley VI, a new Antarctic research station being built by the British Antarctic Survey. Halley VI Station Manager Karl Tuplin outlines the construction of the modular steel facility, which is being built off-site and transported by ship due to the extreme weather conditions. The construction process involves fabricating modules, installing mechanical and electrical components, and then relocating the completed modules to the Antarctic site. Halley VI will replace older stations and support ongoing research in the region.Tunnelling & underground design (Topic2-geological uncertainty)

Tunnelling & underground design (Topic2-geological uncertainty)Hamed Zarei

ћэ

The Gotthard Base Tunnel project in Switzerland faced significant geological uncertainties and challenges during construction. Known risks included water inflows and weak ground conditions in brittle fault zones, squeezing ground in weak rock masses, and potential rockbursts in deep, high-stress sections. Unknown risks that emerged included unexpectedly thick and extensive buried valleys during the construction of the L√ґtschberg Base Tunnel, which caused a major flood during construction. For the Gotthard Base Tunnel, running ground conditions in water-saturated dolomite formations and the crossing of subhorizontal faults near Faido presented challenges that led to project delays and cost overruns. Addressing these complex geological conditions and unknowns required extensive geological investigations and flexible tunnel constructionUnderground construction

Underground constructionAglaia Connect

ћэ

Underground Construction provides construction, technical and management services to its customers. The company specializes in power, communications, airport fueling and heavy engineering. Since laying its first pipe in 1936, Underground Construction has completed thousands of projects throughout the United States.

interesting civil engineering topics

civil engineering topics for presentation

underground construction magazine

underground construction contractors

underground construction az

underground construction company

underground construction safety

underground construction company california

underground construction technology 2019

push underground construction llc

seminar topics pdf

best seminar topics for civil engineering

civil seminar topics ppt

civil engineering seminar topics 2019

seminar topics for mechanical engineers

mechanical engineering seminar topics 2018

Titanic

TitanicMoiz Barry

ћэ

On the night of April 14, 1912, the RMS Titanic collided with an iceberg in the North Atlantic Ocean and sank within hours. The iceberg struck the starboard side of the Titanic, damaging its hull and opening compartments to flooding. By 2:20 AM on April 15, the Titanic had sunk with the loss of over 1,500 lives. Debate ensued over who or what was responsible for the sinking, focusing on factors like the ship's speed in icy waters, the design of its watertight compartments, and the material used in its construction.STEEL CONSTRUCTION

STEEL CONSTRUCTIONManuel Andres Rubiano

ћэ

The document discusses the history and development of steel as a building material. It describes how early iron extraction methods led to wrought iron with low strength, and how later techniques on like the Bessemer process improved steel production. Major historical structures that demonstrated the growing use of iron and steel in construction are highlighted, from 18th century cast iron bridges to tall skyscrapers in the early 20th century. The properties and classifications of steel per various codes and standards are also covered.UNDERGROUND-CONSTRUCTION.pptx

UNDERGROUND-CONSTRUCTION.pptxIffalconQled

ћэ

This document discusses underground construction, including what can be built underground, why things are built underground, and how underground construction is carried out. It describes various types of underground facilities like shelters, mines, water systems, transit systems, and critical infrastructure. It also discusses the methods used to build underground, such as tunnel boring machines and cut-and-cover construction. Challenges in underground construction include dealing with variable ground conditions, changing groundwater, and fractured rock that is subject to stress and gravity. Risks are best mitigated through thorough site investigation and characterization of subsurface conditions and modeling potential ground behaviors.17 if g popp teutschenthal v4

17 if g popp teutschenthal v4leann_mays

ћэ

This document summarizes the geomechanical safety concept for closing the Teutschenthal backfill mine in Germany. Key aspects include:

1) Hazardous waste is stored underground through "long-term containment" requiring sophisticated geomechanical safety concepts given the mines were not designed as repositories.

2) The Teutschenthal mine involves backfilling over 15 million cubic meters of underground openings using direct, conditioned, and slurry backfilling techniques.

3) Proof of long-term safety involves assessing geological barriers, geomechanical integrity analysis, and long-term scenario analysis based on site geology, hydrogeology, and waste data.

4) A 1996 rockburst was analyzed through modeling and stress/Material failure of titanic ship.

Material failure of titanic ship.ravi bhivra

ћэ

The document outlines the materials used in constructing the Titanic and analyzes the causes of its sinking. It notes that the Titanic was constructed using thousands of mild steel plates and over 2 million steel and wrought iron rivets. The failure of the wrought iron rivets in sealing the hull plates, along with design flaws of the watertight compartments, caused the ship to sink after colliding with an iceberg. Tests showed the wrought iron rivets were more brittle than steel rivets, and likely fractured on impact due to the low temperature of the water. Had it been constructed using modern steels, the Titanic may not have sunk as quickly. There are many famous (more properly, infamous) examples of catastrop.pdf

There are many famous (more properly, infamous) examples of catastrop.pdfanshuanil26

ћэ

There are many famous (more properly, infamous) examples of catastrophic failures of major

engineering structures and systems. Use the Internet to look up each of the following and briefly

describe whether the failure involved brittle or ductile failure initially (as a cause) and brittle or

ductile failure overall (macroscopically). Tacoma (WA) Narrows Bridge, known as Galloping

Gertie Minnesota I-35W Bridge Space Shuttle Challenger Space Shuttle Columbia RMS

Titanic Aloha Airlines Flight 243

Solution

a. Tacoma bridge failure is considered a ductile failure, because the collapse due to the wind

vibrations lasted for long time so that no human casualities were made. Only one dog was the

casuality.

2. The failure of I-35 bridge in Minnesota was a brittle failure because it occured suddenly and

caused enormous catastrophic consequences.

c. Space shuttle Challenger disaster occured due to the occurence of the brittle failure cracks in

O-rings which allowed the fuel leakage and thereby the explosion. No one in the shuttle

surviced, therefore it is a brittle failure. O-rings are ductile in nature but, at low temperature they

become brittle, so such failures come in category of ductile-to-brittle transition failures.

d. Space Shuttle Columbia failure occured due to the damage to the thermal shielding tiles from

impact with a piece of foam, which fell from the insulation of an external tank during the take

off. Failure occured while returning to the earth, while its speed was very very high, and wing

experienced a high temperature of 1540 degree celsius. Damage to the thermal shield panel was

tested to be a brittle failure, and therefore it also comes in category of brittle failure.

e. RMS titanic was floating at very cold temperature and when near freezing temperature was

met, tests showed that steel became extremely brittle. It was also a ductile-to-brittle transition

failure. Overall ship sunk in 2 hours and about 15 minutes, so overall it could be considered a

ductile failure, but no help was available in that time.

f. It was a gatigue failure, which progressed in 19 years, but the end failure was brittle, therefore

a brittle failure. Overall (maroscopically) failure was a ductile failure, since it happened due to

the corrosion and fatigue of 19 years..Titanic.pptx

Titanic.pptxgamingchannel24

ћэ

The Titanic tragedy is a poignant tale that intertwines ambition, engineering marvels, and human tragedy. The ship was a marvel of its time, considered unsinkable due to its innovative design and luxurious amenities. However, its fate serves as a reminder of the limitations of human ingenuity and the unpredictable forces of nature.

The Titanic was an engineering masterpiece, designed with cutting-edge technology for its era. Constructed by the Harland and Wolff shipyard in Belfast, Ireland, it was a feat of engineering boasting a length of about 882 feet and a width of 92.5 feet. The ship was divided into 16 compartments, supposedly watertight, a design that was believed to make it virtually unsinkable even if several compartments were breached.

Its hull was constructed using high-quality steel, a material believed to be strong and resilient. However, the steel used in the construction had a high sulfur content, making it more brittle in cold temperaturesвАФa crucial factor contributing to the catastrophic iceberg collision.

The ship's opulence was unparalleled, with lavish interiors featuring intricate woodwork, plush furnishings, and state-of-the-art amenities for its passengers. Despite its grandeur, the Titanic was not equipped with enough lifeboats to accommodate all passengers and crew, a tragic oversight that exacerbated the loss of life when disaster struck.

On the fateful night of April 14, 1912, the Titanic, on its maiden voyage from Southampton to New York City, collided with an iceberg in the frigid North Atlantic waters. The impact caused severe damage, breaching multiple compartments and compromising the supposedly watertight design.

The fatal flaw became evident as the compartments filled with water, causing the ship to gradually sink. The inadequate number of lifeboats exacerbated the catastrophe, leading to the loss of over 1,500 lives out of the approximately 2,224 passengers and crew on board.

The Titanic tragedy remains a poignant reminder of the limitations of human hubris, despite advancements in technology and design. It serves as a crucial lesson in maritime safety, influencing subsequent regulations and practices to ensure the safety of passengers and crew on modern-day ships.Construction Forensic

Construction ForensicDr. ABEER KHALID MANSOUR

ћэ

Introduction to the application of forensic in the construction industry , its importance and benefits .mechanical aspect of corrosion.pptx

mechanical aspect of corrosion.pptxssuserd104c2

ћэ

This document provides information about Dr. Abdolali Fayyaz and his research interests in materials science and manufacturing engineering. It also includes a course description for a seminar on mechanical aspects of corrosion taught by Dr. Fayyaz. The course will cover topics like stress corrosion cracking, corrosion fatigue cracking, and hydrogen embrittlement and their role in environmentally induced cracking of materials. It lists some past disasters where environment-assisted cracking like stress corrosion led to catastrophic failures in infrastructure and industrial equipment.PPT CAVITY Tunnel P1 610M--05.02.2021.pptx

PPT CAVITY Tunnel P1 610M--05.02.2021.pptxAGNIVORAY1

ћэ

The excavation of Tunnel T1 in Sivok-Rangpo Rail Link Project encountered a cavity formation due to a sudden shear zone at chainage 610.8 meters. The cavity initially extended to 608.6 meters before remedial measures were taken to backfill the face and install temporary supports. Further collapses occurred despite efforts to control the cavity, eventually extending it to the surface and creating a ditch approximately 7x7 meters. Monitoring shows the tunnel deformations remain within safe limits. The unexpected shear zone in the complex Himalayan geology was determined to be the cause of the cavity.20150908 Tianjin Explosion Analysis_1st DRAFT_show - Copy

20150908 Tianjin Explosion Analysis_1st DRAFT_show - CopyNigel Cann

ћэ

The document analyzes the explosions that occurred in Tianjin, China on August 12, 2015 involving a warehouse storing hazardous chemicals. Through calculations based on the size of the crater and modeling of blast effects, the document estimates that the explosive quantity was around 180 tons of ammonium nitrate, much larger than the initial estimate of 21 tons. The impacts observed in photos and videos such as destroyed buildings up to 500-650 meters away match expected damage ranges calculated for an 180 ton explosion.Deep drilling - Risks and challenges with examples from the German Molasse Basin

Deep drilling - Risks and challenges with examples from the German Molasse BasinGerd Tarand

ћэ

Deep drilling projects in the German Molasse Basin present technical challenges and risks. Drilling very deep wells over 4,000 meters involves problems like borehole failures, fluid losses, and casing stability issues. These problems increased costs for projects like Sauerlach where sidetracks were needed and costs doubled. Managing risks requires detailed feasibility studies, flexible drilling contracts, and drilling rigs capable of addressing geological problems encountered at depth.The Akashi Kaikyo bridge - longest suspension bridge in the world

The Akashi Kaikyo bridge - longest suspension bridge in the worldADARSH _

ћэ

Case Study of the Longest Suspension Bridge in the world - The Akashi Kaikyo Bridge. In this presentation, various structural features of this bridge are discussed and a few videos provided helps us to get a better understanding of it.Tunneling

Tunnelingjagdish lawadiya

ћэ

The document discusses different types of tunnels used for transportation, including those resting on the sea bed, floating in the sea, and tunnels dug below the sea bed. It focuses on submerged floating tunnels, which are tube-like structures that float underwater at a certain depth, fixed by cables. This allows tunnels to be constructed in extremely deep waters where conventional bridges or tunnels are not feasible. The document outlines the principles behind submerged floating tunnels and describes their construction process which involves building segments on dry dock and joining them together underwater. Examples of significant tunnels discussed include the Channel Tunnel between Britain and France, and the Seikan Tunnel in Japan. Tunnel boring machines are also described as the method used to excavate underwater and below sea bed tunnelsUnderground construction

Underground constructionPavan Kumar N

ћэ

This document discusses what can go underground, why things go underground, and how underground construction is carried out. It outlines that shelters, homes, mines, water systems, transit systems, roads, power plants, fuel and material storage, critical infrastructure, research facilities, and public facilities can all be built underground. Key reasons for going underground include addressing urban congestion, creating green space, protection from natural disasters, and isolation. Various methods are used for underground construction including cut-and-cover, tunnel boring machines, retaining walls, and blasting. Challenges can arise from unexpected ground conditions, major excavations, changing groundwater, and need to characterize and account for geologic variability and uncertainties. Risks are best mitigatedLondon Underground

London UndergroundElvis London

ћэ

The London Underground, also known as the Tube, is the oldest underground railway system in the world. It has over 270 stations and 11 lines spanning more than 400 km. While the first underground train opened in 1863, much of the network was constructed over 100 years ago and requires extensive maintenance. Technological challenges included building tunnels near historical structures without damage and addressing water issues near the river Thames. The Underground also played an important role as a bomb shelter during World War II and its iconic map design helped popularize the system.Recently uploaded (20)

Improving Surgical Robot Performance Through Seal Design.pdf

Improving Surgical Robot Performance Through Seal Design.pdfBSEmarketing

ћэ

Ever wonder how something as "simple" as a seal can impact surgical robot accuracy and reliability? Take quick a spin through this informative deck today, and use what you've learned to build a better robot tomorrow.Turbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

ћэ

High Efficiency Chiller System in HVACDesigning Flex and Rigid-Flex PCBs to Prevent Failure

Designing Flex and Rigid-Flex PCBs to Prevent FailureEpec Engineered Technologies

ћэ

Flex and rigid-flex printed circuit boards (PCBs) can be considered at the basic level some of the most complex PCBs in the industry. With that in mind, itвАЩs incredibly easy to make a mistake, to leave something out, or to create a design that was doomed from the start.

Such design failures can end up leading to an eventual failure by delamination, short circuits, damage to the flex portions, and many other things. The easiest way to circumvent these is to start at the beginning, to design with preventing failure in mind rather than trying to fix existing designs to accommodate for problems.

In this webinar, we cover how to design flex and rigid-flex PCBs with failure prevention in mind to save time, money, and headaches, and what failure can look like.

For more information on our flex and rigid-flex PCB solutions, visit https://www.epectec.com/flex.A Star Algorithm in Artificial intelligence

A Star Algorithm in Artificial intelligencevipulkondekar

ћэ

A Star Algorithm in Artificial intelligenceSppu engineering artificial intelligence and data science semester 6th Artif...

Sppu engineering artificial intelligence and data science semester 6th Artif...pawaletrupti434

ћэ

Sppu University Third year AI&DS Artificial Neural Network unit 1How to Build a Speed Sensor using Arduino?

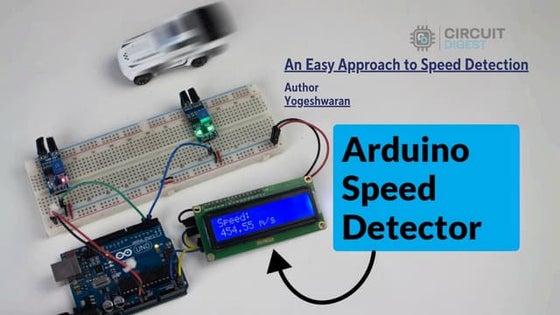

How to Build a Speed Sensor using Arduino?CircuitDigest

ћэ

Learn how to measure speed using IR sensors in this simple DIY project. This tutorial cover circuit diagram, Sensor calibration and speed calculations and optimized Arduino code for real time speed measurements.Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

ћэ

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. IoT-based-Electrical-Motor-Fault-Detection-System.pptx

IoT-based-Electrical-Motor-Fault-Detection-System.pptxatharvapardeshi03

ћэ

IoT-based-Electrical-Motor-Fault-Detection-System.pptxCommon Network Architecture:X.25 Networks, Ethernet (Standard and Fast): fram...

Common Network Architecture:X.25 Networks, Ethernet (Standard and Fast): fram...SnehPrasad2

ћэ

X.25 Networks, Ethernet (Standard and Fast): frame format and specifications, Wireless LANвАЩs вАУ 802.11x, 802.3 Bluetooth etc.

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2prasadmutkule1

ћэ

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2Machine Vision lecture notes for Unit 3.ppt

Machine Vision lecture notes for Unit 3.pptSATHISHKUMARSD1

ћэ

This is the document related to machine vision subject for final year mechatronics students.Cloud Cost Optimization for GCP, AWS, Azure

Cloud Cost Optimization for GCP, AWS, Azurevinothsk19

ћэ

Reduce Cloud Waste across AWS, GCP, Azure and Optimize Cloud Cost with a structured approach and improve your bottomline or profitability. Decide whether you want to outsource or manage it in house. The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

ћэ

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptx

Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptxRofino Licuco

ћэ

Mozambique, a country with vast natural resources and immense potential, nevertheless faces several economic challenges, including high unemployment, limited access to energy, and an unstable power supply. Underdeveloped infrastructure has slowed the growth of industry and hampered peopleвАЩs entrepreneurial ambitions, leaving many regions in the darkвАФliterally and figuratively.

https://www.rofinolicuco.net/blog/how-renewable-energy-can-help-mozambique-grow-its-economyESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3prasadmutkule1

ћэ

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3Design of cannal by Kennedy Theory full problem solved

Design of cannal by Kennedy Theory full problem solvedEr. Gurmeet Singh

ћэ

Design of cannal by Kennedy Theory

By Er Gurmeet Singh

G.C.E.T JAMMU

CONTACT: Gurmeet.b.tech@gmail.com

AI-Powered Power Converter Design Workflow.pdf

AI-Powered Power Converter Design Workflow.pdfAleksandr Terlo

ћэ

Blending human expertise with AI-driven optimization for efficient power converter design.Analysis of titanic failure - –Ґ–Є—В–∞–љ–Є–Ї —Б“ѓ–є—А—Н–ї –і—Н—Н—А—Е –∞–љ–∞–ї–Є–Ј —Е–Є–є—Е

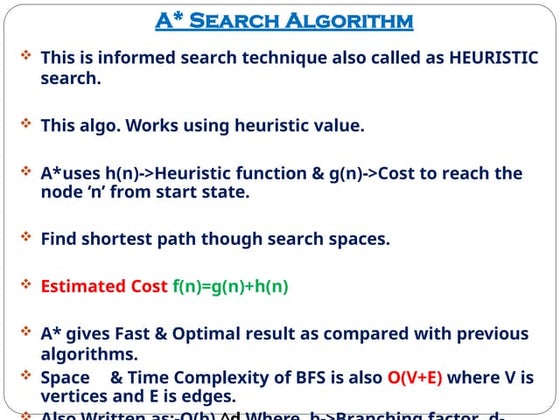

- 1. Implemented by: German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn ANALYSIS OF THE TITANIC FAILURE BAT-OCHIR BATTUMUR GMIT вАУ BACH1 03/15/18

- 2. Implemented by: AGENDA 1. BRIEF HISTORY OF TITANIC 2. REASONS WHY THE TITANIC FAILED 3. TITANIC STEEL VS MODERN STEEL 4. DESIGN FLAWS OF TITANIC 5. CONCLUSION 6. NEXT TITANIC IN THE FUTURE 7. THANKS, Q&A German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn

- 3. Implemented by: BRIEF HISTORY OF TITANIC German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn 31 March 1909 вАҐ Construction of titanic begins 31 May 1911 вАҐ Firstly launched 10 April 1912 вАҐ left Southampton вАҐ called at Cherbourg (France) and Queenstown (Ireland) вАҐ Headed to New York 14 April, 11.40pm вАҐ hit an iceberg 15 April, 2.20am вАҐ broke apart and sank with over 1500 people September 1, 1985 вАҐ The wreck of Titanic was first discovered at depth of 3784m

- 4. Implemented by: REASONS WHY THE TITANIC FAILED German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn вАҐ FULL SPEED вАҐ (42KM/H) DURING NIGHT TIME вАҐ ICEBERG WAS SPOTTED TOO LATE (37 SECONDS BEFORE HIT) вАҐ THE LACK OF LIFEBOATS вАҐ HULL STEEL вАҐ DESIGN

- 5. Implemented by: TITANIC STEEL VS MODERN STEEL German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn TITANIC STEEL SAE 1020 GRAIN SIZE 50¬µm 25¬µm Yield Strength 193.1 MPa 206.9 MPa Tensile Strength 417.1 MPa 379.2 MPa MN:S RATIO LOWER HIGHER DUCTILE-TO- BRITTLE TEMPERATURE GREATER (32¬∞C for longitudinal 56¬∞C for transverse) LESS Sea-water temperature (-2¬∞C) below DUCTILE-TO- BRITTLE TEMPERATURE (32¬∞C and 56¬∞C) led to brittle failure

- 6. Implemented by: DESIGN FLAWS OF TITANIC German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn вАҐ The lower section of the Titanic was divided into sixteen compartments that could easily be sealed off вАҐ If there had been no compartments at all, the incoming water would have spread out (Titanic would have remained horizontal for another 6 hours) TITANIC STEEL WHICH SHOWS BRITTLE BEHAVIOR UNDER 32¬∞C

- 7. Implemented by: CONCLUSION вАҐ THE MAIN ENGINEERING MISTAKES OF TITANIC WERE 1. HULL STEEL (SHOWS BRITTLE BEHAVIOR UNDER 32¬∞C) 2. BAD DESIGN IN LOWER SECTION German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn вАҐ SOLUTION WOULD BE 1. PROPER STEEL (WHICH HAS LOWER DUCTILE-TO-BRITTLE TEMPERATURE) 2. NO COMPARTMENTS

- 8. Implemented by: TITANIC II (Romandisea Titanic) German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn CHINAвАЩS REPLICA IS SCHEDULED TO BE FINISHED BY THE END OF THIS YEAR AND OPENED TO THE PUBLIC IN 2019

- 9. Implemented by: German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn THANK YOU FOR YOUR ATTENTION!

- 10. Implemented by: вАҐ https://en.wikipedia.org/wiki/RMS_Titanic вАҐ http://www.tms.org/pubs/journals/JOM/9801/Felkins-9801.html вАҐ https://www.simscale.com/blog/2018/01/why-did-titanic-sink-engineer/ вАҐ https://www.telegraph.co.uk/news/uknews/8933109/The-30-seconds-that- sank-the-Titanic-fatal-delay-in-order-to-change-course-doomed-liner.html вАҐ https://www.telegraph.co.uk/travel/cruises/news/titanic-replica-latest-update/ German-Mongolian Institute for Resources and Technology вИТ www.gmit.edu.mn REFERENCE