Application of Micro fabricated valves based on the principles of thermo pneumatic actuation

0 likes495 views

1) The document discusses thermopneumatic microvalves and their applications. It describes the fabrication process and working of thermopneumatic microvalves. 2) Applications discussed include use as expansion valves in refrigeration systems and for gas distribution and control in semiconductor processing. 3) The advantages of microvalves include increased performance, higher integration levels, decreased size and increased reliability compared to traditional valves. Challenges include required power, response speed and effects of shrinking size.

1 of 17

Download to read offline

Recommended

IRJET- Computational Fluid Dynamic Analysis of Performance of Centrifugal Pum...

IRJET- Computational Fluid Dynamic Analysis of Performance of Centrifugal Pum...IRJET Journal

Ěý

This document describes a computational fluid dynamics (CFD) analysis of the performance of a centrifugal pump impeller on a cooling system. The study analyzes the design and performance of a centrifugal pump by changing the impeller blade angle using CFD software. The objectives are to perform CFD analysis of the impeller, study the effect of changing the impeller blade angle, develop an impeller design approach, optimize the design, and validate it through experiment and simulation. Various impeller blade angle combinations are simulated and the resulting pressures are recorded and analyzed. The results show how discharge is highly affected by flow velocity and how pressure varies for different impeller blade angles.Case Study: Blast Furnace Gas Distribution

Case Study: Blast Furnace Gas DistributionFlex Process

Ěý

Flex Process developed a complex dynamic simulation of a gas distribution network handling the off-gas from multiple blast furnaces. By modelling the continuous changes across the low-pressure system, we were able to identify the co-incident events which had the biggest effects, and recommend modifications to improve energy use.Ijmet 08 02_029NUMERICAL SOLUTIONS FOR PERFORMANCE PREDICTION OF CENTRIFUGAL ...

Ijmet 08 02_029NUMERICAL SOLUTIONS FOR PERFORMANCE PREDICTION OF CENTRIFUGAL ...IAEME Publication

Ěý

An attempt is made in the present study to investigate the superior turbulence model for

simulating three dimensional flows in centrifugal compressor. The strong channelled curvature and

intensive rotations prevalent in centrifugal compressor resulting high swirling and secondary flow

nictitates choosing appropriate turbulence model for accurate performance predictions. The

various turbulence models offered in FLUENT viz Spalart Allmaras (curvature correction),

Transition SST (curvature correction), Scaled Adaptive Simulations (Curvature correction with

compressibility effect), Reynolds stress model (compressibility effect) were investigated presently

for Eckardt Impeller. Reynolds stress model though involves higher computational time was found

to be the superior model. It is essential to investigate the onset of surge and choke for completely

understanding the performance of a centrifugal compressor. Choking phenomena was observed

when the speed reached 16000 rpm with relative Mach number reaching unity in the impeller

region. The maximum flow rate at 16000 rpm was 0.4 kg/s per blade and remained constant then

16500 rpm. Surging was founded to initiate when the back pressure has to reach 1.8 bar resulting

in zero dischargeNUMERICAL SOLUTIONS FOR PERFORMANCE PREDICTION OF CENTRIFUGAL COMPRESSOR

NUMERICAL SOLUTIONS FOR PERFORMANCE PREDICTION OF CENTRIFUGAL COMPRESSORIAEME Publication

Ěý

An attempt is made in the present study to investigate the superior turbulence model forsimulating three dimensional flows in centrifugal compressor. The strong channelled curvature andintensive rotations prevalent in centrifugal compressor resulting high swirling and secondary flownictitates choosing appropriate turbulence model for accurate performance predictions. Thevarious turbulence models offered in FLUENT viz Spalart Allmaras (curvature correction),Transition SST (curvature correction), Scaled Adaptive Simulations (Curvature correction withcompressibility effect), Reynolds stress model (compressibility effect) were investigated presentlyfor Eckardt Impeller. Reynolds stress model though involveshigher computational time was found

to be the superior model. It is essential to investigate the onset of surge and choke for completelyunderstanding the performance of a centrifugal compressor. Choking phenomena was observedwhen the speed reached 16000 rpm with relative Mach number reaching unity in the impellerregion. The maximum flow rate at 16000 rpm was 0.4 kg/s per blade and remained constant then16500 rpm. Surging was founded to initiate when the back pressure has to reach 1.8 bar resultingin zero dischargeCombinated energy presure

Combinated energy presurekamila64

Ěý

This document summarizes several work packages and deliverables related to pressure management. It discusses developing optimization algorithms to define optimal pressure zones and control schemes. It also covers integrating pump control with pressure control to minimize treatment and energy costs while maintaining good customer service and leakage. Case studies will apply these methods to real networks in Harrogate and Oldham.Lucien Morales S.B. Thesis

Lucien Morales S.B. ThesisLucien Morales

Ěý

This document describes an experimental study on visualizing and measuring the effects of air gap membrane distillation module inclination angle and gap spacer orientation. Experiments were conducted with a membrane distillation test apparatus that included adjustable module angle and different mesh spacers to create air gaps of varying thickness. The experiments investigated the impact of module tilt angle from -70 to 85 degrees and gap spacer orientation on the permeate production rate. Imaging of the condensation in the air gap was also conducted and compared across conditions. Preliminary results showed no significant difference in permeate production for tilt angles between 0 and 15 degrees, while production increased with negative tilt angles due to thermal bridging effects. Gap spacer orientation was also found to have little effect on production rate.Ijmet 06 09_006

Ijmet 06 09_006IAEME Publication

Ěý

This document summarizes a case study analyzing and optimizing the pipe network of a cooling water system in a petrochemical plant using pipe network analysis software. The existing network was experiencing problems due to changes over time. The study involved collecting live data on flow rates and temperatures, calculating heat duties, determining optimal flow rates, creating a virtual model of the network in PIPENET software, and iteratively modifying the network through changes like line sizing. The optimized network reduced energy usage by eliminating one booster pump and improved flow distribution, saving 15% of cooling water and 27% of energy usage while maintaining required heat transfer.REVIEW OF FLOW DISTRIBUTION NETWORK ANALYSIS FOR DISCHARGE SIDE OF CENTRIFUGA...

REVIEW OF FLOW DISTRIBUTION NETWORK ANALYSIS FOR DISCHARGE SIDE OF CENTRIFUGA...ijiert bestjournal

Ěý

A computational fluid dynamics (CFD) analysis has been conducted to find the pressure losses for dividing and combining fluid flow through a junction of discharge system. Simulations are performed for a range of flow ratios and equations are developed for pressure loss coefficients at junctions. A mathematical model based on s uccessive approximations then would be employed to estimate the pressure losses. The proposed CFD based strategy can be used for the analysis of all the three pipe branches of s ome diameter are selected along with equal length so that only the effect of bend angle can be st udied. The effect of bend angle,pipe diameter,pipe length,reynolds number on the resistan ce coefficient is studied. The software used is CATIA for modeling and ANSYS fluent for analysis purpose.Optimization of Closure Law of Guide Vanes for an Operational Hydropower Plan...

Optimization of Closure Law of Guide Vanes for an Operational Hydropower Plan...Dr. Amarjeet Singh

Ěý

This paper addresses the optimization of twostage closure law of guide vanes in an operational

hydropower plant of Nepal. The mathematical model

has been established in commercial software Bentley

Hammer, whose correctness has been validated by

comparing the results with the data of experimental

load rejection test. The validated mathematical model

has been employed to find the parameters of optimum

closure pattern, which minimizes the non-linear

objective function of maximum water pressure and

maximum rotational speed of turbine.CentPumpDesign.pdf

CentPumpDesign.pdfssuserdb8927

Ěý

This thesis describes the development of a software tool to predict the performance of centrifugal pumps using loss correlation models. The tool designs pump impellers and volutes, calculates losses, and predicts off-design performance. CFD analysis is also conducted for validation. Results show good agreement between predictions, CFD simulations, and experimental data for three test pumps. Future work includes adding material properties, improved volute design, and report features to the software.A comparative study of energy management schemes for a fuel cell hybrid emerg...

A comparative study of energy management schemes for a fuel cell hybrid emerg...Asoka Technologies

Ěý

This paper presents a comparative analysis of different energy management schemes for a fuel-cell-based emergency power system of a more-electric aircraft. The fuel-cell hybrid system considered in this paper consists of fuel cells, lithium-ion batteries, and supercapacitors, along with associated dc/dc and dc/ac converters. The energy management schemes addressed are state of the art and are most commonly used energy management techniques in fuel-cell vehicle applications, and they include the following: the state machine control strategy, the rule-based fuzzy logic strategy, the classical proportional–integral control strategy, the frequency decoupling/fuzzy logic control strategy, and the equivalent consumption minimization strategy. The main criteria for performance comparison are the hydrogen consumption, the state of charges of the batteries/supercapacitors, and the overall system efficiency. Moreover, the stresses on each energy source, which impact their life cycle, are measured using a new approach based on the wavelet transform of their instantaneous power. A simulation model and an experimental test bench are developed to validate all analysis and performances.Pressure drop analysis of flow through pin fin channel

Pressure drop analysis of flow through pin fin channelIRJET Journal

Ěý

This document analyzes the pressure drop of coolant flow through pin fin channels used in electric vehicle traction inverters. Three channel designs with pin diameters of 4mm, 6mm, and 8mm were simulated using ANSYS Fluent. The pressure drop of ethylene glycol coolant was analyzed at temperatures from -17.8°C to 80°C. Pressure drop decreased with increasing temperature up to around 60°C then increased. Larger pin diameters resulted in higher pressure drops due to reduced flow area. The results provide guidance on designing coolant systems for electric vehicle inverters.Novel High Performance Stand Alone Solar PV System with High Gain, High Effic...

Novel High Performance Stand Alone Solar PV System with High Gain, High Effic...Asoka Technologies

Ěý

This document describes a novel standalone solar PV system that uses high gain, high efficiency DC-DC converters in both the power stage and battery interface. This allows the use of low voltage PV and battery sources while minimizing issues from partial shading. It also prevents overcharging and deep discharging of battery modules. The system facilitates "required power tracking" from the PV source to match load requirements without needing dump loads. Simulation and experimental results show the system achieves high performance and efficiency of 94%. The document concludes by noting limitations and opportunities for further improvement.Flow analysis of centrifugal pump using CFX solver and remedies for cavitatio...

Flow analysis of centrifugal pump using CFX solver and remedies for cavitatio...IJERA Editor

Ěý

This document discusses a study that uses computational fluid dynamics (CFD) software to analyze flow characteristics in a centrifugal pump. Specifically:

1. CFD software called CFX is used to simulate fluid flow through a 3D model of a centrifugal pump with defined boundary conditions.

2. The software helps optimize the pump design in an iterative manner based on results like pressure and velocity plots.

3. A key issue analyzed is cavitation, where vapor bubbles form and collapse in the pump due to low pressure. The document examines factors that cause cavitation and its negative effects.Comparison of Pressure Drop Characteristics of Swing Plate and Dual Plate Che...

Comparison of Pressure Drop Characteristics of Swing Plate and Dual Plate Che...IRJET Journal

Ěý

This document presents a computational fluid dynamics (CFD) analysis of the pressure drop characteristics of swing plate and dual plate check valves under varying operating conditions. The study uses ANSYS Fluent software to analyze 2D and 3D models of the valves. In 2D analysis, parameters like pressure coefficient, drag coefficient, and minimum pressure are calculated for both valves at different opening angles and Reynolds numbers. The dual plate valve is found to have lower pressure drop. 3D analysis considers different disc diameters for the swing plate valve and calculates minimum pressure to identify cavitation risks. The dual plate valve shows superior performance in terms of pressure drop and minimum pressure. For the swing plate valve, an 80% disc diameter performs best.FLUID FLOW ANALYSIS OF CENTRIFUGAL FAN BY USING FEM

FLUID FLOW ANALYSIS OF CENTRIFUGAL FAN BY USING FEMIAEME Publication

Ěý

This document presents a study analyzing the fluid flow of a centrifugal fan using finite element analysis (FEA). The study aims to compare experimental results with simulation results from ANSYS Fluent. The geometry of a forward backward curved centrifugal fan with 630mm diameter is modeled and meshed. Boundary conditions from experimental data are applied. Fluent simulations are run to obtain pressure distributions and flow patterns. Results for static pressure, efficiency, and power are compared to experimental values, showing deviations within 10-15%. The authors conclude CFD analysis can accurately validate experimental fan performance analysis when optimizing aspects like volute casing design.Centrifugal compressor anti-surge control system modelling

Centrifugal compressor anti-surge control system modellingIJECEIAES

Ěý

From the middle of XX century, natural gas is an important mineral, widely used in the energy sector. Transportation of natural gas is carried out via gas pipeline networks and compression stations. One of the key features which need to be implemented for any centrifugal gas compressor is a surge protection. This article describes the method and develops software application intended for simulation and study of surge protection system of a centrifugal compressor used in modern gas compression stations. Within the article research method, modelling environment’s block diagram, proposed algorithms and results are described. For surge cases control and prediction, Anti-surge control block implemented which based on practical experience and centrifugal compressor theory. To avoid complicated energy balancing differential equations the volumetric flow calculation algorithm proposed which is used in combination with Redlich-Kwong equation of state. Developed software’s adequacy test performed through modeling of onestage gas compression scheme at rated speed with comparison of parameters with reference commercial software and verification of the anti-surge control system.Wind Energy

Wind EnergyMd Arifujjaman, PhD, PEng

Ěý

This document describes an experimental study that compares the efficiencies of two small wind turbine systems: one based on a permanent magnet generator (PMG) and the other based on a wound rotor induction generator (WRIG). Test benches were developed for both systems using a wind turbine emulator and maximum power point tracking control. The procedure to calculate annual energy capture, losses, and efficiency using wind speed data from eight sites in Newfoundland is presented. Experimental results show the WRIG-based system provides around 5% higher efficiency than the PMG-based system, indicating it could be a better alternative for small wind energy applications.Thermodynamic optimization of

Thermodynamic optimization ofJinoop AN

Ěý

The document discusses thermodynamic optimization of screw compressors. It describes using a numerical model of fluid flow and thermodynamic processes combined with a rotor profile generation algorithm to optimize a screw compressor design for a given application and fluid. Some key points:

- The optimization considers variables like rotor profile, compressor speed, oil flow rate, temperature to maximize efficiency and minimize size depending on the compressed gas/vapor and whether the compressor is oil-free or oil-flooded.

- A constrained simplex method called the Box complex method is used to find local minima which are then used to estimate a global minimum.

- The numerical model solves conservation equations for properties like internal energy and mass flow using a RungeFLOW DISTRIBUTION NETWORK ANALYSIS FOR DISCHARGE SIDE OF CENTRIFUGAL PUMP

FLOW DISTRIBUTION NETWORK ANALYSIS FOR DISCHARGE SIDE OF CENTRIFUGAL PUMPijiert bestjournal

Ěý

A computational fluid dynamics (CFD) analysis has been conducted to f ind the pressure losses for dividing and combining fluid flow through a junction of discharge system. Si mulations are performed for a range of flow ratios and equations are developed for pressure loss coeff icients at junctions. A mathematical model based on successive approximations then would be employed to estim ate the pressure losses. The proposed CFD based strategy can be used for the analysis of all the thr ee pipe branches of some diameter are selected along with equal length so that only the effect of bend angle can be studied. The effect of bend angle,pipe diameter,pipe length,Reynolds number on the resistance coeffi cient is studied. The software used is CATIA for modeling and ANSYS fluent for analysis purpose.IRJET- A Literature Review on Investigation of Design Parameter of Cyclone Se...

IRJET- A Literature Review on Investigation of Design Parameter of Cyclone Se...IRJET Journal

Ěý

This document reviews literature on the design of cyclone separators. It discusses how cyclone separators work by using centrifugal force to separate particles from gas streams. Several studies are summarized that used computational fluid dynamics (CFD) to analyze cyclone separator design parameters and evaluate designs. One study found that a symmetrical tangential inlet design improved separator performance over a traditional single inlet design. Another study evaluated cyclone performance at different temperatures. A third study compared a single inlet design to a symmetrical dual inlet design and found the symmetrical design reduced pressure drop. The document discusses how cyclone separator design and operating parameters can impact efficiency and pressure drop.Determination of shock losses and pressure losses in ug mine openings

Determination of shock losses and pressure losses in ug mine openingsSafdar Ali

Ěý

This document discusses determining pressure and shock losses in underground mine openings using computational fluid dynamics (CFD) simulation techniques. It aims to calculate losses in different mine configurations using CFD and compare results to classical formulas. The document outlines the objective, scope, literature review on losses, and CFD methodology. It describes setting up simulations of common mine geometries like tunnels, bends, junctions, and shafts in Gambit meshing software and analyzing them in Fluent. Results are presented on velocity profiles and pressure losses for configurations like gradual contractions and expansions.Determination of shock losses and pressure losses in ug mine openings (1)

Determination of shock losses and pressure losses in ug mine openings (1)Safdar Ali

Ěý

This document discusses the determination of shock and pressure losses in underground mine openings using computational fluid dynamics (CFD) simulation techniques. The objective is to calculate losses in different mine configurations and compare results from CFD simulations to classical formulas. The document outlines the scope of the project, literature review on losses, and describes meshing mine geometries in Gambit and performing CFD simulations in Fluent. Results are presented for simulations of tunnels, bends, junctions, contractions, expansions, shafts, and regulators. CFD-generated shock loss coefficients are found to agree reasonably well with published values, except for splits/junctions and forcing shafts, which may be due to modeling limitations. The conclusion is that 3DPES Wind Magazine - New-generation DFIG power converters for 6-8 MW wind turb...

PES Wind Magazine - New-generation DFIG power converters for 6-8 MW wind turb...Ingeteam Wind Energy

Ěý

DFIG topology wind turbines have been widely used in the wind energy market during the last years to cover the medium and lower power ranges, between 2 and 4 MW. Nowadays, this fact has changed and the OEMs are developing DFIG wind turbines that could go above power rates of 6 MW.

Ingeteam’s new generation of power converters apply the most advanced control strategies, state of the art semiconductor technologies and cooling strategies that solve the main constraints of the DFIG topology, allowing for an increase in the power rate of the new wind turbines above 6 MW.

IRJET- Development of Semi-Active Suspension System-Variable Orifice based Da...

IRJET- Development of Semi-Active Suspension System-Variable Orifice based Da...IRJET Journal

Ěý

This document discusses the development of a semi-active suspension system using a variable orifice damper prototype. It begins with an abstract that outlines the research goals of examining damping resistance through different orifice sizes and using that data to develop CAD models. The document then provides background on semi-active suspension systems and variable orifice dampers before discussing the mathematical modeling of damping resistance and comparing different orifice sizes. It aims to calibrate the developed prototype to function as a mechanically adjustable semi-active suspension system.3 d flow analysis of an annular diffuser with and without struts

3 d flow analysis of an annular diffuser with and without strutsIAEME Publication

Ěý

The document summarizes a study on the 3D flow analysis of an annular diffuser with and without struts. Numerical simulations were conducted for an annular exhaust diffuser model at different inlet velocities and with or without struts. The results show that pressure recovery within the diffuser increases as flow proceeds, with pressure increasing and velocity decreasing. The presence of struts decreases the pressure recovery coefficient slightly due to increased losses, with velocity increasing along the strut portion where pressure decreases. Contour plots illustrate the velocity and pressure distributions through the diffuser. Measurement MCQs with Answers.pdf

Measurement MCQs with Answers.pdfMahesh Kumar R

Ěý

This document provides 100 multiple choice questions (MCQs) about flow measurement. It begins with an introduction stating that the MCQs are intended to help engineering students and professionals prepare for exams or brush up on fundamentals. It then lists 4 main categories of flow measurement and provides examples of applications that require flow measurement.3D FLOW ANALYSIS OF AN ANNULAR DIFFUSER WITH AND WITHOUT STRUTS

3D FLOW ANALYSIS OF AN ANNULAR DIFFUSER WITH AND WITHOUT STRUTS IAEME Publication

Ěý

Numerical investigations have been carried out for an annular type gas turbine exhaust diffuser with inlet guidevanes and with and without struts. Numerical simulations were carried out to determine the pressure recovery coefficient, for a divergence angle 13o by keeping the diffusion length constant. The flow conditions at the inlet are varied to evaluate how they affect the flow development in the passage. The velocity at inlet is varied from 80 m/s to 160 m/s in the steps of 40 m/s. In the present study a (1/6)th part of the model is considered for the analysis, due to symmetry. The results for with and without struts indicates how the pressure recovery coefficient affects the efficiency of the turbine.

Task Clarification of Pico and NanoSatellite

Task Clarification of Pico and NanoSatelliteGreeshma S

Ěý

This document discusses the clarification of tasks for pico and nanosatellites. It begins with an introduction that defines pico and nanosatellites and shows pictures of a satellite in orbit and a picosat. It then discusses the problem definition, task specification, and details of the picosat such as its orbit, mass, structure, payloads, onboard computer, data storage, attitude control system, power system, communication system, ground station, and thermal control system. It also discusses aerospace invention and concludes that the components are designed to serve specific tasks as accomplished through the picosat and nanosatellite task clarification process using convergent thinking.Need of Quality Engineering and Failure analysis Techniques

Need of Quality Engineering and Failure analysis Techniques Greeshma S

Ěý

The document discusses quality engineering (QE) and failure analysis (FA) techniques. It defines QE as engineering work related to ensuring a product meets specifications. QE aims to design robust products using techniques like Taguchi's quality loss functions and robust design methods. FA is defined as analyzing failed components to determine the root cause of failure. Several FA techniques are discussed along with the importance of FA in preventing failures in electronics. Classifying tests and understanding failure mechanisms and rates are important aspects of both QE and FA.More Related Content

Similar to Application of Micro fabricated valves based on the principles of thermo pneumatic actuation (20)

Optimization of Closure Law of Guide Vanes for an Operational Hydropower Plan...

Optimization of Closure Law of Guide Vanes for an Operational Hydropower Plan...Dr. Amarjeet Singh

Ěý

This paper addresses the optimization of twostage closure law of guide vanes in an operational

hydropower plant of Nepal. The mathematical model

has been established in commercial software Bentley

Hammer, whose correctness has been validated by

comparing the results with the data of experimental

load rejection test. The validated mathematical model

has been employed to find the parameters of optimum

closure pattern, which minimizes the non-linear

objective function of maximum water pressure and

maximum rotational speed of turbine.CentPumpDesign.pdf

CentPumpDesign.pdfssuserdb8927

Ěý

This thesis describes the development of a software tool to predict the performance of centrifugal pumps using loss correlation models. The tool designs pump impellers and volutes, calculates losses, and predicts off-design performance. CFD analysis is also conducted for validation. Results show good agreement between predictions, CFD simulations, and experimental data for three test pumps. Future work includes adding material properties, improved volute design, and report features to the software.A comparative study of energy management schemes for a fuel cell hybrid emerg...

A comparative study of energy management schemes for a fuel cell hybrid emerg...Asoka Technologies

Ěý

This paper presents a comparative analysis of different energy management schemes for a fuel-cell-based emergency power system of a more-electric aircraft. The fuel-cell hybrid system considered in this paper consists of fuel cells, lithium-ion batteries, and supercapacitors, along with associated dc/dc and dc/ac converters. The energy management schemes addressed are state of the art and are most commonly used energy management techniques in fuel-cell vehicle applications, and they include the following: the state machine control strategy, the rule-based fuzzy logic strategy, the classical proportional–integral control strategy, the frequency decoupling/fuzzy logic control strategy, and the equivalent consumption minimization strategy. The main criteria for performance comparison are the hydrogen consumption, the state of charges of the batteries/supercapacitors, and the overall system efficiency. Moreover, the stresses on each energy source, which impact their life cycle, are measured using a new approach based on the wavelet transform of their instantaneous power. A simulation model and an experimental test bench are developed to validate all analysis and performances.Pressure drop analysis of flow through pin fin channel

Pressure drop analysis of flow through pin fin channelIRJET Journal

Ěý

This document analyzes the pressure drop of coolant flow through pin fin channels used in electric vehicle traction inverters. Three channel designs with pin diameters of 4mm, 6mm, and 8mm were simulated using ANSYS Fluent. The pressure drop of ethylene glycol coolant was analyzed at temperatures from -17.8°C to 80°C. Pressure drop decreased with increasing temperature up to around 60°C then increased. Larger pin diameters resulted in higher pressure drops due to reduced flow area. The results provide guidance on designing coolant systems for electric vehicle inverters.Novel High Performance Stand Alone Solar PV System with High Gain, High Effic...

Novel High Performance Stand Alone Solar PV System with High Gain, High Effic...Asoka Technologies

Ěý

This document describes a novel standalone solar PV system that uses high gain, high efficiency DC-DC converters in both the power stage and battery interface. This allows the use of low voltage PV and battery sources while minimizing issues from partial shading. It also prevents overcharging and deep discharging of battery modules. The system facilitates "required power tracking" from the PV source to match load requirements without needing dump loads. Simulation and experimental results show the system achieves high performance and efficiency of 94%. The document concludes by noting limitations and opportunities for further improvement.Flow analysis of centrifugal pump using CFX solver and remedies for cavitatio...

Flow analysis of centrifugal pump using CFX solver and remedies for cavitatio...IJERA Editor

Ěý

This document discusses a study that uses computational fluid dynamics (CFD) software to analyze flow characteristics in a centrifugal pump. Specifically:

1. CFD software called CFX is used to simulate fluid flow through a 3D model of a centrifugal pump with defined boundary conditions.

2. The software helps optimize the pump design in an iterative manner based on results like pressure and velocity plots.

3. A key issue analyzed is cavitation, where vapor bubbles form and collapse in the pump due to low pressure. The document examines factors that cause cavitation and its negative effects.Comparison of Pressure Drop Characteristics of Swing Plate and Dual Plate Che...

Comparison of Pressure Drop Characteristics of Swing Plate and Dual Plate Che...IRJET Journal

Ěý

This document presents a computational fluid dynamics (CFD) analysis of the pressure drop characteristics of swing plate and dual plate check valves under varying operating conditions. The study uses ANSYS Fluent software to analyze 2D and 3D models of the valves. In 2D analysis, parameters like pressure coefficient, drag coefficient, and minimum pressure are calculated for both valves at different opening angles and Reynolds numbers. The dual plate valve is found to have lower pressure drop. 3D analysis considers different disc diameters for the swing plate valve and calculates minimum pressure to identify cavitation risks. The dual plate valve shows superior performance in terms of pressure drop and minimum pressure. For the swing plate valve, an 80% disc diameter performs best.FLUID FLOW ANALYSIS OF CENTRIFUGAL FAN BY USING FEM

FLUID FLOW ANALYSIS OF CENTRIFUGAL FAN BY USING FEMIAEME Publication

Ěý

This document presents a study analyzing the fluid flow of a centrifugal fan using finite element analysis (FEA). The study aims to compare experimental results with simulation results from ANSYS Fluent. The geometry of a forward backward curved centrifugal fan with 630mm diameter is modeled and meshed. Boundary conditions from experimental data are applied. Fluent simulations are run to obtain pressure distributions and flow patterns. Results for static pressure, efficiency, and power are compared to experimental values, showing deviations within 10-15%. The authors conclude CFD analysis can accurately validate experimental fan performance analysis when optimizing aspects like volute casing design.Centrifugal compressor anti-surge control system modelling

Centrifugal compressor anti-surge control system modellingIJECEIAES

Ěý

From the middle of XX century, natural gas is an important mineral, widely used in the energy sector. Transportation of natural gas is carried out via gas pipeline networks and compression stations. One of the key features which need to be implemented for any centrifugal gas compressor is a surge protection. This article describes the method and develops software application intended for simulation and study of surge protection system of a centrifugal compressor used in modern gas compression stations. Within the article research method, modelling environment’s block diagram, proposed algorithms and results are described. For surge cases control and prediction, Anti-surge control block implemented which based on practical experience and centrifugal compressor theory. To avoid complicated energy balancing differential equations the volumetric flow calculation algorithm proposed which is used in combination with Redlich-Kwong equation of state. Developed software’s adequacy test performed through modeling of onestage gas compression scheme at rated speed with comparison of parameters with reference commercial software and verification of the anti-surge control system.Wind Energy

Wind EnergyMd Arifujjaman, PhD, PEng

Ěý

This document describes an experimental study that compares the efficiencies of two small wind turbine systems: one based on a permanent magnet generator (PMG) and the other based on a wound rotor induction generator (WRIG). Test benches were developed for both systems using a wind turbine emulator and maximum power point tracking control. The procedure to calculate annual energy capture, losses, and efficiency using wind speed data from eight sites in Newfoundland is presented. Experimental results show the WRIG-based system provides around 5% higher efficiency than the PMG-based system, indicating it could be a better alternative for small wind energy applications.Thermodynamic optimization of

Thermodynamic optimization ofJinoop AN

Ěý

The document discusses thermodynamic optimization of screw compressors. It describes using a numerical model of fluid flow and thermodynamic processes combined with a rotor profile generation algorithm to optimize a screw compressor design for a given application and fluid. Some key points:

- The optimization considers variables like rotor profile, compressor speed, oil flow rate, temperature to maximize efficiency and minimize size depending on the compressed gas/vapor and whether the compressor is oil-free or oil-flooded.

- A constrained simplex method called the Box complex method is used to find local minima which are then used to estimate a global minimum.

- The numerical model solves conservation equations for properties like internal energy and mass flow using a RungeFLOW DISTRIBUTION NETWORK ANALYSIS FOR DISCHARGE SIDE OF CENTRIFUGAL PUMP

FLOW DISTRIBUTION NETWORK ANALYSIS FOR DISCHARGE SIDE OF CENTRIFUGAL PUMPijiert bestjournal

Ěý

A computational fluid dynamics (CFD) analysis has been conducted to f ind the pressure losses for dividing and combining fluid flow through a junction of discharge system. Si mulations are performed for a range of flow ratios and equations are developed for pressure loss coeff icients at junctions. A mathematical model based on successive approximations then would be employed to estim ate the pressure losses. The proposed CFD based strategy can be used for the analysis of all the thr ee pipe branches of some diameter are selected along with equal length so that only the effect of bend angle can be studied. The effect of bend angle,pipe diameter,pipe length,Reynolds number on the resistance coeffi cient is studied. The software used is CATIA for modeling and ANSYS fluent for analysis purpose.IRJET- A Literature Review on Investigation of Design Parameter of Cyclone Se...

IRJET- A Literature Review on Investigation of Design Parameter of Cyclone Se...IRJET Journal

Ěý

This document reviews literature on the design of cyclone separators. It discusses how cyclone separators work by using centrifugal force to separate particles from gas streams. Several studies are summarized that used computational fluid dynamics (CFD) to analyze cyclone separator design parameters and evaluate designs. One study found that a symmetrical tangential inlet design improved separator performance over a traditional single inlet design. Another study evaluated cyclone performance at different temperatures. A third study compared a single inlet design to a symmetrical dual inlet design and found the symmetrical design reduced pressure drop. The document discusses how cyclone separator design and operating parameters can impact efficiency and pressure drop.Determination of shock losses and pressure losses in ug mine openings

Determination of shock losses and pressure losses in ug mine openingsSafdar Ali

Ěý

This document discusses determining pressure and shock losses in underground mine openings using computational fluid dynamics (CFD) simulation techniques. It aims to calculate losses in different mine configurations using CFD and compare results to classical formulas. The document outlines the objective, scope, literature review on losses, and CFD methodology. It describes setting up simulations of common mine geometries like tunnels, bends, junctions, and shafts in Gambit meshing software and analyzing them in Fluent. Results are presented on velocity profiles and pressure losses for configurations like gradual contractions and expansions.Determination of shock losses and pressure losses in ug mine openings (1)

Determination of shock losses and pressure losses in ug mine openings (1)Safdar Ali

Ěý

This document discusses the determination of shock and pressure losses in underground mine openings using computational fluid dynamics (CFD) simulation techniques. The objective is to calculate losses in different mine configurations and compare results from CFD simulations to classical formulas. The document outlines the scope of the project, literature review on losses, and describes meshing mine geometries in Gambit and performing CFD simulations in Fluent. Results are presented for simulations of tunnels, bends, junctions, contractions, expansions, shafts, and regulators. CFD-generated shock loss coefficients are found to agree reasonably well with published values, except for splits/junctions and forcing shafts, which may be due to modeling limitations. The conclusion is that 3DPES Wind Magazine - New-generation DFIG power converters for 6-8 MW wind turb...

PES Wind Magazine - New-generation DFIG power converters for 6-8 MW wind turb...Ingeteam Wind Energy

Ěý

DFIG topology wind turbines have been widely used in the wind energy market during the last years to cover the medium and lower power ranges, between 2 and 4 MW. Nowadays, this fact has changed and the OEMs are developing DFIG wind turbines that could go above power rates of 6 MW.

Ingeteam’s new generation of power converters apply the most advanced control strategies, state of the art semiconductor technologies and cooling strategies that solve the main constraints of the DFIG topology, allowing for an increase in the power rate of the new wind turbines above 6 MW.

IRJET- Development of Semi-Active Suspension System-Variable Orifice based Da...

IRJET- Development of Semi-Active Suspension System-Variable Orifice based Da...IRJET Journal

Ěý

This document discusses the development of a semi-active suspension system using a variable orifice damper prototype. It begins with an abstract that outlines the research goals of examining damping resistance through different orifice sizes and using that data to develop CAD models. The document then provides background on semi-active suspension systems and variable orifice dampers before discussing the mathematical modeling of damping resistance and comparing different orifice sizes. It aims to calibrate the developed prototype to function as a mechanically adjustable semi-active suspension system.3 d flow analysis of an annular diffuser with and without struts

3 d flow analysis of an annular diffuser with and without strutsIAEME Publication

Ěý

The document summarizes a study on the 3D flow analysis of an annular diffuser with and without struts. Numerical simulations were conducted for an annular exhaust diffuser model at different inlet velocities and with or without struts. The results show that pressure recovery within the diffuser increases as flow proceeds, with pressure increasing and velocity decreasing. The presence of struts decreases the pressure recovery coefficient slightly due to increased losses, with velocity increasing along the strut portion where pressure decreases. Contour plots illustrate the velocity and pressure distributions through the diffuser. Measurement MCQs with Answers.pdf

Measurement MCQs with Answers.pdfMahesh Kumar R

Ěý

This document provides 100 multiple choice questions (MCQs) about flow measurement. It begins with an introduction stating that the MCQs are intended to help engineering students and professionals prepare for exams or brush up on fundamentals. It then lists 4 main categories of flow measurement and provides examples of applications that require flow measurement.3D FLOW ANALYSIS OF AN ANNULAR DIFFUSER WITH AND WITHOUT STRUTS

3D FLOW ANALYSIS OF AN ANNULAR DIFFUSER WITH AND WITHOUT STRUTS IAEME Publication

Ěý

Numerical investigations have been carried out for an annular type gas turbine exhaust diffuser with inlet guidevanes and with and without struts. Numerical simulations were carried out to determine the pressure recovery coefficient, for a divergence angle 13o by keeping the diffusion length constant. The flow conditions at the inlet are varied to evaluate how they affect the flow development in the passage. The velocity at inlet is varied from 80 m/s to 160 m/s in the steps of 40 m/s. In the present study a (1/6)th part of the model is considered for the analysis, due to symmetry. The results for with and without struts indicates how the pressure recovery coefficient affects the efficiency of the turbine.

Optimization of Closure Law of Guide Vanes for an Operational Hydropower Plan...

Optimization of Closure Law of Guide Vanes for an Operational Hydropower Plan...Dr. Amarjeet Singh

Ěý

A comparative study of energy management schemes for a fuel cell hybrid emerg...

A comparative study of energy management schemes for a fuel cell hybrid emerg...Asoka Technologies

Ěý

Novel High Performance Stand Alone Solar PV System with High Gain, High Effic...

Novel High Performance Stand Alone Solar PV System with High Gain, High Effic...Asoka Technologies

Ěý

PES Wind Magazine - New-generation DFIG power converters for 6-8 MW wind turb...

PES Wind Magazine - New-generation DFIG power converters for 6-8 MW wind turb...Ingeteam Wind Energy

Ěý

More from Greeshma S (9)

Task Clarification of Pico and NanoSatellite

Task Clarification of Pico and NanoSatelliteGreeshma S

Ěý

This document discusses the clarification of tasks for pico and nanosatellites. It begins with an introduction that defines pico and nanosatellites and shows pictures of a satellite in orbit and a picosat. It then discusses the problem definition, task specification, and details of the picosat such as its orbit, mass, structure, payloads, onboard computer, data storage, attitude control system, power system, communication system, ground station, and thermal control system. It also discusses aerospace invention and concludes that the components are designed to serve specific tasks as accomplished through the picosat and nanosatellite task clarification process using convergent thinking.Need of Quality Engineering and Failure analysis Techniques

Need of Quality Engineering and Failure analysis Techniques Greeshma S

Ěý

The document discusses quality engineering (QE) and failure analysis (FA) techniques. It defines QE as engineering work related to ensuring a product meets specifications. QE aims to design robust products using techniques like Taguchi's quality loss functions and robust design methods. FA is defined as analyzing failed components to determine the root cause of failure. Several FA techniques are discussed along with the importance of FA in preventing failures in electronics. Classifying tests and understanding failure mechanisms and rates are important aspects of both QE and FA.FlexRay

FlexRayGreeshma S

Ěý

This document summarizes a presentation about FlexRay, an automotive network communications protocol. FlexRay uses a time-triggered protocol and is designed to be faster and more reliable than CAN and TTP. It operates using a layered architecture with physical, transfer, presentation and application layers. FlexRay frames have a defined format including fields for frame ID, CRC and cycle counter. FlexRay supports both static and dynamic segments for time-division multiple access. FlexRay version 3.0 introduced improvements like single coldstart nodes and wake-up capability during operation. FlexRay is well-suited for medium data rates in applications like X-by-wire systems.Packaging issues of optical component

Packaging issues of optical componentGreeshma S

Ěý

The document discusses optical packaging and integration of optical components onto printed circuit boards. It describes different types of semiconductor packaging and issues with optical packaging, including fabrication challenges, coupling of devices to boards, assembly, and reliability testing. The document proposes a roadmap for developing optical printed circuit boards and concludes that lithium niobate is well-suited as an optical packaging material and that optical packaging offers advantages over electrical packaging.ARM Boards for DSP Applications

ARM Boards for DSP ApplicationsGreeshma S

Ěý

The document discusses the ARM9E-S and DM3730 processor boards and their suitability for digital signal processing applications. It describes the ARM9E-S architecture, the DM3730 functional blocks and software architecture. It also covers digital signal representation, common DSP algorithms like FIR/IIR filters and the DFT, and how these can be efficiently implemented using the ARM9E-S and DM3730 instruction sets and hardware features. In conclusion, it states that the DM3730 provides a low power and high performance platform for DSP.Vector control of Cycloconverters-WFSM Drive

Vector control of Cycloconverters-WFSM DriveGreeshma S

Ěý

This document presents a presentation on vector control of cycloconverters for wound-field synchronous motor (WFSM) drives. It introduces vector control and cycloconverters, and how they can be applied to asynchronous motors. The presentation covers vector controlled implementation, phasor diagrams, feedback signal processing for vector control, computational equations, advantages of increased control and performance, and disadvantages like steady-state performance and complex feedback processing. It concludes that vector control with a voltage source converter can operate WFSM at unity or leading power factor for high performance dynamic applications.Pulse Generator

Pulse GeneratorGreeshma S

Ěý

This presentation discusses pulse generators. It begins with an introduction that defines pulses and describes different types of waves including square waves. It then explains the circuitry of an astable multivibrator and how it can be used to generate pulses. Characteristics of pulse generators like rise time, width and repetition rate are covered. Applications include driving devices and digital communication. Advantages include simple control systems and flexibility of time parameters, while disadvantages include amplitude drop during pulses. The presentation concludes with a summary of the content.JHDL BITS: THE INTEGRATION OF TWO PROMINENT FPGA DESIGN TOOLS

JHDL BITS: THE INTEGRATION OF TWO PROMINENT FPGA DESIGN TOOLSGreeshma S

Ěý

The document discusses JHDL Bits, which integrates the FPGA design tools JHDL and JBits. It allows high-level circuit design using JHDL alongside low-level control of resource placement and routing using JBits. This provides researchers a platform to explore interactions with FPGA bitstreams. The document outlines the JHDL Bits design flow and implementation, advantages like portability, and areas for improvement like execution time and interface flexibility with the router.Image Sensors on Digital Camera

Image Sensors on Digital CameraGreeshma S

Ěý

The document discusses the components and functioning of image sensors in digital cameras. It explains that digital cameras use either CCD or CMOS image sensors to convert optical images into electronic signals. The presentation covers the need analysis, operation analysis, functional analysis, and feasibility analysis required for developing image sensors for digital cameras. It also discusses the working of image sensors, advantages and disadvantages of digital cameras over traditional cameras, and concludes with the increasing applications of image sensors in various industries.Application of Micro fabricated valves based on the principles of thermo pneumatic actuation

- 1. M. S. Ramaiah School of Advanced Studies 1 M. Sc. (Engg.) in Electronics System Design Engineering GREESHMA S CWB0913004 , FT-2013 4thModule Presentation Module code : ESE2513Module name : Low Voltage ElectronicsModule leader: Ms. Nireeksha/ Ms. Malathi Presentation on : 14/02/2014

- 2. M. S. Ramaiah School of Advanced Studies 2 Application of Micro fabricated valves based on the principles of thermo pneumatic actuation Presentation on

- 3. M. S. Ramaiah School of Advanced Studies 3 •ABSTRACT •INTRODUCTION •THERMOPNEUMATICMICROVALVETECHNOLOGY •REFRIGERATIONAPPLICATION •SEMICONDUCTORPROCESSAPPLICATION •MASSFLOWMEASUREMENTPRINCIPLE •ADVANTAGES •DISADVANTAGES •CONCLUSION •REFERENCES Overview

- 4. M. S. Ramaiah School of Advanced Studies 4 Abstract Intermsofcontrolanddistributionofliquidsandgases(microfluidics),MEMS- baseddevicesoffersopportunitiestoachieveincreasedperformanceandhigherlevelsoffunctionalintegration,atlowercost,withdecreasedsizeandincreasedreliability Microfluidicactuatorsincludedistributionmicrochannelsandorifices,microvalves, micropumps,andmicrocompressors Relatedmicrosensorsarerequiredtomeasuretemperature,flow,pressure, viscosity,anddensity Abriefcomparisontootheractuationtechniquesismade,scienceandtechnologyofsilicon-basedthermopneumaticmicrovalves Expansionvalvesforrefrigerationcontrol

- 5. M. S. Ramaiah School of Advanced Studies 5Introduction Actuatorssuchaspumps,compressors,andvalvesareusedtoalterthestateofthefluidpressure,temperature,orflow MicrofabricationtechniquescreatedforthesemiconductorintegratedcircuitindustryhavefoundnewapplicationsinMEMSresearch,developmentandmanufacture Microvalvesareaprimarycomponentofmicrofluidicsystems Actuatorsrelyonavarietyofactivationmechanism,suchaselectromagnetic, electrostatic,pneumatic,bimetallicalloys,shape-memoryalloys(SMA),electro- chemicalandthermopnematic Distributionchannels,suchasorificesandmicrochannels,carrythefluidfromoneportionofthesystemtoanother

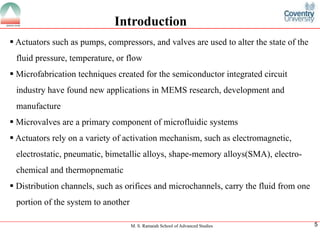

- 6. M. S. Ramaiah School of Advanced Studies 6Thermopneumatic Microvalve TechnologyFigure1CrosssectionofaThermopneumaticallyActuatedMicrovalve Figure2DrillholesinPyrex Waferultrasonically Figure3MetalizePyrexwafer Figure4DefinemembraneLithographically(goldoxides, Photo-resistmasks) Figure5EtchmembranewaferinKOH;stripmaskingmaterialsFigure6Defineorificewaferlithographically Figure7Etchorificewaferin KOH Figure8Fabricationsequencefora normallyopen,thermopneumatic valves

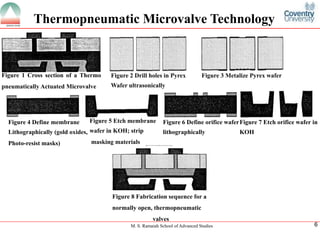

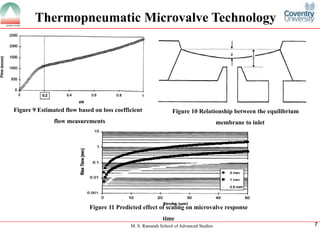

- 7. M. S. Ramaiah School of Advanced Studies 7 Thermopneumatic Microvalve Technology Figure 9 Estimated flow based on loss coefficient flow measurements Figure 10 Relationship between the equilibrium membrane to inlet Figure 11 Predicted effect of scaling on microvalve responsetime

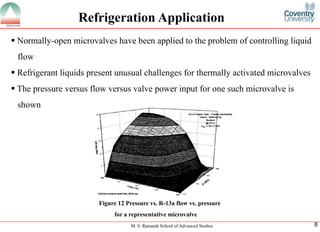

- 8. M. S. Ramaiah School of Advanced Studies 8Refrigeration Application Normally-open microvalves have been applied to the problem of controlling liquid flow Refrigerant liquids present unusual challenges for thermally activated microvalves The pressure versus flow versus valve power input for one such microvalve is shown Figure 12 Pressure vs. R-13a flow vs. pressure for a representative microvalve

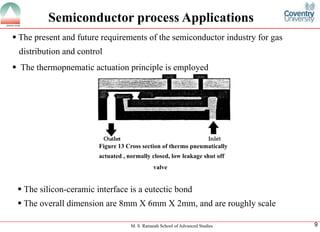

- 9. M. S. Ramaiah School of Advanced Studies 9 Semiconductor process Applications The present and future requirements of the semiconductor industry for gas distribution and control The thermopnematic actuation principle is employedFigure 13 Cross section of thermo pneumaticallyactuated , normally closed, low leakage shut offvalve The silicon-ceramic interface is a eutectic bond The overall dimension are 8mm X 6mm X 2mm, and are roughly scale

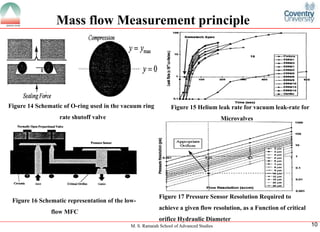

- 10. M. S. Ramaiah School of Advanced Studies 10Mass flow Measurement principleFigure 14 Schematic of O-ring used in the vacuum ring rate shutoff valve Figure 15 Helium leak rate for vacuum leak-rate for Microvalves Figure 16 Schematic representation of the low- flow MFC Figure 17 Pressure Sensor Resolution Required to achieve a given flow resolution, as a Function of criticalorifice Hydraulic Diameter

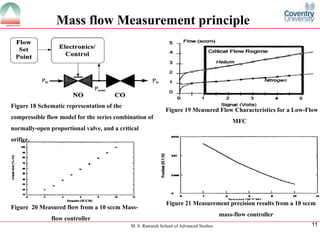

- 11. M. S. Ramaiah School of Advanced Studies 11Mass flow Measurement principleFigure 18 Schematic representation of the compressible flow model for the series combination of normally-open proportional valve, and a critical orifice. Figure 19 Measured Flow Characteristics for a Low-FlowMFCFigure 20 Measured flow from a 10 sccm Mass- flow controller Figure 21 Measurement precision results from a 10 sccm mass-flow controller

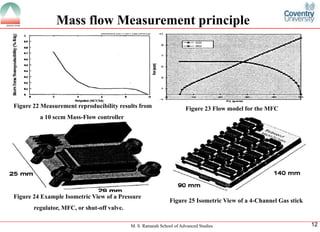

- 12. M. S. Ramaiah School of Advanced Studies 12 Mass flow Measurement principleFigure 22 Measurement reproducibility results from a 10 sccm Mass-Flow controllerFigure 23 Flow model for the MFC Figure 24 Example Isometric View of a Pressureregulator, MFC, or shut-off valve. Figure 25 Isometric View of a 4-Channel Gas stick

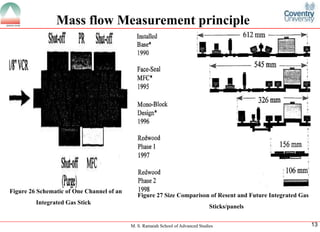

- 13. M. S. Ramaiah School of Advanced Studies 13Mass flow Measurement principle Figure 26 Schematic of One Channel of an Integrated Gas Stick Figure 27 Size Comparison of Resent and Future Integrated Gas Sticks/panels

- 14. M. S. Ramaiah School of Advanced Studies 14Advantages Increasedperformance Higherlevelsoffunctionalintegration HigherResolution Decreasedsize IncreasedreliabilityDisadvantages Thepowerrequiredforactuation Responsespeed Theeffectofshrinkingsize Structuralparameters Choiceofthermopneumaticliquid

- 15. M. S. Ramaiah School of Advanced Studies 15Conclusion The science and technology required to design and fabricate flow distribution and control devices suitable for semiconductor processing industry Components such as pressure-based flow models, critical orifices, pressure temperature sensors normally-closed vacuum leak rate shut off valves, have developed These components are combined at higher level into integrated gas panels which has benefit of smaller size, lower cost, higher resolution , materials compatibility and lower defect generation which are among the attributes of the successful application of MEMS-based technology

- 16. M. S. Ramaiah School of Advanced Studies 16References Elisabeth verpoorte and nicof.de.rooij,fellow, (2003). Microfluidics Meets MEMS. 6th ed. Switzerland: University of Neuchâtel. 930-953 Albert K. Henning (1998).Microfluidic MEMS. CA: -. 471-486

- 17. M. S. Ramaiah School of Advanced Studies 17